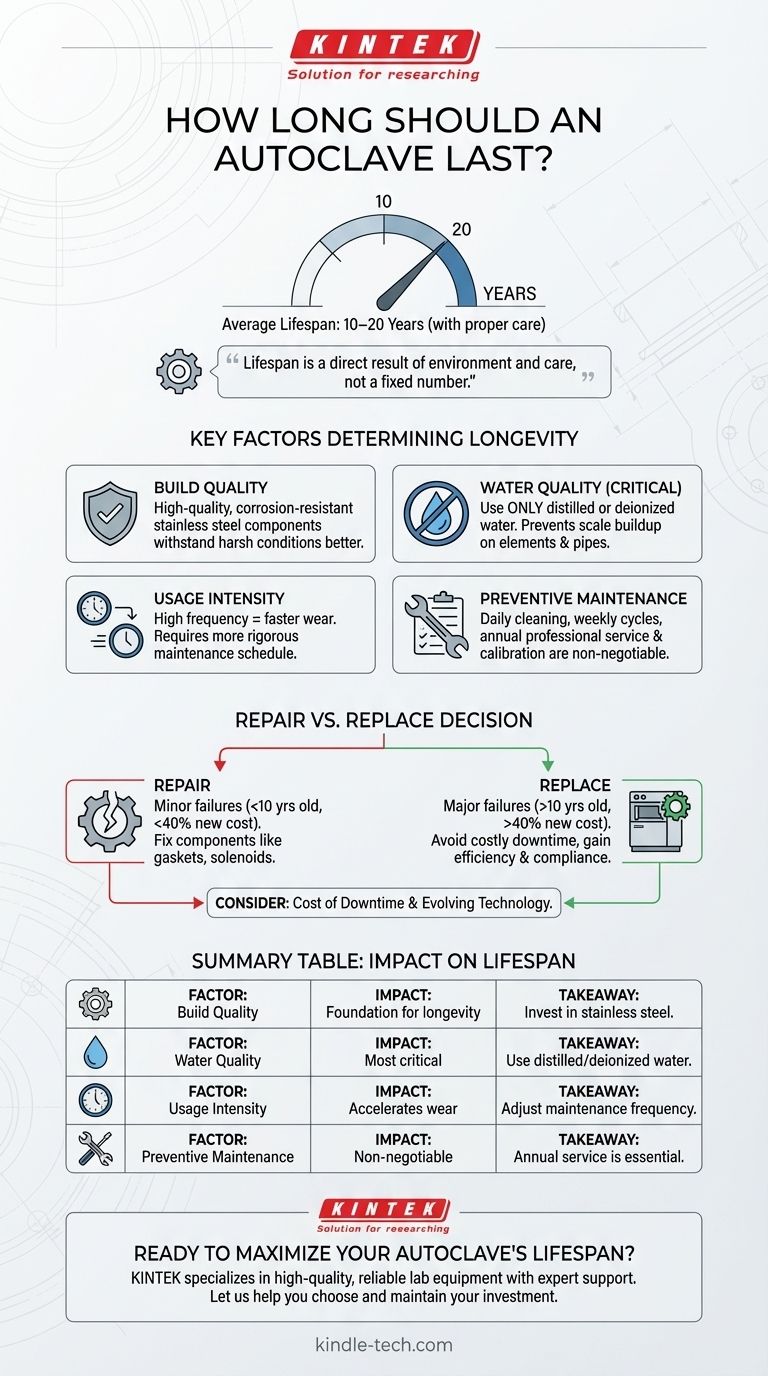

An autoclave's lifespan is measured in years, not the minutes of a single cycle. A quality, well-maintained autoclave can be expected to last between 10 and 20 years. This impressive service life is not a guarantee; it is the direct result of build quality, usage patterns, and, most critically, the consistency of its maintenance regimen.

An autoclave's lifespan is not a fixed number but a direct result of its environment and care. While a decade is a reasonable expectation, factors like water quality and consistent preventive maintenance are what truly determine if it reaches or exceeds 15-20 years of reliable service.

The Key Factors That Determine Autoclave Longevity

The difference between an autoclave that fails in seven years and one that operates flawlessly for fifteen comes down to a few key variables. Understanding these allows you to control the destiny of your equipment.

Build Quality and Initial Investment

The materials used in construction are paramount. Models with high-quality, corrosion-resistant stainless steel chambers, pipes, and valves will naturally withstand the harsh environment of high-pressure steam far better than lower-cost alternatives.

A higher initial investment often correlates with more robust components and superior engineering, providing a better foundation for a long service life.

Water Quality: The Silent Killer

This is arguably the single most important factor in autoclave health. Using tap water, or even poorly filtered water, introduces minerals like calcium and magnesium into the system.

These minerals build up as scale inside the chamber, on heating elements, and within narrow pipes and valves. This scale insulates heating elements, causing them to work harder and burn out, and clogs critical components, leading to malfunction.

For this reason, using only distilled or deionized water is the most effective action you can take to prolong an autoclave's life.

Usage Intensity

An autoclave in a busy hospital sterilization department running 20 cycles a day will experience more wear and tear than a unit in a small dental clinic running twice a day.

Higher frequency means more cycles of heating and cooling, pressurization, and mechanical stress on gaskets, seals, and valves. While built for this, higher usage necessitates a more rigorous maintenance schedule.

The Power of Preventive Maintenance

An autoclave is not a "set it and forget it" device. A consistent maintenance schedule is non-negotiable for achieving a long lifespan.

This includes daily wipe-downs of the chamber, weekly cleaning cycles, regular inspection and replacement of the door gasket, and, critically, an annual service and calibration by a qualified technician. This professional check-up can identify failing parts before they cause a catastrophic breakdown.

Understanding the Trade-offs: Repair vs. Replace

As an autoclave ages, you will inevitably face the decision of whether to repair a failing component or replace the entire unit.

The Cost of Downtime

When an older autoclave fails, the cost is not just the repair bill. The primary cost is often the operational downtime. For a busy clinic or lab, being unable to sterilize instruments can halt operations entirely, leading to lost revenue and productivity that can quickly exceed the cost of the repair itself.

Diminishing Returns on Repairs

Early in an autoclave's life, replacing a gasket or a solenoid is a simple, cost-effective repair. However, after 10-12 years, you may face failures of major, expensive components like the steam generator, chamber, or main control board.

When a single repair costs 40-50% of the price of a brand new unit, it is often more financially prudent to invest in a new machine with a full warranty.

Evolving Technology and Compliance

Newer autoclaves are often more energy-efficient, have faster cycles, and feature superior data logging and user interfaces. Sticking with a 20-year-old machine may mean you are missing out on efficiency gains and features that simplify regulatory compliance.

Making the Right Choice for Your Goal

Your strategy should be guided by your specific operational needs and financial planning.

- If your primary focus is maximizing the return on a new purchase: Invest in a model with a high-quality stainless steel chamber and commit to using only distilled or deionized water from day one.

- If your primary focus is extending the life of an existing unit: Immediately implement a strict daily and weekly cleaning schedule and sign up for an annual preventive maintenance contract with a qualified technician.

- If you are deciding whether to repair or replace an older autoclave: Calculate the repair cost as a percentage of a new unit's price; if it exceeds 40% and the machine is over 10 years old, replacement is almost always the wiser long-term decision.

By treating your autoclave as a dynamic system that requires consistent care, you transform it from a depreciating expense into a long-term, reliable partner in your work.

Summary Table:

| Factor | Impact on Lifespan | Key Takeaway |

|---|---|---|

| Build Quality | Foundation for longevity | Invest in corrosion-resistant stainless steel components |

| Water Quality | Most critical factor | Use only distilled or deionized water to prevent scale buildup |

| Usage Intensity | Accelerates wear and tear | Adjust maintenance frequency based on cycle volume |

| Preventive Maintenance | Non-negotiable for longevity | Annual professional service and daily/weekly cleaning are essential |

Ready to maximize your autoclave's lifespan? KINTEK specializes in high-quality lab equipment and consumables designed for long-term reliability. Our autoclaves feature corrosion-resistant stainless steel construction and are backed by expert maintenance support. Let us help you choose the right equipment and implement a preventive care plan that extends your investment. Contact our lab equipment specialists today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- Is an autoclave a medical device? Understanding Regulatory Classification and Intended Use

- What is the research value of using a high-pressure autoclave for curing geopolymer materials? Unlocking Durability

- Why is a PTFE-lined hydrothermal autoclave required for the preparation of Pt/Nb-TiO2 electrocatalysts?

- What is the role of the Bowie-Dick-Test in waste decontamination? Focus on Lab Efficiency & Compliance

- What is the function of a High-Pressure Hydrothermal Autoclave in preparing mesoporous hydroxyapatite? Key Insights

- What is the oven in a bio lab? The Key to Sterilization and Precise Sample Drying

- What is the difference between 121 and 134 autoclave? Choose the Right Sterilization Cycle

- How do high-pressure autoclaves facilitate the synthesis of mesoporous hydroxyapatite powders? Optimize Your Biomaterials