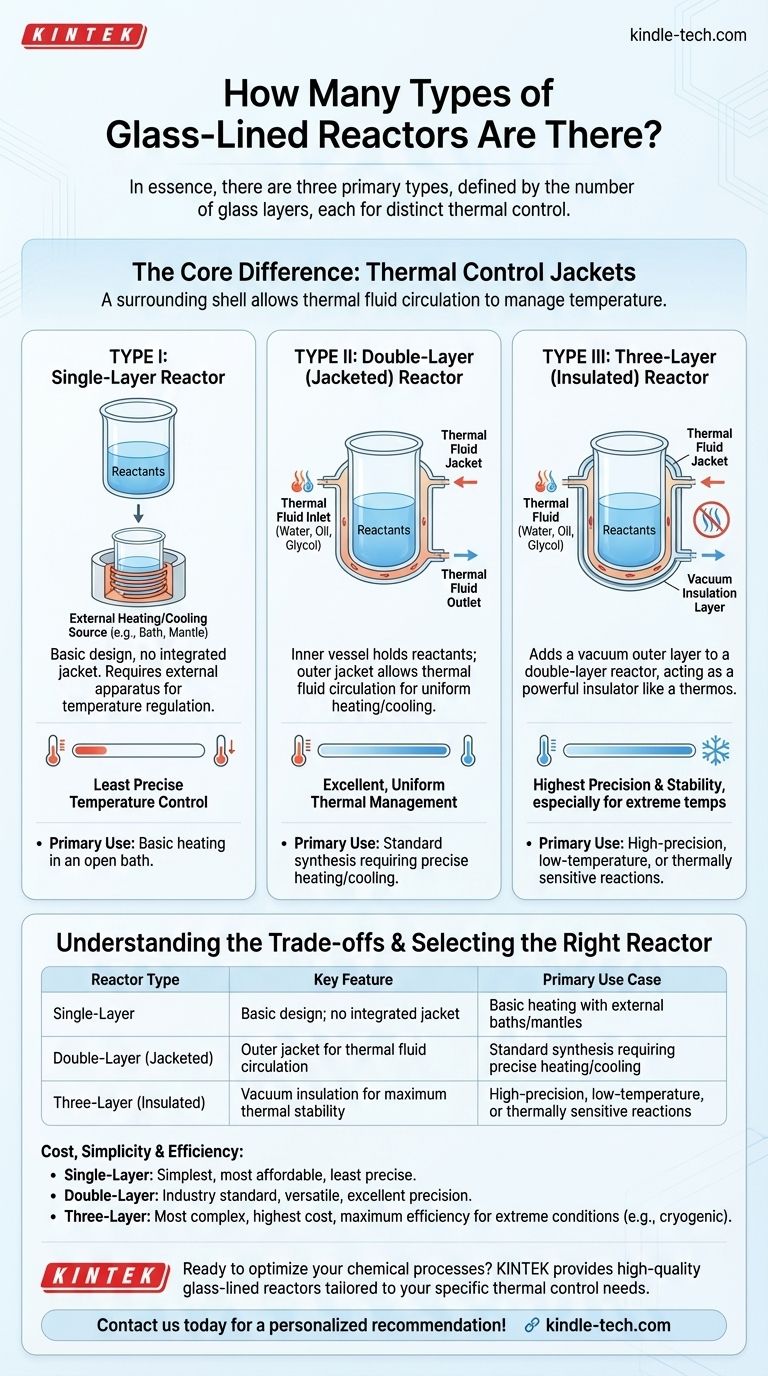

In essence, there are three primary types of glass-lined reactors. These are defined by the number of glass layers they possess: single-layer, double-layer (jacketed), and three-layer (jacketed and insulated). Each design serves a distinct purpose related to thermal control for chemical processes.

The choice between reactor types is not about quality, but about the required method and precision of temperature control. The number of layers directly corresponds to the mechanism for heating or cooling the reaction mixture inside the vessel.

The Core Difference: Thermal Control Jackets

The fundamental distinction between these reactor types is the presence and configuration of an outer "jacket." This jacket is a shell that surrounds the primary reaction vessel, creating a space through which a thermal fluid can be circulated to manage temperature.

Type I: The Single-Layer Reactor

A single-layer reactor is the most basic design, consisting of just one wall of glass.

Heating and cooling are not integrated. Instead, the vessel must be placed into an external heating or cooling source, such as a heating mantle or a water/oil bath, to regulate the temperature of its contents.

Type II: The Double-Layer (Jacketed) Reactor

This is the most common type of glass reactor. It features an inner vessel that holds the reactants and an outer glass "jacket" fused around it.

A thermal fluid (like water, oil, or a glycol mixture) is pumped through the space between the two layers. This circulation provides precise and uniform heating or cooling to the inner vessel, making it ideal for most standard chemical synthesis applications.

Type III: The Three-Layer (Insulated) Reactor

This design adds a third, outermost layer to a double-layer reactor. The space between the second and third layers is a vacuum.

This vacuum jacket acts as a powerful insulator, much like a thermos. It prevents heat exchange with the surrounding environment, making it exceptionally efficient for reactions requiring extremely low temperatures or highly stable thermal conditions. It also prevents condensation or frost from forming on the reactor's exterior during cryogenic work.

Understanding the Trade-offs

Choosing the wrong reactor type can lead to inefficient processes, poor results, or unnecessary expense. The decision balances performance needs with operational complexity.

Cost and Simplicity

The single-layer reactor is the simplest and most affordable option. The three-layer reactor is the most complex and carries the highest initial cost due to its sophisticated construction.

Precision of Temperature Control

The single-layer reactor offers the least precise temperature control, as it relies entirely on an external apparatus.

The double-layer reactor provides excellent, uniform thermal management suitable for the vast majority of laboratory and production needs.

The three-layer reactor offers the highest level of thermal precision and stability, especially for demanding processes at extreme temperatures.

Operational Efficiency

For very low-temperature reactions, a three-layer reactor is far more efficient. Its vacuum insulation minimizes the cooling load required to maintain the target temperature, saving energy and improving performance. A double-layer reactor used for the same task would constantly "fight" the ambient room temperature.

Selecting the Right Reactor for Your Process

Your choice should be dictated entirely by the thermal demands of your application.

- If your primary focus is basic heating in an open bath: A single-layer reactor is a simple and cost-effective solution.

- If your primary focus is standard synthesis requiring controlled heating and cooling: A double-layer (jacketed) reactor is the industry standard and the most versatile choice.

- If your primary focus is high-precision, low-temperature, or thermally sensitive reactions: A three-layer reactor provides the insulation and stability necessary for optimal results and efficiency.

Understanding the role of each layer empowers you to select the reactor that provides the precise thermal control your process demands.

Summary Table:

| Reactor Type | Key Feature | Primary Use Case |

|---|---|---|

| Single-Layer | Basic design; no integrated jacket | Basic heating with external baths/mantles |

| Double-Layer (Jacketed) | Outer jacket for thermal fluid circulation | Standard synthesis requiring precise heating/cooling |

| Three-Layer (Insulated) | Vacuum insulation for maximum thermal stability | High-precision, low-temperature, or thermally sensitive reactions |

Ready to optimize your chemical processes with the right glass-lined reactor?

KINTEK specializes in providing high-quality lab equipment, including a full range of glass-lined reactors tailored to your specific thermal control needs. Whether you're scaling up production or require precision for sensitive reactions, our experts can help you select the ideal equipment to enhance efficiency, ensure safety, and improve yields.

Contact us today to discuss your application and get a personalized recommendation!

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Super Sealed Electrolytic Electrochemical Cell

People Also Ask

- Why is it necessary to ensure an oxygen-free environment in a pyrolysis reactor? Maximize Bio-Oil & Syngas Yields

- Why is a high-pressure hydrothermal reactor used to treat MgAl-LDH? Enhance Your Material's Structural Precision

- How does the design of the TEAR implement Process Intensification (PI) principles? Enhance Reactor Efficiency

- What role do chemical reactors or heating and stirring devices play in the synthesis of PIN precursor resins?

- How much does a biomass pyrolysis reactor cost? A Price Guide from Lab to Industrial Scale

- What role does a high-pressure reactor play in preparing microporous ceramics? Achieve Precise Si-O-C Microstructures

- How does a high-pressure hydrothermal synthesis reactor assist in reducing hazardous substances? Scavenging Formaldehyde

- What is the role of a heating reactor with a vacuum system in cable material preparation? Ensure Flawless Insulation