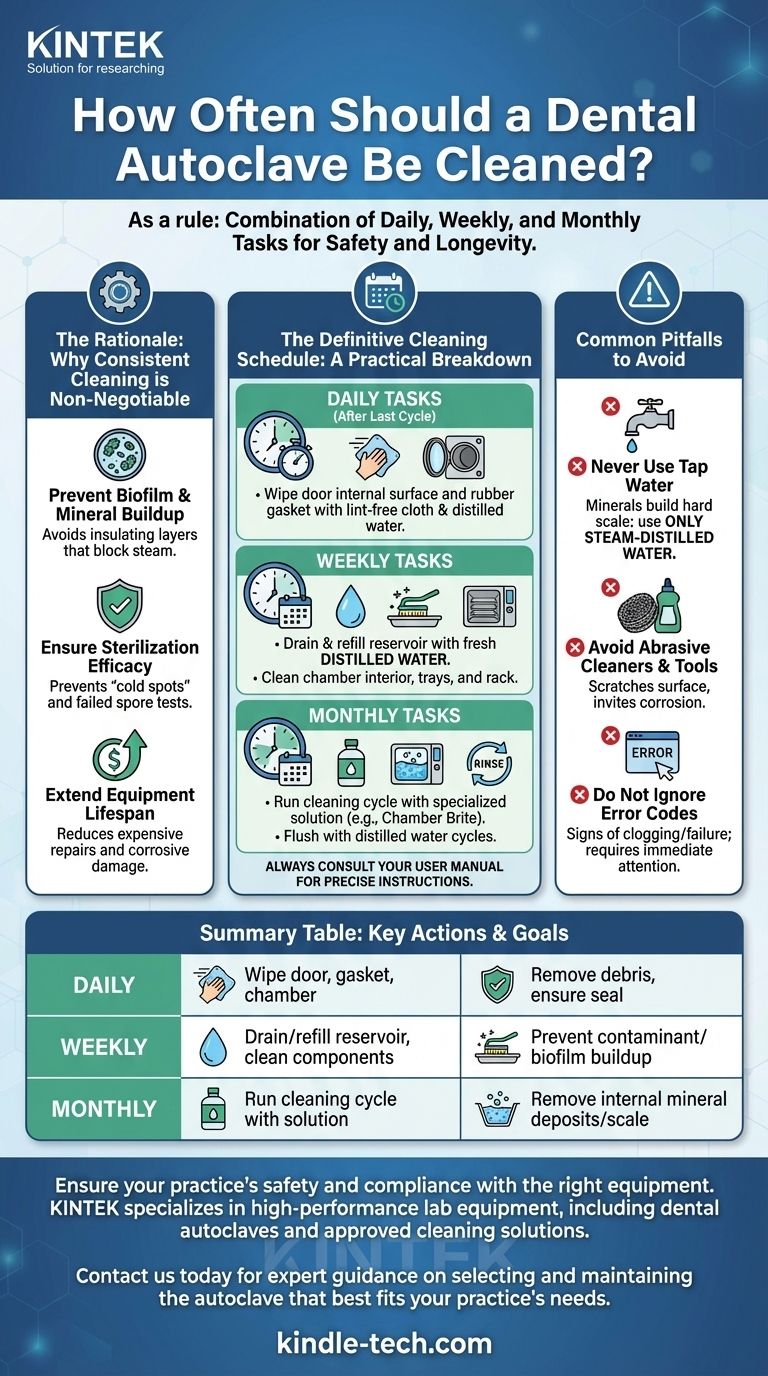

As a rule, dental autoclaves require a combination of daily, weekly, and monthly cleaning tasks. This multi-tiered schedule is not arbitrary; it is a fundamental requirement for ensuring sterilization is effective, preventing premature equipment failure, and maintaining compliance with health and safety standards.

The core principle to understand is that autoclave cleaning is not just about appearances. It is a critical function of your infection control protocol, directly impacting sterilization efficacy, equipment longevity, and ultimately, patient safety.

The Rationale: Why a Consistent Schedule is Non-Negotiable

Failing to adhere to a regular cleaning schedule introduces significant risks to your practice. The consequences extend far beyond simple maintenance issues.

To Prevent Biofilm and Mineral Buildup

Every sterilization cycle introduces water and contaminants into the chamber. Over time, this creates a buildup of mineral deposits (especially if using tap water) and organic debris, known as biofilm.

This residue can bake onto the chamber walls, trays, and critical sensors, creating a layer that insulates against the sterilizing agent (steam).

To Ensure Sterilization Efficacy

The primary function of an autoclave is to kill all microorganisms. When mineral or biofilm buildup occurs, it can create "cold spots" inside the chamber where steam cannot penetrate effectively.

This compromises the entire sterilization process, potentially leaving instruments contaminated and putting patients at risk. It is a leading cause of failed spore tests.

To Extend Equipment Lifespan

An autoclave is a significant financial investment. Mineral deposits and residue are highly corrosive to the stainless steel chamber and can clog sensitive valves, filters, and steam lines.

Regular cleaning prevents this corrosive damage, drastically reducing the likelihood of expensive repairs and extending the operational life of the unit.

The Definitive Cleaning Schedule: A Practical Breakdown

While you must always consult your specific model's user manual for precise instructions, the following schedule represents the industry best practice for most tabletop steam autoclaves.

Daily Tasks (After the Last Cycle)

At the end of each day, perform a basic wipe-down. This takes only a minute but prevents the accumulation of debris.

Wipe the internal surface of the door and the rubber door gasket with a lint-free cloth and distilled water. This ensures a proper seal for the next day's cycles.

Weekly Tasks

Once a week, perform a more thorough cleaning of the chamber and its components.

Drain the water reservoir completely and refill it with fresh distilled water. Clean the inside of the chamber with a mild, non-abrasive cleaning agent recommended by the manufacturer. Remove and scrub the trays, rack, and plate using a non-metallic brush.

Monthly Tasks

Your monthly cleaning involves a deeper flush of the entire system to remove any internal buildup that daily and weekly cleaning can't reach.

Run a cleaning cycle using a specialized autoclave cleaning solution (such as Chamber Brite or a similar product). After the cycle, drain the reservoir, wipe the chamber clean, and run one or two distilled water-only cycles to flush any residual cleaning agent from the system.

Common Pitfalls to Avoid

Correct maintenance is as much about what you don't do as what you do. Avoiding these common mistakes is critical for protecting your equipment.

Never Use Tap Water

Tap water contains minerals like calcium and magnesium that rapidly build up inside the autoclave, forming a hard scale. This is the single most common cause of damage. Use only steam-distilled water.

Avoid Abrasive Cleaners and Tools

Never use steel wool, wire brushes, or harsh chemical cleaners (like bleach or scouring powders) inside the chamber. These will scratch the stainless steel surface, creating sites where corrosion can begin.

Do Not Ignore Error Codes

Error codes related to water levels, temperature, or pressure are often the first sign that internal components are clogged or failing due to a lack of proper cleaning. Treat these as urgent alerts requiring immediate attention.

Making the Right Choice for Your Goal

Implementing a consistent protocol ensures that this critical task is never overlooked.

- If your primary focus is patient safety and compliance: Adhere strictly to the daily, weekly, and monthly schedule without fail, and maintain a detailed cleaning log as part of your infection control documentation.

- If your primary focus is extending equipment lifespan and minimizing costs: Make the exclusive use of distilled water a non-negotiable rule in your practice and always use manufacturer-approved cleaning agents.

- If your primary focus is operational efficiency: Ensure all staff members are trained on these procedures to guarantee consistency and prevent failed sterilization cycles that can disrupt patient flow.

A properly maintained autoclave is the silent cornerstone of a safe, compliant, and efficient dental practice.

Summary Table:

| Task Frequency | Key Actions | Primary Goal |

|---|---|---|

| Daily | Wipe door, gasket, and chamber with distilled water. | Remove daily debris and ensure a proper seal. |

| Weekly | Drain and refill reservoir; clean chamber and trays. | Prevent buildup of contaminants and biofilm. |

| Monthly | Run a cleaning cycle with a specialized solution. | Remove internal mineral deposits and scale. |

Ensure your practice's safety and compliance with the right equipment. Proper maintenance starts with a reliable autoclave. KINTEK specializes in high-performance lab equipment and consumables, including dental autoclaves and approved cleaning solutions, to meet your laboratory's exacting standards.

Contact us today for expert guidance on selecting and maintaining the autoclave that best fits your practice's needs, and discover how we can support your commitment to patient safety.

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- How does an autoclave work in simple words? Sterilize with High-Pressure Steam

- What is the use of autoclave in microbiology? Ensuring Sterile Conditions for Reliable Results

- What are the limitations and disadvantages of autoclaves? Ensure Sterilization Success by Avoiding Common Pitfalls

- What is a potential risk of using an autoclave? Avoid Costly Material Damage in Your Lab

- What are the two types of autoclave used in the laboratory? Gravity vs. Pre-Vacuum Explained

- What are the maintenance procedures for autoclave? Ensure Sterilization Safety and Reliability

- How long does a typical autoclave run? Understand the Full Cycle for Safe Sterilization

- What kind of hazard can a lab personnel experienced in working with autoclave? Avoid Complacency with These Critical Risks