At its core, designing a bioreactor is an exercise in applied biology. You must first deeply understand the needs of the cells or microorganisms you wish to cultivate. Only then can you engineer a physical vessel and control system that creates the perfect environment for them to thrive and generate your desired product.

The most common mistake in bioreactor design is focusing on the hardware first. The optimal design always flows from the biology outward—matching the vessel's physical characteristics and control capabilities to the precise metabolic and shear-sensitivity requirements of your specific cell line.

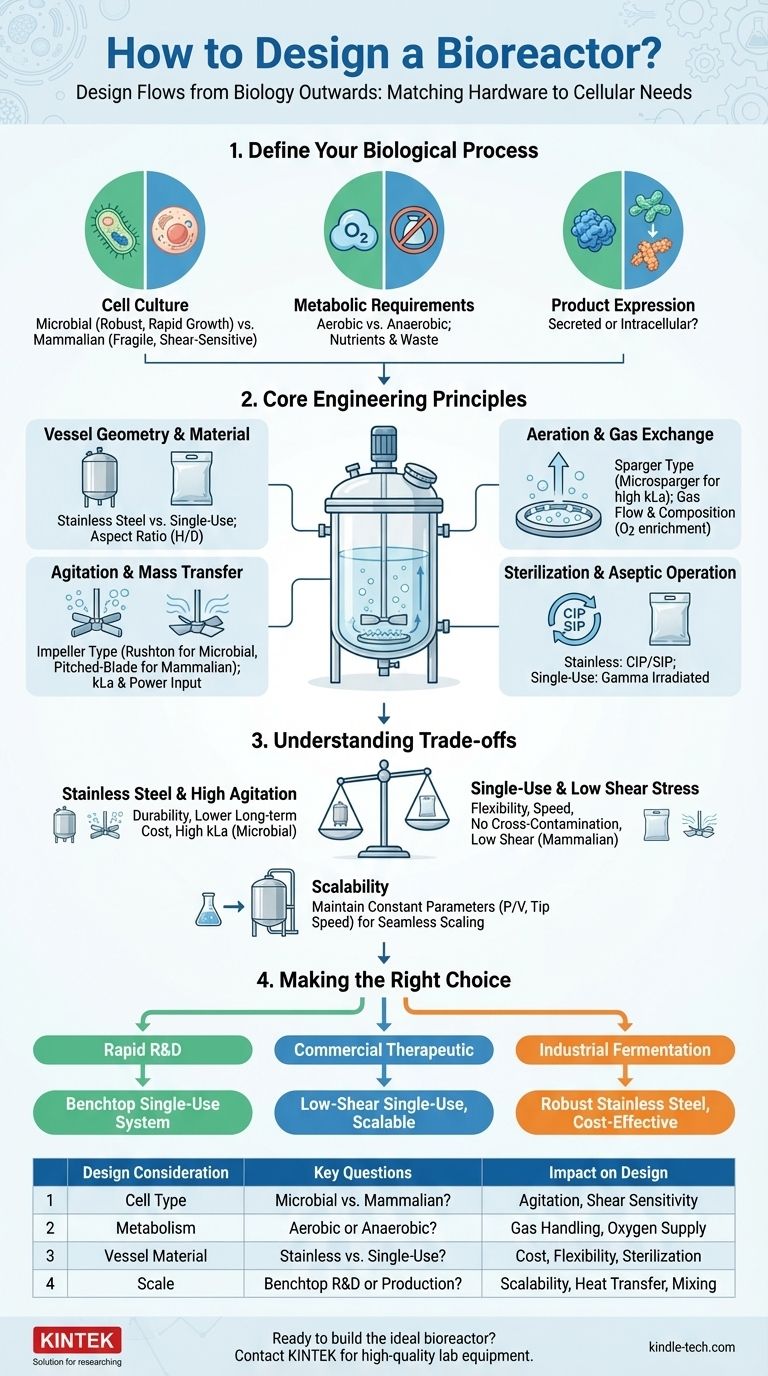

The Foundation: Define Your Biological Process

Before a single screw is turned, the entire design is dictated by the living organism at the center of the process. Your primary task is to define its needs.

Characterize the Cell Culture

The type of cell is the single most important factor. Is it a robust microbial culture like bacteria or yeast, or a fragile and sensitive mammalian cell line?

Microbial cells (e.g., E. coli, S. cerevisiae) can often withstand high agitation and have rapid growth rates, demanding high oxygen transfer and efficient heat removal.

Mammalian cells (e.g., CHO cells) are much larger, lack a cell wall, and are highly sensitive to shear stress. They require gentle mixing and a more precisely controlled environment.

Understand Metabolic Requirements

You must quantify what your cells consume and what they produce. Key questions include:

- Aerobic or Anaerobic? This determines the entire gas handling strategy. Aerobic processes need an efficient oxygen supply, while anaerobic ones must exclude it.

- What are the key nutrients? This dictates the formulation of the culture medium and the feeding strategy (batch, fed-batch, or perfusion).

- What waste products accumulate? Byproducts like lactate or ammonia can become toxic and inhibit growth, requiring careful monitoring and control.

Clarify Product Expression

Where is your target product? Is it secreted into the culture medium, making it easier to harvest?

Or is it an intracellular product, which means the cells must be harvested and lysed (broken open) to recover it? This decision fundamentally impacts the downstream processing steps.

Core Engineering Principles

Once the biological needs are defined, you can translate them into engineering specifications for the reactor system.

Vessel Geometry and Material

The vessel itself is the primary container. The two dominant material choices are stainless steel and single-use plastic.

The vessel's aspect ratio (height-to-diameter) influences mixing efficiency and foam formation. A taller, thinner vessel may improve gas transfer but can create mixing zones, while a shorter, wider vessel provides more uniform mixing.

Agitation and Mass Transfer

The goal of agitation is to create a homogenous environment, ensuring cells have uniform access to nutrients and oxygen while preventing thermal gradients.

The impeller (the "propeller") is key. A Rushton turbine is excellent for gas dispersion and high-mass transfer in robust microbial cultures. A pitched-blade or marine-style impeller provides gentler axial flow, which is critical for shear-sensitive mammalian cells.

The effectiveness of oxygen delivery is measured by the mass transfer coefficient (kLa). Your design must achieve a kLa that meets the cells' Oxygen Uptake Rate (OUR).

Aeration and Gas Exchange

This system delivers oxygen and removes waste CO2. A sparger, typically a ring or porous frit at the bottom of the vessel, releases gas bubbles into the medium.

The size of the bubbles matters. Microspargers create very fine bubbles with high surface area for better oxygen transfer but can also generate more foam. The gas flow rate and composition (e.g., enriching with pure O2) are critical control parameters.

Sterilization and Aseptic Operation

The system must be sterile to prevent contamination. Stainless steel reactors use Clean-in-Place (CIP) and Steam-in-Place (SIP) procedures.

Single-use bioreactors (SUBs) come pre-sterilized by gamma irradiation, eliminating the need for these complex utility steps and guaranteeing sterility out of the box. The entire design must maintain an aseptic boundary.

Understanding the Trade-offs

Every design choice involves a compromise. Understanding these trade-offs is the hallmark of an experienced engineer.

Stainless Steel vs. Single-Use Systems

Stainless steel offers maximum durability and customizability. It represents a high capital expenditure but can have a lower long-term cost per batch for large-scale, dedicated production. However, it requires significant infrastructure for cleaning and sterilization, leading to longer turnaround times.

Single-Use Bioreactors (SUBs) offer unmatched flexibility and speed. They eliminate cleaning validation and drastically reduce the risk of cross-contamination. This makes them ideal for multi-product facilities and clinical manufacturing, despite a higher cost per batch due to the disposable components.

High Agitation vs. Low Shear Stress

For industrial fermentation, the goal is often to maximize agitation to achieve the highest possible kLa for a dense microbial culture. The hardware is designed for aggressive mixing.

For therapeutic protein production in mammalian cells, this approach is destructive. The design must minimize shear stress. This means using low-shear impellers, optimizing their position, and controlling rotational speed (RPM) precisely, often supplementing oxygen control via gas flow rather than agitation.

Scalability: From Benchtop to Production

A design that works at 2 liters will not automatically work at 2,000 liters. As volume increases, the surface-area-to-volume ratio decreases, making heat removal much more difficult.

To ensure a process is scalable, designers often try to keep certain parameters constant, such as power per unit volume (P/V) or impeller tip speed. This modeling must be considered during the initial design phase to avoid process failure at a larger scale.

Making the Right Choice for Your Goal

Your final design is a direct reflection of your primary objective.

- If your primary focus is rapid research and process development: Choose a flexible, pre-sterilized single-use benchtop system to maximize experimental throughput and minimize turnaround time.

- If your primary focus is producing a commercial therapeutic with mammalian cells: Prioritize a single-use system with low-shear agitation, extensive sensor integration, and a well-documented, scalable design path.

- If your primary focus is large-scale industrial fermentation (e.g., biofuels, enzymes): Design a robust, cost-effective stainless steel reactor optimized for high mass transfer, efficient cooling, and long-term, dedicated production.

A well-designed bioreactor is not just a piece of equipment; it is a precisely engineered ecosystem tailored to the life it contains.

Summary Table:

| Design Consideration | Key Questions | Impact on Design |

|---|---|---|

| Cell Type | Microbial vs. Mammalian? | Agitation intensity, shear sensitivity |

| Metabolism | Aerobic or Anaerobic? | Gas handling strategy, oxygen supply |

| Vessel Material | Stainless Steel vs. Single-Use? | Capital cost, flexibility, sterilization needs |

| Scale | Benchtop R&D or Large-Scale Production? | Scalability, heat transfer, mixing efficiency |

Ready to build the ideal bioreactor for your specific application? The right lab equipment is critical for success. KINTEK specializes in high-quality lab equipment and consumables, serving diverse laboratory needs. Our experts can help you select the perfect bioreactor system to ensure your cells thrive and your process scales efficiently. Contact our team today to discuss your project and discover how we can support your research and production goals!

Visual Guide

Related Products

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Shaking Incubators for Diverse Laboratory Applications

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Laboratory Hybrid Tissue Grinding Mill

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

People Also Ask

- How does a reactor work in the pharmaceutical industry? The Engine for Precise API Synthesis

- Why are Dry Methane Reforming (DMR) reactors designed with high-temperature alloys? Ensuring Thermal Stability

- What advantages does a high-pressure hydrothermal reactor provide for hydroxyapatite synthesis? Boost Catalyst Performance

- What are the functions of a stainless steel autoclave with PTFE liner in glycerol etherification? Maximize Purity & Safety

- How do Rh(III) and silane reduction equipment requirements compare to traditional hydrogenation? Simplify Your Lab Setup

- How do temperature-controlled reaction systems affect pitchblende crystallization? Maximize Uranium Removal Efficiency

- What is the role of a laboratory reactor in the production of modified fly ash microspheres? Precision Surface Coating

- What role does a high-pressure reactor, or autoclave, play in S-CO2 corrosion testing? Unlock Material Durability