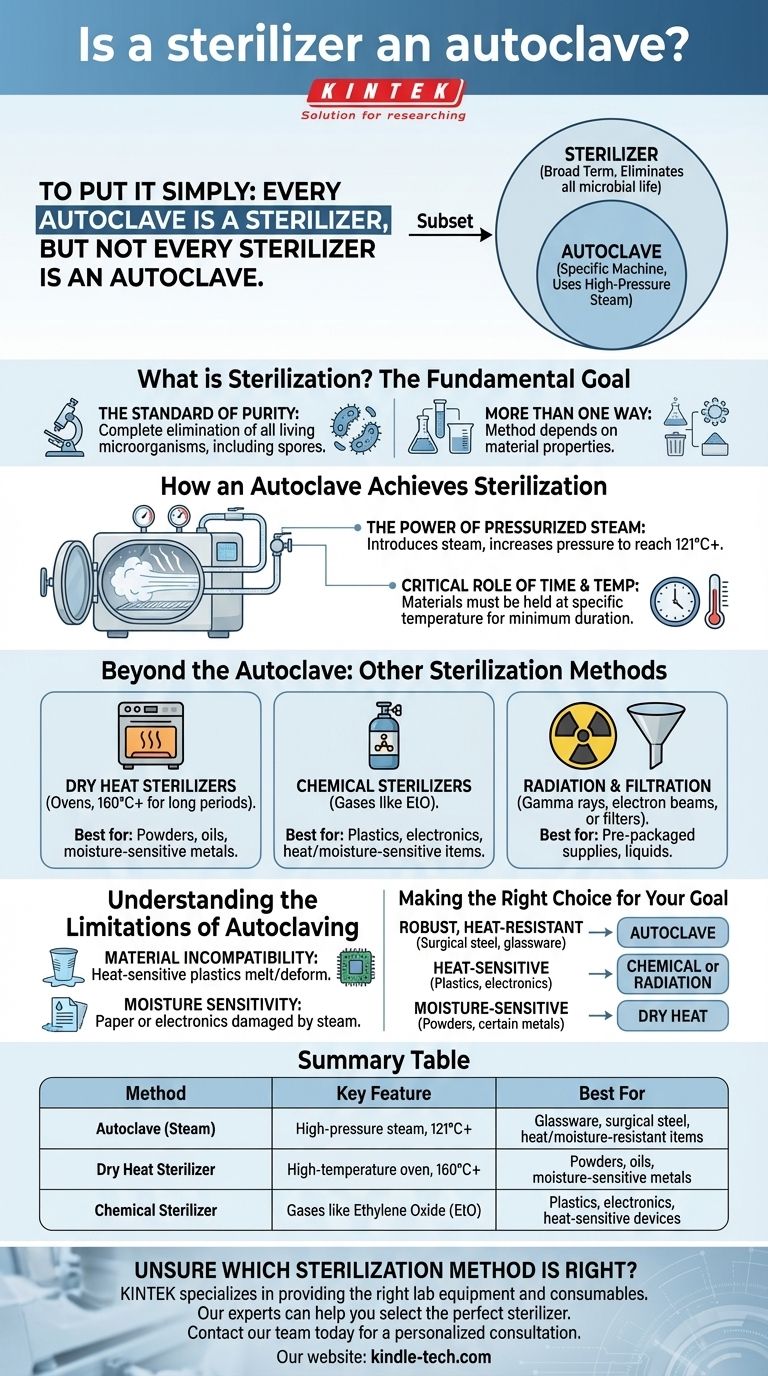

To put it simply, every autoclave is a type of sterilizer, but not every sterilizer is an autoclave. "Sterilizer" is a broad term for any equipment that can eliminate all forms of microbial life, while an "autoclave" is a specific device that achieves this using high-pressure steam.

Sterilization is the process of destroying all microorganisms. An autoclave is a specific machine that performs this process using pressurized steam, making it one of the most common and effective methods, but it is not the only one.

What is Sterilization? The Fundamental Goal

The Standard of Purity

Sterilization is not just cleaning; it is the complete elimination or destruction of all living microorganisms, including resilient bacterial spores. This absolute standard is critical in medical, laboratory, and manufacturing settings to prevent contamination.

More Than One Way to Sterilize

Because different materials react differently to heat, pressure, and chemicals, various sterilization methods have been developed. The method chosen depends entirely on what is being sterilized.

How an Autoclave Achieves Sterilization

The Power of Pressurized Steam

An autoclave is essentially a highly specialized pressure chamber. It works by introducing steam and then increasing the pressure, which allows the steam to reach temperatures far above the normal boiling point of water (typically 121°C or higher).

This high-temperature, moisture-rich environment is extremely effective at denaturing the structural proteins and enzymes within microorganisms, ensuring a complete kill.

The Critical Role of Time and Temperature

For an autoclave cycle to be successful, materials must be held at a specific temperature for a minimum duration. Following the correct protocol for time, temperature, and proper loading is essential for ensuring heat penetrates the entire load and achieves true sterility.

Beyond the Autoclave: Other Sterilization Methods

Dry Heat Sterilizers

These devices are essentially ovens that use high temperatures (160°C or more) over a longer period. They are used for materials that can withstand heat but are sensitive to moisture, such as powders, oils, and certain metal instruments.

Chemical Sterilizers

For items that are sensitive to both heat and moisture, chemical sterilization is the solution. Devices using gases like ethylene oxide (EtO) can effectively sterilize sensitive items like plastics, electronics, and medical implants without damaging them.

Radiation and Filtration

Other common methods include radiation (using gamma rays or electron beams), which is often used for pre-packaged medical supplies, and filtration, which removes microbes from liquids without using heat.

Understanding the Limitations of Autoclaving

Material Incompatibility

The primary limitation of an autoclave is its reliance on high heat and moisture. It cannot be used for all materials.

Heat-sensitive (thermolabile) products, such as many plastics, will melt or deform under standard autoclave conditions.

Moisture Sensitivity

Materials that can be damaged by moisture, such as paper products or sensitive electronics, must be sterilized using alternative methods like dry heat or chemical sterilization. This prevents damage and ensures the integrity of the item.

Making the Right Choice for Your Goal

Selecting the correct sterilization method is not just about effectiveness; it's about protecting the material you are working with.

- If your primary focus is robust, heat-resistant items like surgical steel or laboratory glassware: The autoclave is the most reliable and efficient method.

- If your primary focus is heat-sensitive plastics, electronics, or complex medical devices: You must use a non-autoclave method like chemical (EtO) or radiation sterilization.

- If your primary focus is moisture-sensitive materials like powders or certain metals: A dry heat sterilizer is the appropriate choice.

Matching the method to the material ensures both complete sterility and the integrity of your equipment.

Summary Table:

| Method | Key Feature | Best For |

|---|---|---|

| Autoclave (Steam) | High-pressure steam, 121°C+ | Glassware, surgical steel, heat/moisture-resistant items |

| Dry Heat Sterilizer | High-temperature oven, 160°C+ | Powders, oils, moisture-sensitive metals |

| Chemical Sterilizer | Gases like Ethylene Oxide (EtO) | Plastics, electronics, heat-sensitive devices |

Unsure which sterilization method is right for your specific lab equipment and materials? KINTEK specializes in providing the right lab equipment and consumables for your needs. Our experts can help you select the perfect autoclave or alternative sterilizer to ensure complete sterility while protecting your valuable instruments. Contact our team today for a personalized consultation and enhance your lab's safety and efficiency.

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is the role of a PTFE-lined stainless steel autoclave? Master Gamma-AlOOH Synthesis with High Purity

- Is a retort a pressure vessel? The Critical Safety Classification for Your Sterilization Process

- What is the function of an autoclave in preparing SRB culture media? Ensuring Sterility for Accurate Microbial Data

- What critical functions do zirconia sleeves and gaskets perform in autoclave cracking tests? Ensure Data Precision

- Why is a pressure steam sterilizer necessary for laboratory equipment? Ensure Accuracy in Disinfection Research

- What is the purpose of using a high-pressure hydrothermal autoclave in the synthesis of MXene/ferrite composites?

- Why is an autoclave required for treating biomass hydrolysate? Ensure Sterile Fermentation for High Yields

- What are the advantages of using an autoclave in the lab? Achieve Unmatched Sterilization for Your Lab