No, a UV sterilizer is not as good as an autoclave. These two technologies serve fundamentally different purposes and achieve vastly different levels of microbial elimination. An autoclave is designed for true sterilization, while a device marketed as a "UV sterilizer" actually performs disinfection.

The core distinction is this: an autoclave uses pressurized steam to destroy all forms of microbial life, including highly resistant bacterial spores. A UV device uses light to disinfect surfaces but is easily blocked by shadows and cannot penetrate materials, leaving it incapable of achieving the complete sterility an autoclave provides.

The Critical Difference: Sterilization vs. Disinfection

Understanding the gap between these two terms is essential for any technical or medical application. They are not interchangeable.

What is Sterilization?

Sterilization is an absolute term. It refers to any process that completely eliminates, removes, or destroys all forms of microbial life.

This includes active bacteria, viruses, fungi, and their dormant, highly-resistant forms known as spores. An item is either sterile or it is not.

What is Disinfection?

Disinfection is the process of eliminating many or all pathogenic microorganisms on an object, except for bacterial spores.

While disinfection significantly reduces the risk of infection, it does not guarantee that an object is free from all viable microbes.

How an Autoclave Achieves True Sterilization

An autoclave operates on a principle of overwhelming force, using a combination of three factors to ensure complete microbial destruction.

Mechanism: Steam, Heat, and Pressure

An autoclave is essentially a highly specialized pressure chamber. It uses high-pressure steam to reach and maintain temperatures (typically 121°C or higher) that are impossible to achieve at normal atmospheric pressure.

This combination of intense heat and moisture, driven by pressure, denatures the structural proteins and enzymes of all microorganisms, killing them effectively.

Verification: Proving Complete Kill

The effectiveness of an autoclave is not assumed; it is rigorously proven. Its performance is monitored using biological indicators, often containing the spores of Geobacillus stearothermophilus.

These spores are exceptionally resistant to heat. If the autoclave process is sufficient to kill them, it is considered successful and the load is confirmed as sterile.

How a UV "Sterilizer" Achieves Disinfection

UV devices, more accurately called UV sanitizers or disinfectors, operate on a completely different principle that comes with significant limitations.

Mechanism: UV-C Light Radiation

These devices use short-wavelength ultraviolet light (UV-C) to damage the DNA and RNA of microorganisms.

This genetic damage renders the microbes incapable of reproducing, effectively inactivating them.

The Impact of Wavelength

The effectiveness is highly dependent on the specific UV wavelength, the intensity of the light source, and the duration of exposure.

Understanding the Practical Limitations

The choice between these two methods becomes clear when you examine their real-world limitations. One is a robust, penetrating process, while the other is a fragile, surface-level treatment.

Limitation 1: Line-of-Sight and Shadows

UV radiation can only inactivate microbes that it directly strikes. It cannot bend around corners or penetrate into crevices.

Any "shadow" cast by the shape of the object itself, a spec of dust, or organic material will completely protect microbes from the UV light, leaving them viable.

Limitation 2: Lack of Penetration

UV light has virtually no ability to penetrate materials. It cannot sterilize liquids in opaque containers, items inside a pouch, or the internal components of a complex device.

An autoclave's pressurized steam, by contrast, actively penetrates porous materials and reaches every surface of a properly loaded complex instrument, ensuring sterility inside and out.

Making the Right Choice for Your Application

Your goal determines the required level of microbial elimination. One process is for critical applications, while the other is for low-risk surface decontamination.

- If your primary focus is sterility for medical instruments, lab equipment, or growth media: The autoclave is the only acceptable choice. Its ability to kill spores and penetrate materials is non-negotiable for these critical tasks.

- If your primary focus is reducing the microbial load on a smooth, flat surface: A UV-C device can be a useful tool for supplemental disinfection, such as for a biosafety cabinet surface or sanitizing goggles after cleaning.

Ultimately, relying on a UV device for a task that requires true sterility is a significant operational failure and a potential safety risk.

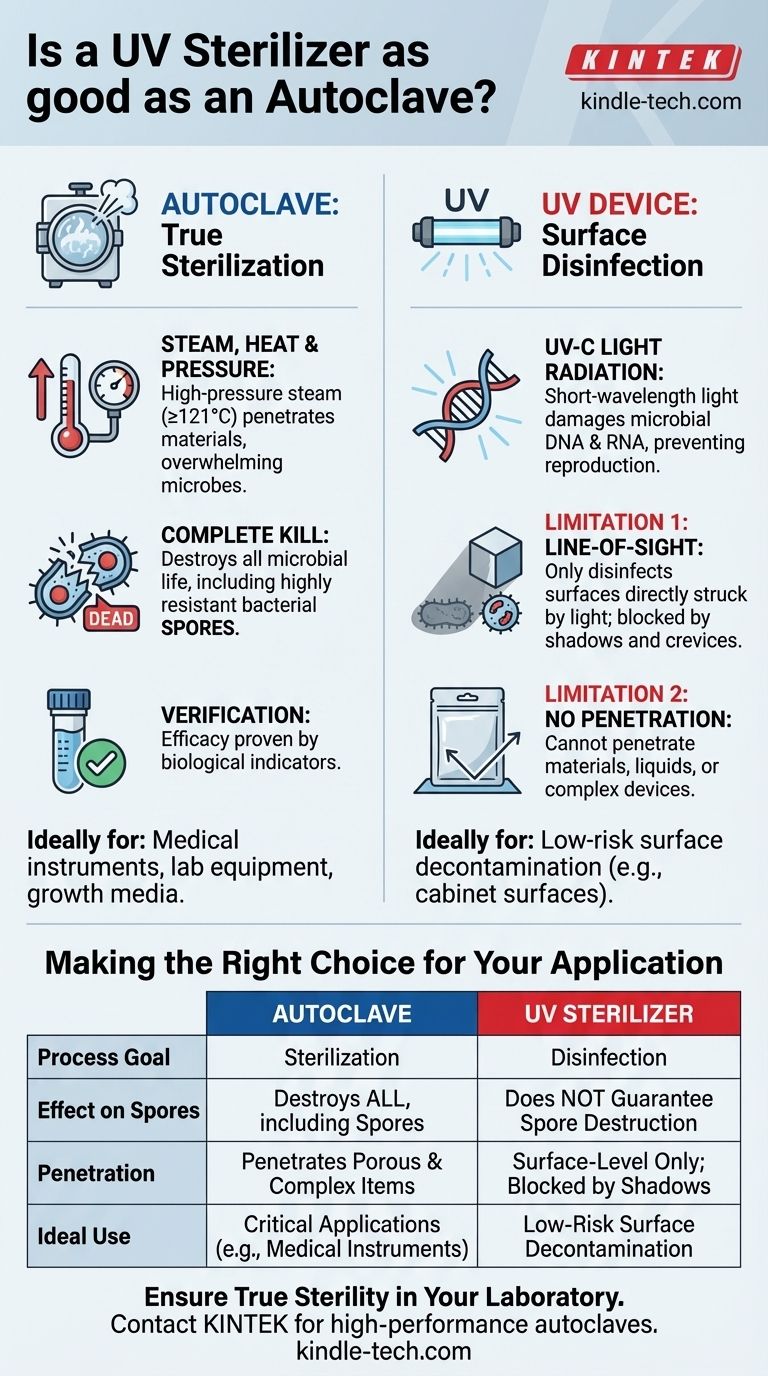

Summary Table:

| Feature | Autoclave | UV Sterilizer |

|---|---|---|

| Process Goal | Sterilization | Disinfection |

| Effect on Spores | Destroys all microbial life, including spores | Does not guarantee spore destruction |

| Penetration | Penetrates porous materials and complex items | Surface-level only; blocked by shadows |

| Ideal Use | Medical instruments, lab equipment, growth media | Low-risk surface decontamination (e.g., cabinet surfaces) |

Ensure True Sterility in Your Laboratory

Choosing the right equipment is critical for safety and compliance. KINTEK specializes in high-performance autoclaves and lab equipment designed to meet the rigorous sterilization demands of research, healthcare, and industrial laboratories.

Our experts can help you select the perfect autoclave to guarantee complete microbial destruction for your instruments and media.

Contact KINTEK today for a consultation and ensure your lab achieves the highest standards of sterility.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- What does autoclaving do to bacteria? It Destroys Them with High-Temperature Steam and Pressure

- What role does an autoclave play in remediation experiments? Ensure Precision by Eliminating Biological Noise

- What are the specifications of a laboratory autoclave? A Guide to Key Features for Safe Sterilization

- What are the different sterilization methods for a microbiology lab? Ensure Reliable and Safe Experiments

- What are the different types of autoclaves in hospitals? Choose the Right Sterilization for Your Needs

- What is the temperature effective for sterilization using autoclave? Achieve Sterile Conditions for Your Lab

- Why is a laboratory high-pressure autoclave sterilizer necessary? Ensure Accuracy in Antibacterial Research

- What is the most common machine used to sterilize medical supplies? The Definitive Guide to Autoclaves