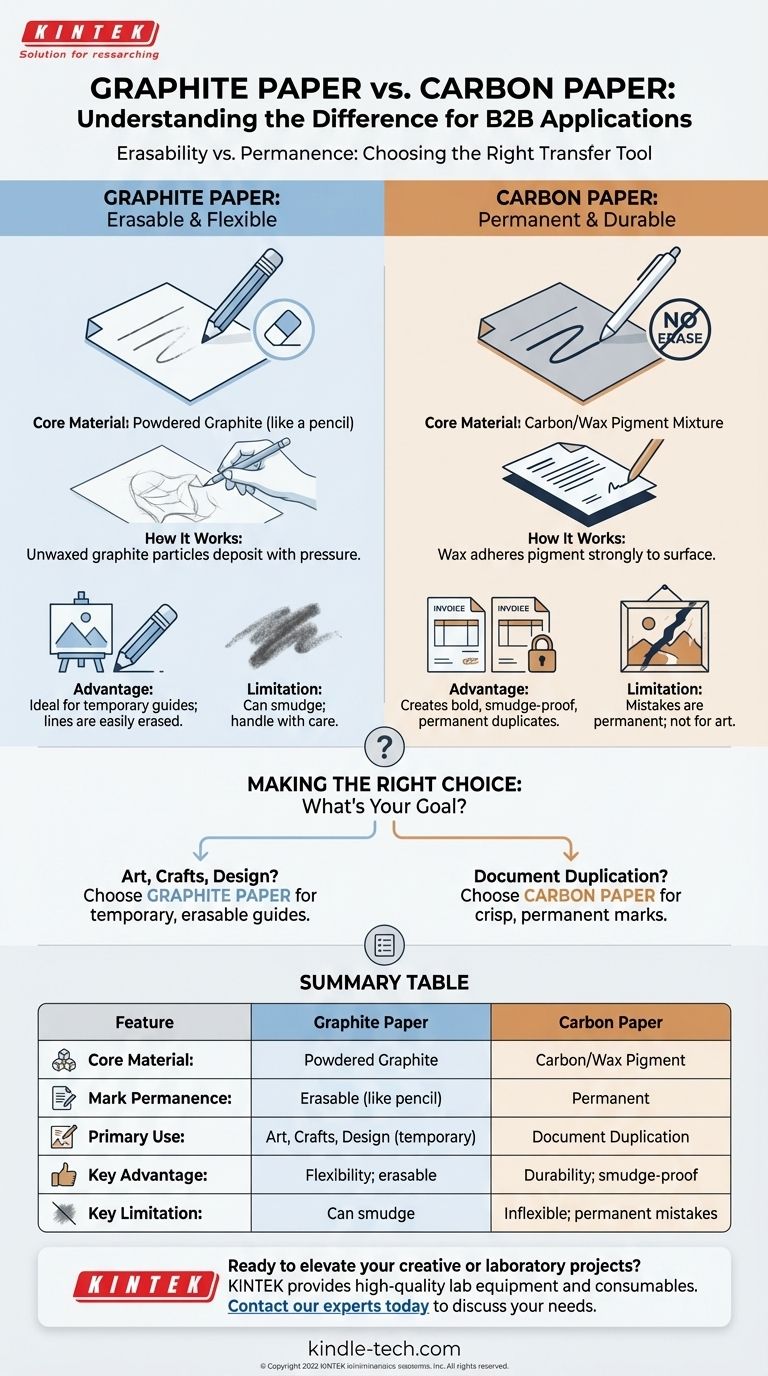

No, graphite paper is not the same as carbon paper. While they serve a similar function of transferring a design from one surface to another, their core materials and intended uses are fundamentally different. Carbon paper creates a permanent mark, whereas graphite paper creates an erasable one, making it the preferred choice for artists and designers.

The critical distinction lies in permanence. Your choice between graphite and carbon paper depends entirely on whether you need a temporary, erasable guide for creative work or a permanent, durable copy for administrative tasks.

The Core Distinction: Erasability vs. Permanence

The primary difference between these two transfer papers comes down to the coating applied to the sheet. This coating dictates how the transferred line behaves on the final surface.

How Graphite Paper Works

Graphite paper is coated with powdered graphite, the same material found in a standard pencil.

It is typically unwaxed, meaning the graphite particles are simply deposited onto the new surface when pressure is applied. This creates a line that is essentially a pencil mark, which can be easily erased.

How Carbon Paper Works

Carbon paper is coated with a mixture of dry ink or carbon black pigment held together with wax.

The wax binder causes the pigment to adhere strongly to the new surface. This process creates a dark, crisp line that is smudge-resistant but also permanent and extremely difficult to erase.

Understanding the Trade-offs

Choosing the wrong paper can have significant consequences for your project. Understanding their specific strengths and weaknesses is essential for avoiding frustration.

The Advantage of Graphite Paper: Flexibility

The erasable nature of graphite paper makes it an ideal tool for artists, illustrators, and woodworkers.

It allows you to transfer a complex design or sketch onto a canvas, watercolor paper, or piece of wood as a preliminary guide. These guide lines can then be painted or inked over and erased later without a trace.

The Limitation of Graphite Paper: Smudging

Because the transferred line is essentially powdered graphite, it can smudge if you drag your hand across it, much like a soft pencil drawing. Care must be taken to keep the final surface clean during your work.

The Advantage of Carbon Paper: Durability

The permanence of carbon paper is its greatest strength. It was designed for creating duplicates of documents, such as invoices or receipts, where a lasting and unalterable copy is required. The lines are bold and do not fade or smudge.

The Limitation of Carbon Paper: Inflexibility

For any creative application, the permanence of carbon paper is a significant drawback. A mistake in tracing is permanent. The dark, waxy lines will often show through layers of paint and cannot be removed, potentially ruining a final piece of art.

Making the Right Choice for Your Project

Selecting the correct paper is a simple decision once you define your goal.

- If your primary focus is creating art, crafts, or designs: Choose graphite paper for its erasable, non-permanent transfer lines that serve as a temporary guide.

- If your primary focus is creating permanent duplicates of documents: Choose carbon paper for its crisp, durable, and smudge-proof marks.

Understanding this fundamental difference ensures you always select the right tool for the task at hand.

Summary Table:

| Feature | Graphite Paper | Carbon Paper |

|---|---|---|

| Core Material | Powdered Graphite | Carbon/Wax Pigment |

| Mark Permanence | Erasable (like pencil) | Permanent |

| Primary Use | Art, Crafts, Design (temporary guide) | Document Duplication |

| Key Advantage | Flexibility; lines can be erased | Durability; smudge-proof marks |

| Key Limitation | Can smudge if not handled carefully | Inflexible; mistakes are permanent |

Ready to elevate your creative or laboratory projects with the right materials?

At KINTEK, we specialize in providing high-quality lab equipment and consumables, including precision materials for artists, designers, and researchers. Whether you're working on intricate designs or need reliable supplies for your laboratory, we have the solutions to support your success.

Contact our experts today to discuss your specific needs and discover how KINTEK can help you achieve superior results with the right tools for the job.

Visual Guide

Related Products

- Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- How is carbon paper constructed? The Engineered Porous Scaffold for High-Performance Applications

- What are the major components of biomass? Unlocking the Building Blocks of Renewable Energy

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use

- How is carbon paper treated for use in fuel cells? The Critical PTFE Coating for Peak Performance

- How can the lifespan of carbon paper be extended? Reinforce Edges with Epoxy for Maximum Durability