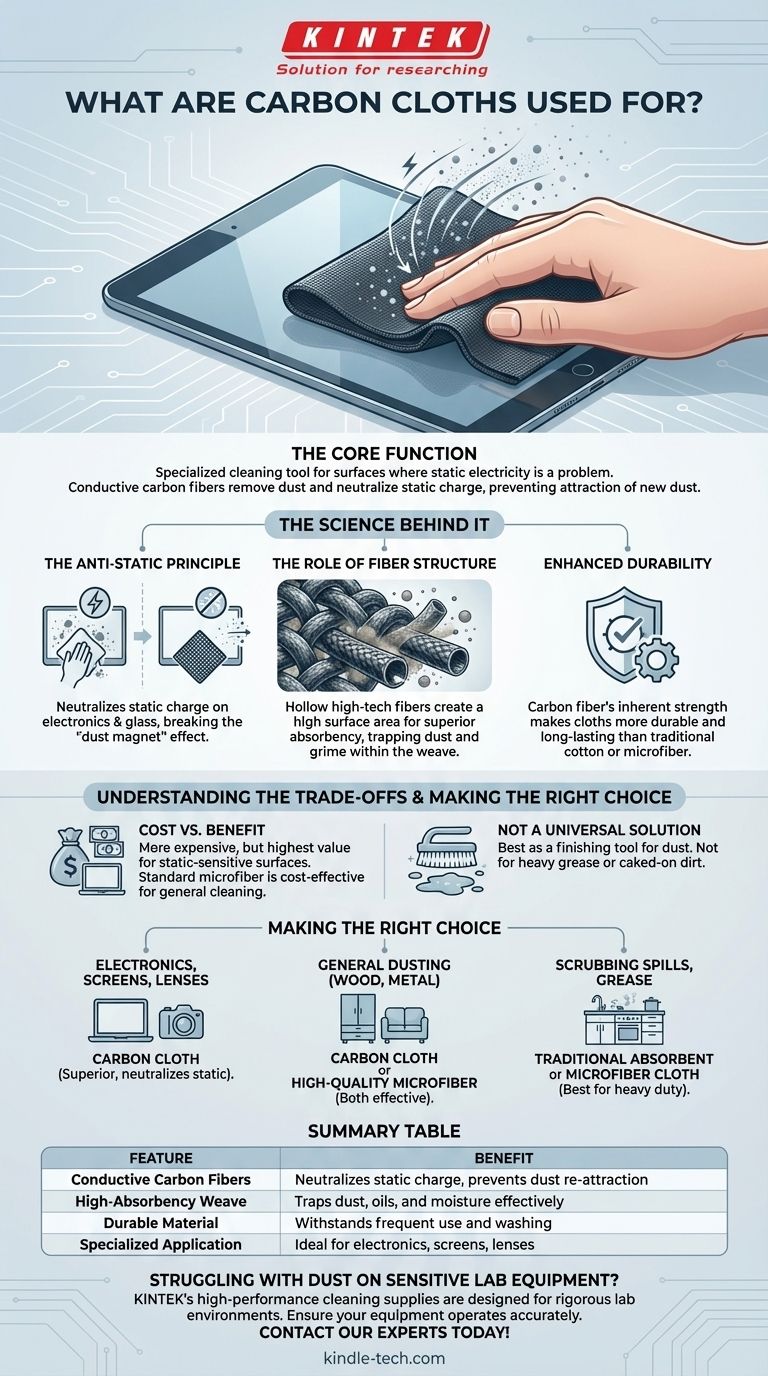

At its core, a carbon cloth is a specialized cleaning tool designed for surfaces where static electricity is a problem. It leverages the conductive properties of carbon fibers to not only remove existing dust but also to neutralize the static charge that attracts new dust, making it particularly effective for electronics, screens, and glass.

Unlike traditional cloths that simply wipe away dust, carbon cloths address the root cause of dust accumulation on many surfaces: static electricity. This makes them a superior tool for cleaning electronics and other static-prone items, ensuring they stay cleaner for longer.

The Science Behind Carbon Cloths

To understand why a carbon cloth is effective, it's important to look beyond simple wiping and consider the physics at play on the surfaces you clean.

The Anti-Static Principle

Many modern surfaces, especially electronics and glass, build up a static electric charge. This charge acts like a magnet for airborne dust particles.

A standard cloth wipes these particles away, but the static charge remains. Dust is then immediately re-attracted to the surface.

Carbon is a naturally conductive material. When the carbon fibers in the cloth touch the surface, they safely neutralize this static charge, breaking the magnetic attraction and preventing dust from immediately resettling.

The Role of Fiber Structure

The reference to carbon as a "hollow high tech fibre" points to its structural advantage in absorption.

Much like high-quality microfiber, the structure of the fibers in a carbon cloth is engineered to have a very high surface area.

This structure creates a capillary effect, allowing the cloth to be highly absorbent and effectively trap dust, oils, and moisture within the weave rather than just pushing them around.

Enhanced Durability

Carbon fiber is renowned for its strength and resilience. This inherent toughness means carbon cleaning cloths are often more durable and longer-lasting than their traditional cotton or low-quality microfiber counterparts, withstanding more frequent use and washing.

Understanding the Trade-offs

While effective, carbon cloths are a specialized tool. Understanding their limitations is key to using them correctly.

Cost vs. Benefit

Carbon cloths are typically more expensive than standard microfiber cloths. Their value is most apparent when used for their specific purpose: eliminating static on sensitive surfaces.

For general-purpose cleaning, such as wiping down a kitchen counter, a standard microfiber cloth is often a more cost-effective choice.

Not a Universal Solution

The primary advantage of a carbon cloth is its anti-static property. It will not perform significantly better than a dedicated cleaning cloth for removing heavy grease, grime, or caked-on dirt.

Think of it as a finishing tool for dust-prone surfaces, not an all-purpose scrubber.

Making the Right Choice for Your Task

Use the nature of your cleaning challenge to guide your choice of tool.

- If your primary focus is cleaning electronics, screens, or camera lenses: A carbon cloth is the superior choice because it neutralizes the static that attracts dust.

- If your primary focus is general household dusting on wood or metal: A carbon cloth is very effective and durable, but a high-quality microfiber cloth will also perform well.

- If your primary focus is scrubbing spills or greasy surfaces: Stick with a traditional absorbent or microfiber cloth specifically designed for that cleaning challenge.

Ultimately, choosing the right cleaning tool is about matching the material's unique properties to the specific problem you need to solve.

Summary Table:

| Feature | Benefit |

|---|---|

| Conductive Carbon Fibers | Neutralizes static charge to prevent dust from re-attracting |

| High-Absorbency Weave | Traps dust, oils, and moisture effectively |

| Durable Material | Withstands frequent use and washing for long-term value |

| Specialized Application | Ideal for electronics, screens, lenses, and other static-prone surfaces |

Struggling with dust on sensitive lab equipment? Static buildup can interfere with precision instruments and experiments. KINTEK's high-performance cleaning supplies, including specialized cloths, are designed to meet the rigorous demands of laboratory environments. Ensure your equipment stays dust-free and operates accurately. Contact our experts today to find the perfect cleaning solution for your lab's needs!

Visual Guide

Related Products

- Isostatic Molding Pressing Molds for Lab

- Aluminum Foil Current Collector for Lithium Battery

- Lab Sterile Slapping Type Homogenizer for Tissue Mashing and Dispersing

- Lab Infrared Press Mold

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

People Also Ask

- What is the function of high-strength pressure molds for nanostructured copper powders? Achieve High Purity Densification

- How do steel molds and hydraulic equipment collaborate for high-density molding? Optimize WC/Cu FGM Green Body Prep

- What are molds used for? Unlock Mass Production of Precision Parts

- Why is a Cold Isostatic Press (CIP) Required for NaSICON? Achieve Maximum Green Density and Ionic Conductivity

- How does a Hot Isostatic Press (HIP) machine improve AlFeTiCrZnCu alloys? Achieving 10 GPa Hardness and Maximum Density