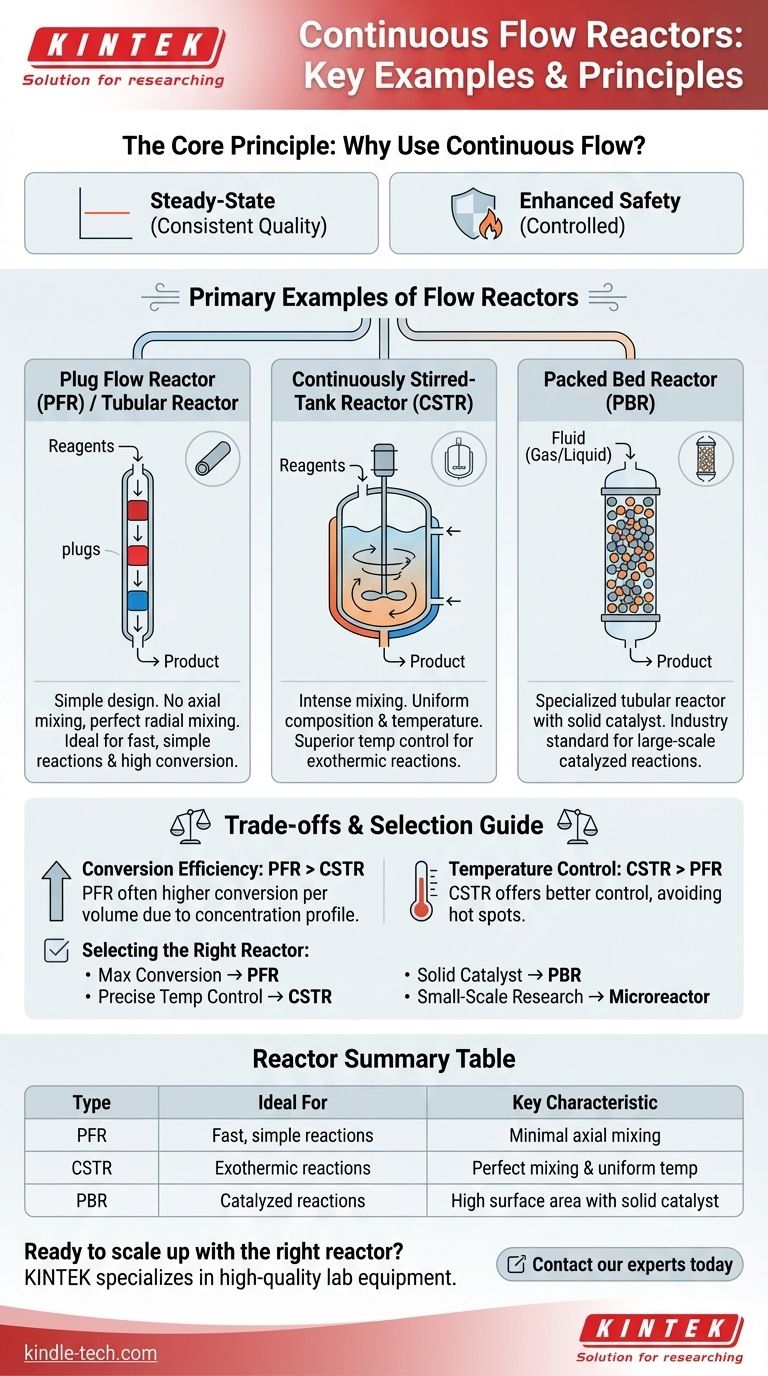

In practice, the most common examples of continuous flow reactors are the Plug Flow Reactor (PFR), often realized as a simple tubular reactor, the Continuously Stirred-Tank Reactor (CSTR), and the Packed Bed Reactor (PBR) for reactions involving solid catalysts. Each design offers a distinct environment for a chemical reaction, chosen specifically to optimize reaction speed, product purity, and safety.

The specific type of continuous flow reactor chosen is not an arbitrary decision. It is a deliberate engineering choice determined by the reaction's fundamental requirements, such as the phases involved (gas, liquid, solid), heat transfer demands, and the desired mixing profile.

The Core Principle: Why Use Continuous Flow?

Before examining specific reactor types, it's essential to understand why continuous flow processing is chosen over traditional batch processing, where all ingredients are mixed in a single vessel at the start.

The Advantage of Steady-State

Continuous flow reactors operate at a steady-state, meaning process conditions like temperature, pressure, and concentration at any given point within the reactor remain constant over time.

This stability leads to highly consistent product quality and predictable performance, which is difficult to achieve in a batch reactor where conditions are constantly changing.

Enhanced Safety and Control

By design, flow reactors contain a much smaller volume of reactive material at any moment compared to a large batch vessel.

This miniaturization of the reaction zone dramatically improves safety, especially for highly energetic (exothermic) or hazardous reactions. Heat generated can be removed far more efficiently, preventing dangerous temperature spikes and runaway reactions.

Key Types of Continuous Flow Reactors

The primary examples of flow reactors are distinguished by their mixing characteristics and physical form.

Plug Flow Reactors (PFR) / Tubular Reactors

A Plug Flow Reactor is the simplest model, often visualized as a long pipe or tube. Reagents are continuously pumped into one end, and the product emerges from the other.

In an ideal PFR, there is no axial mixing (mixing along the length of the tube), but perfect radial mixing (mixing across the tube's diameter). Each "plug" of fluid moves through the reactor without interacting with the plugs in front of or behind it, experiencing the full reaction journey from start to finish.

These are ideal for simple, fast, and well-behaved reactions, particularly in single-phase systems (liquid-liquid or gas-gas).

Continuously Stirred-Tank Reactors (CSTR)

A CSTR is a vessel equipped with an impeller (a mixer) that is continuously fed with reactants and from which the product mixture is continuously removed.

The key feature of a CSTR is its intense mixing. The goal is to create a perfectly uniform composition and temperature throughout the entire reactor. This means the concentration of the product exiting the reactor is identical to the concentration inside the reactor.

CSTRs excel at temperature control due to the large heat transfer area and high mixing. They are often used for reactions where precise temperature is critical or when reactants need to be kept dilute. For high conversion, multiple CSTRs are often connected in series.

Packed Bed Reactors (PBR)

A Packed Bed Reactor is a specialized type of tubular reactor that is filled with solid particles, most commonly a heterogeneous catalyst.

The fluid (gas or liquid) flows through the void spaces between the stationary solid particles. This design is the industry standard for large-scale catalyzed reactions, such as ammonia synthesis or petroleum refining.

The solid packing provides an enormous surface area for the reaction to occur, but it can also create challenges with pressure drop and heat distribution.

Understanding the Trade-offs: CSTR vs. PFR

Choosing between the two most common reactor models involves clear engineering trade-offs.

Conversion Efficiency

For most standard reactions, a PFR is more efficient than a CSTR of the same volume. Because reactants are at their highest concentration at the inlet of a PFR, the reaction rate is initially very high. In a CSTR, incoming reactants are immediately diluted to the low concentration of the outlet, slowing the overall reaction rate.

Temperature Control

A CSTR offers superior temperature control. The constant, vigorous mixing distributes heat evenly, preventing hot spots that can degrade products or cause safety issues. A PFR can develop significant temperature gradients along its length, which requires more complex jacketing or cooling designs to manage.

Handling Solids and Viscosity

CSTRs are generally better at handling slurries or reactions that produce solid precipitates, as the intense mixing can keep the solids suspended. A PFR or PBR can easily become clogged by solids.

Selecting the Right Reactor for Your Process

Your choice of reactor should be guided by the specific goals of your chemical process.

- If your primary focus is maximizing conversion for a simple reaction: A Plug Flow Reactor (PFR) is typically the most volume-efficient choice.

- If your primary focus is precise temperature control for an exothermic reaction: A Continuously Stirred-Tank Reactor (CSTR) provides the most stable thermal environment.

- If your primary focus is running a reaction with a solid catalyst: A Packed Bed Reactor (PBR) is the purpose-built and industry-standard solution.

- If your primary focus is small-scale research with excellent control: A microreactor, which acts like a highly efficient PFR, offers unparalleled heat/mass transfer and safety.

Ultimately, the reactor is not just a container; it is an engineered tool designed to create the ideal environment for a specific chemical transformation.

Summary Table:

| Reactor Type | Ideal For | Key Characteristic |

|---|---|---|

| Plug Flow Reactor (PFR) | Fast, simple reactions; high conversion | Minimal axial mixing; reactants flow like 'plugs' |

| Continuously Stirred-Tank Reactor (CSTR) | Precise temperature control; exothermic reactions | Perfect mixing; uniform composition & temperature |

| Packed Bed Reactor (PBR) | Reactions with solid catalysts (e.g., refining) | Filled with catalyst pellets; high surface area |

Ready to scale up your chemical synthesis with the right reactor?

KINTEK specializes in providing high-quality lab equipment and consumables for laboratory research and development. Whether you are optimizing a catalytic process requiring a PBR or developing a new synthesis needing the precise control of a CSTR, our expertise can help you select the ideal equipment for superior results, enhanced safety, and consistent product quality.

Contact our experts today to discuss your specific application and find the perfect solution for your lab.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

People Also Ask

- What roles do autoclaves play in MFI zeolite synthesis? Master Hydrothermal Crystalline Growth

- What is the purpose of using a high-temperature hydrothermal reactor? Enhance Iodine@Activated Carbon Cathode Synthesis

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation

- Why are high-pressure autoclaves essential for preparing bio-based polyamide curing agents from dimeric acid?

- Why are sealed laboratory reaction vessels necessary in the hydrothermal synthesis of zeolites? Ensure Purity and Yield