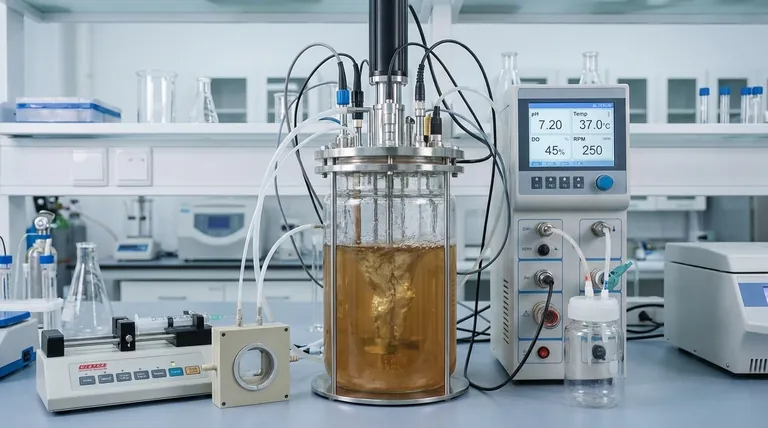

Effective bioreactor control hinges on monitoring a core set of parameters. At a minimum, you must track the critical physical and chemical variables that define the cellular environment: pH, temperature, dissolved oxygen (DO), and agitation speed. These form the foundation of any successful bioprocess, directly influencing cell growth, metabolic activity, and product formation.

Monitoring a bioreactor is not simply about collecting data; it is about maintaining a precise, dynamic equilibrium for your cell culture. Each parameter is interconnected, and mastering this interplay is the key to maximizing yield, ensuring product quality, and achieving scalable, repeatable results.

The Pillars of Environmental Control

The most fundamental parameters are those that create a stable and hospitable physical and chemical environment for your cells. These must be kept within a narrow optimal range.

Temperature

Temperature directly governs the rate of all enzymatic reactions within the cell. Even minor deviations can drastically impact metabolic rates and protein stability.

Maintaining a constant, optimal temperature is non-negotiable. Too high, and proteins may denature, leading to cell death. Too low, and cellular metabolism slows dramatically, reducing productivity.

pH

The pH of the culture medium affects nearly every aspect of cell physiology, including enzyme function, protein stability, and the transport of nutrients across the cell membrane.

Cellular metabolism naturally produces acidic (e.g., lactate) or basic (e.g., ammonia) byproducts, causing the pH to drift. Active control, typically through the automated addition of an acid or base, is essential to counteract this drift and maintain stability.

Agitation (Mixing)

Agitation serves two primary functions: it ensures the culture is homogenous and it enhances the transfer of oxygen from gas bubbles into the liquid medium.

Without proper mixing, gradients in pH, temperature, and nutrient concentration can form, leading to inconsistent cell performance. Agitation breaks up these gradients and ensures all cells experience a uniform environment.

Managing the Gas and Liquid Phases

Cells consume gases (like oxygen) and release others (like carbon dioxide). Managing this exchange is critical, especially for aerobic cultures.

Dissolved Oxygen (DO)

For aerobic organisms, oxygen is a critical substrate. The DO level represents the balance between the rate of oxygen supplied to the culture (via sparging) and the rate at which cells consume it.

If DO drops too low, cells can enter an anaerobic state, leading to the production of inhibitory metabolites and reduced growth. This parameter is so critical it is often used to control other variables, such as agitation speed or gas flow, in a feedback loop.

Gas Flow and Composition

The rate and composition of the gas being sparged into the bioreactor directly control oxygen availability and CO2 removal. This is your primary tool for manipulating the DO level.

Advanced processes also utilize off-gas analysis, measuring the O2 and CO2 in the exhaust stream. This provides a powerful, non-invasive window into the culture's real-time metabolic activity, allowing for calculation of the Oxygen Uptake Rate (OUR) and Carbon Dioxide Evolution Rate (CER).

Pressure

Headspace pressure is often monitored and controlled to enhance the solubility of gases like oxygen (in accordance with Henry's Law) and to maintain the sterility of the system by preventing the ingress of outside contaminants.

Tracking Biological Performance

While environmental parameters tell you about the culture's conditions, biological and metabolic parameters tell you about the culture's response.

Cell Density and Viability

This is the direct measurement of how much biomass you have. It can be measured indirectly via Optical Density (OD) for a quick assessment or directly via offline cell counting to determine the Viable Cell Density (VCD) and viability percentage.

Substrates (e.g., Glucose)

Monitoring the concentration of key nutrients, like the primary carbon source (e.g., glucose), is crucial. This ensures the cells do not become limited by a lack of food, which would halt growth and productivity. This is especially important for designing and controlling fed-batch processes.

Metabolites (e.g., Lactate, Ammonia)

Cells produce waste products as a part of their metabolism. Key metabolites like lactate and ammonia can become toxic at high concentrations, inhibiting growth and even triggering cell death. Monitoring their accumulation is key to understanding the metabolic health of the culture.

Understanding the Trade-offs

Optimizing a bioprocess is a game of balancing competing factors. Monitoring helps you navigate these necessary compromises.

Agitation vs. Shear Stress

Increasing agitation improves oxygen transfer and mixing, but excessive agitation creates high shear forces. These mechanical forces can damage or even lyse sensitive cells, particularly in mammalian cell culture. The goal is to find the lowest agitation speed that still meets the oxygen demand.

Oxygen Supply vs. Oxidative Stress

While low DO is a common problem, excessively high DO can also be damaging. High oxygen concentrations can lead to the formation of reactive oxygen species (ROS), causing oxidative stress and cellular damage. The ideal is a "sweet spot" that is high enough to prevent limitation but not so high that it causes toxicity.

Rich Media vs. Byproduct Toxicity

Starting a batch with very high nutrient concentrations can lead to rapid initial growth. However, for many cell types, this can also trigger "overflow metabolism," where cells wastefully convert a primary nutrient (like glucose) into inhibitory byproducts (like lactate) even when oxygen is plentiful. This is a primary reason for the development of fed-batch strategies.

Tailoring Monitoring to Your Process Goal

The specific parameters you prioritize will depend on your objective.

- If your primary focus is process development and characterization: Monitor a comprehensive set of parameters, including off-gas analysis and key metabolites, to build a deep understanding of your process.

- If your primary focus is routine manufacturing (GMP): Prioritize the validated Critical Process Parameters (CPPs) like pH, DO, temperature, and feed rates, with robust control, alarming, and data-logging systems.

- If your primary focus is rapid screening or media optimization: Focus on key performance indicators like final cell density (OD) and product titer, using simpler monitoring strategies for faster throughput.

Ultimately, strategic monitoring transforms your bioreactor from a black box into a predictable and controllable manufacturing system.

Summary Table:

| Parameter Category | Key Parameters | Primary Function |

|---|---|---|

| Environmental Control | Temperature, pH, Agitation | Creates a stable, hospitable physical/chemical environment for cells. |

| Gas & Liquid Phase | Dissolved Oxygen (DO), Gas Flow, Pressure | Manages oxygen supply, CO2 removal, and gas solubility. |

| Biological Performance | Cell Density/Viability, Substrates, Metabolites | Tracks the culture's health, growth, and metabolic response. |

Ready to achieve precise control and maximize yield in your bioprocess?

KINTEK specializes in providing high-quality lab equipment and consumables for all your bioreactor monitoring needs. From reliable pH and DO probes to advanced sensors for off-gas analysis, our solutions help you maintain the critical equilibrium for scalable, repeatable results.

Let our experts help you select the right tools to transform your bioreactor into a predictable manufacturing system. Contact KINTALK today to discuss your specific laboratory requirements!

Visual Guide

Related Products

- Electrolytic Electrochemical Cell Gas Diffusion Liquid Flow Reaction Cell

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- High Performance Laboratory Freeze Dryer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- What are the primary functions of a high-performance electrolytic cell in the eCO2R process? Optimize Your Lab Results

- What role does a two-electrode electrochemical reactor play in TiO2 growth? Achieve Ordered Nanostructures Today

- What is the purpose of the double-layer structure in the H-type electrolytic cell? Achieve Precise Thermal Control

- What is the precaution regarding temperature when using an all-PTFE electrolytic cell? Essential Thermal Safety Tips

- Which parameters must be strictly controlled using an all-PTFE electrolytic cell? Ensure Precision and Safety