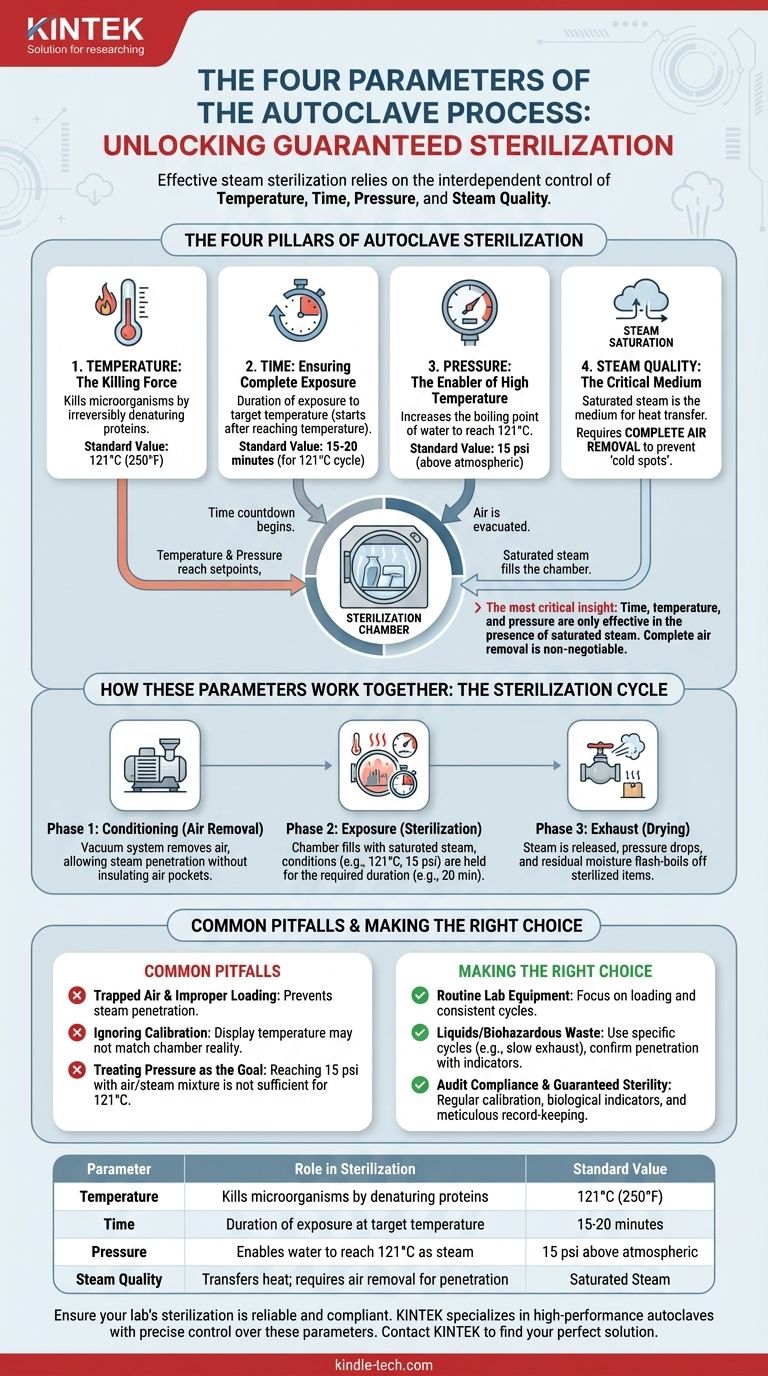

At its core, autoclave sterilization is governed by four interdependent parameters. To achieve effective sterilization, you must control the temperature, the time of exposure, the operating pressure, and the quality of the steam. While often simplified to just time and temperature, the interplay between all four factors is what ensures the complete destruction of all microorganisms.

The most critical insight is that time, temperature, and pressure are only effective in the presence of saturated steam. The complete removal of ambient air from the chamber is the non-negotiable principle that allows moist heat to penetrate and sterilize every surface of the load.

The Four Pillars of Autoclave Sterilization

An autoclave does not sterilize with dry heat or simple pressure; it uses high-temperature steam. Each of the four parameters plays a distinct and essential role in making this process effective.

1. Temperature: The Killing Force

The primary mechanism for killing microorganisms is heat. The standard, scientifically validated temperature for steam sterilization is 121°C (250°F).

This temperature is high enough to irreversibly denature the essential proteins and enzymes within bacteria, viruses, and spores, leading to their death.

2. Time: Ensuring Complete Exposure

The target temperature must be held for a specific duration to ensure complete sterilization. For a standard 121°C cycle, the minimum exposure time is 15 to 20 minutes.

It is crucial to understand that this timer only begins after the chamber has reached the target temperature and pressure, not when the cycle starts.

3. Pressure: The Enabler of High Temperature

Under normal atmospheric conditions, water boils at 100°C (212°F). To reach the required sterilization temperature of 121°C, the pressure inside the autoclave must be increased.

The relationship is a law of physics: by increasing the pressure to approximately 15 pounds per square inch (psi) above atmospheric pressure, the boiling point of water is raised to 121°C. Pressure itself is not the sterilizing agent; it is the condition required to create high-temperature steam.

4. Steam Saturation: The Critical Medium

This is the most frequently misunderstood parameter. Sterilization fails if the heat is not effectively transferred to the items, and saturated steam is the medium for that transfer.

Air is a poor conductor of heat and acts as an insulator. If air is trapped in the chamber, it creates "cold spots" and prevents steam from making direct contact with surfaces. Therefore, the removal of all air and its replacement with saturated steam is fundamental to the process.

How These Parameters Work Together: The Sterilization Cycle

The four parameters are managed across three distinct phases of an autoclave cycle.

Phase 1: Conditioning (Air Removal)

This is the preparatory phase where the chamber is readied for sterilization. A vacuum system removes air from the chamber, allowing steam to enter and penetrate the load without any insulating air pockets.

Phase 2: Exposure (Sterilization)

Once air is evacuated, the chamber is filled with steam, and pressure and temperature rise to the setpoints (e.g., 121°C and 15 psi). The cycle holds these conditions for the predetermined time (e.g., 20 minutes), during which sterilization occurs.

Phase 3: Exhaust (Drying)

After the exposure phase, the steam is released from the chamber, causing the pressure to drop. This sudden depressurization helps flash-boil residual moisture off the sterilized items, allowing them to emerge dry.

Common Pitfalls That Invalidate Sterilization

Achieving the four parameters seems simple, but several common errors can lead to a failed cycle.

Trapped Air and Improper Loading

If items are packed too tightly or wrapped in materials that do not allow for air removal, the conditioning phase will fail. Air will remain trapped, preventing steam from reaching all surfaces and rendering the cycle ineffective, even if the machine's display shows the correct time and temperature.

Ignoring Calibration

The temperature displayed on the control panel may not match the actual temperature inside the chamber. Regular calibration is essential to verify that when the machine is set to 121°C, it is actually achieving 121°C where the items are located.

Treating Pressure as the Goal

Operators sometimes focus on reaching 15 psi without understanding why. If that pressure is reached with a mixture of air and steam, the corresponding temperature will be much lower than 121°C, and sterilization will not occur. True validation comes from monitoring temperature, which is the direct result of pure steam pressure.

Making the Right Choice for Your Sterilization Goal

Your approach to monitoring the autoclave process should depend on your specific needs for safety and compliance.

- If your primary focus is routine sterilization of durable lab equipment: Ensure your cycles consistently run at 121°C and 15 psi for at least 15-20 minutes, and focus on proper loading techniques to allow for steam penetration.

- If your primary focus is sterilizing liquids or biohazardous waste: You must use specific cycles (like slow exhaust for liquids) and confirm penetration with biological or chemical indicators placed in the most challenging part of the load.

- If your primary focus is ensuring audit compliance and guaranteed sterility: Implement a rigorous schedule of regular calibration, routine use of biological indicators, and meticulous record-keeping for every cycle.

Mastering these four parameters transforms the autoclave from a simple machine into a reliable and verifiable tool for guaranteed sterilization.

Summary Table:

| Parameter | Role in Sterilization | Standard Value |

|---|---|---|

| Temperature | Kills microorganisms by denaturing proteins | 121°C (250°F) |

| Time | Duration of exposure at target temperature | 15-20 minutes |

| Pressure | Enables water to reach 121°C as steam | 15 psi above atmospheric |

| Steam Quality | Transfers heat; requires air removal for penetration | Saturated Steam |

Ensure your lab's sterilization is reliable and compliant. KINTEK specializes in high-performance autoclaves and lab equipment, providing the precise control over temperature, time, pressure, and steam quality that your laboratory demands. From routine equipment sterilization to processing sensitive liquids, our solutions deliver guaranteed results. Contact KINTEK today to find the perfect autoclave for your specific needs and achieve peace of mind with every cycle.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What is the life expectancy of an autoclave machine? Maximize Your Investment with Proper Care

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment

- What is the normal temperature of an autoclave? Achieve Sterile Confidence with Precise Control

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- What types of items and materials can be processed in a laboratory autoclave? Essential Guide for Lab Safety