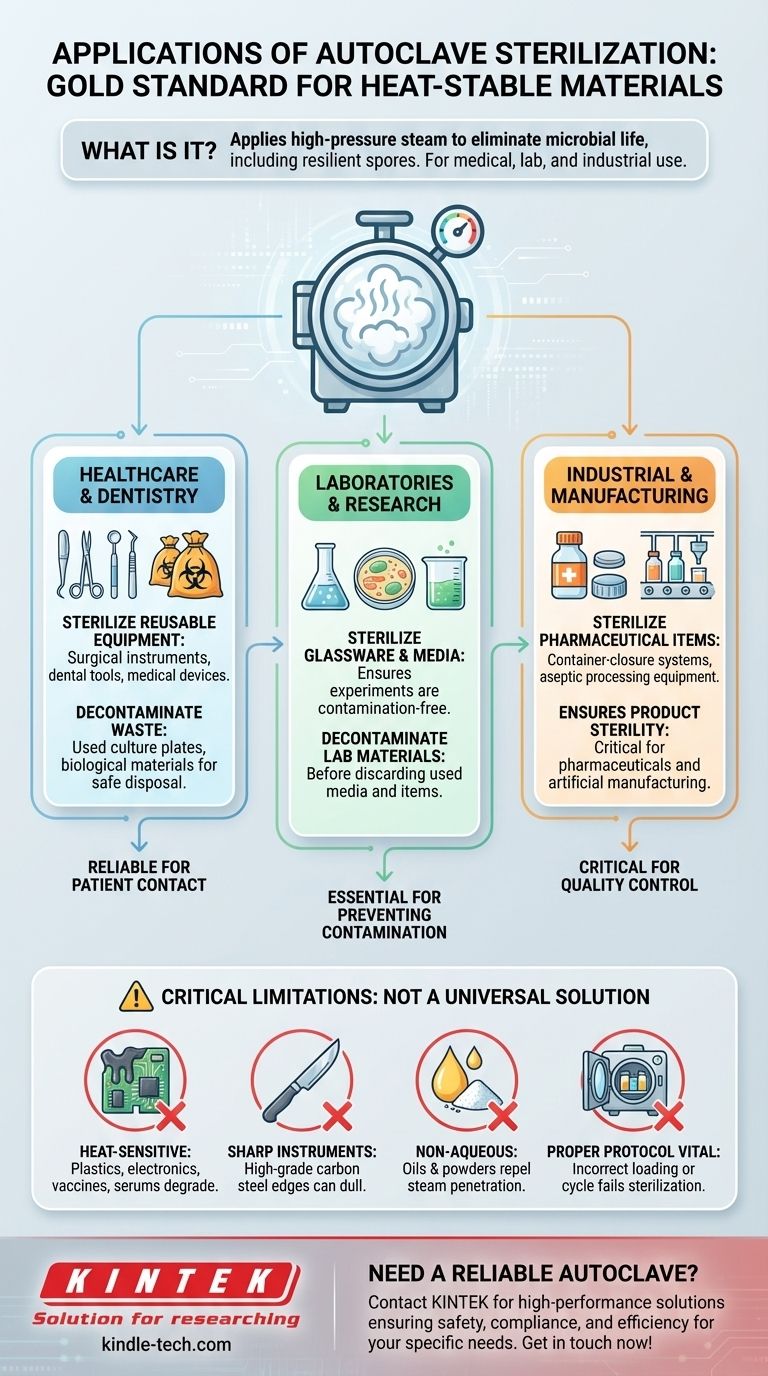

In essence, autoclave sterilization is applied across medical, laboratory, and industrial settings to completely sterilize equipment and supplies that can withstand high temperatures and moisture. Its primary uses include sterilizing surgical instruments, laboratory glassware, microbiological media, and decontaminating hazardous waste. The process uses high-pressure steam to reliably eliminate all forms of microbial life, including resilient bacterial spores.

The core principle to understand is that an autoclave is the gold standard for sterilizing heat-stable and water-compatible materials. However, its effectiveness is entirely dependent on this mechanism, making it fundamentally unsuitable for anything that high heat or moisture would damage.

How Autoclave Sterilization Works

To understand its applications, you must first understand its mechanism. An autoclave does not simply use heat; it uses steam under pressure, which is far more effective at transferring lethal energy to microbes.

The Principle of Steam Under Pressure

An autoclave functions by elevating the boiling point of water. By increasing the pressure inside a sealed chamber, it can generate steam at temperatures far above 100°C (212°F).

This high-pressure steam is key. It rapidly penetrates materials and transfers heat, denaturing the essential proteins and enzymes of microbes, including tough-to-kill bacterial endospores.

The Three Phases of Sterilization

A typical autoclave cycle is a controlled, three-part process to ensure air is removed and steam contact is maximized.

- The Purge Phase: Air, which is a poor conductor of heat, is removed from the chamber and displaced by incoming steam. Both pressure and temperature begin to rise.

- The Exposure (Sterilization) Phase: With all air purged, the chamber is held at a target temperature and pressure (e.g., 121°C at 15 psi) for a specific duration. This is when the actual killing of microbes occurs.

- The Exhaust Phase: The steam is released, and the pressure within the chamber returns to the ambient level, allowing the sterilized items to be safely removed.

Core Applications Across Industries

The autoclave's reliability makes it an indispensable tool in any field requiring absolute sterility.

In Healthcare and Dentistry

This is the most well-known application. Autoclaves are used to sterilize reusable surgical equipment, dental instruments, and other medical devices that come into contact with patients.

They are also critical for decontaminating medical waste, such as used culture plates and other biological materials, rendering them safe for disposal.

In Laboratories and Research

In microbiology, mycology, and other life sciences, autoclaves are used daily. They sterilize glassware, liquid solutions, and the nutrient-rich media used to grow microorganisms.

This ensures that experiments are not contaminated by unwanted microbes. They are also used to decontaminate used media and lab materials before they are discarded.

In Industrial and Manufacturing Settings

Fields like pharmaceuticals and artificial manufacturing rely on sterile conditions. Autoclaves are used to sterilize pharmaceutical items, container-closure systems, and equipment used in aseptic processing lines.

Understanding the Critical Limitations

An autoclave is a powerful tool, but it is not a universal solution. Using it on the wrong material can destroy the item and lead to failed sterilization.

Heat-Sensitive Materials

Many materials cannot withstand the high temperatures. This includes most plastics, which can melt or deform, and complex electronics.

Furthermore, sensitive biological compounds like vaccines, serums, and certain proteins will degrade and lose their function, requiring alternative methods like sterile filtration.

Sharp Instruments

While many surgical tools are autoclaved, very sharp instruments made of high-grade carbon steel can become dull. The high heat and moisture can subtly alter the fine cutting edge.

Non-Aqueous and Oily Substances

The sterilization mechanism relies on steam. Oils, powders, and other water-insoluble substances cannot be sterilized this way because the steam cannot penetrate them to transfer heat effectively.

The Importance of Proper Protocol

Effective sterilization is not just about having an autoclave; it is about using it correctly. Improper loading, failing to allow for steam penetration, or incorrect cycle times can result in non-sterile items, creating a significant risk.

Making the Right Choice for Your Goal

To ensure both safety and the integrity of your materials, you must match the item to the sterilization method.

- If your primary focus is robust surgical tools, glassware, or biological waste: The autoclave is your most reliable and effective choice.

- If your primary focus is heat-sensitive plastics, serums, or vaccines: An autoclave will cause irreversible damage, and you must use non-heat methods like filtration or chemical sterilization.

- If your primary focus is sterilizing powders or oily liquids: Steam cannot penetrate these substances, and you should use methods like dry heat sterilization instead.

- If your primary focus is delicate, sharp carbon-steel instruments: Consider alternative sterilization methods to avoid dulling the cutting edge.

Understanding these fundamental boundaries is the key to achieving effective sterilization while preserving the integrity of your materials.

Summary Table:

| Application Area | Key Uses | Key Considerations |

|---|---|---|

| Healthcare & Dentistry | Sterilizing surgical instruments, dental tools, decontaminating medical waste | Ideal for reusable, heat-stable items; unsuitable for very sharp carbon steel instruments that may dull |

| Laboratories & Research | Sterilizing glassware, microbiological media, decontaminating lab waste | Essential for preventing contamination in experiments; cannot be used for heat-sensitive biologicals like vaccines |

| Industrial & Manufacturing | Sterilizing pharmaceutical items, container-closure systems, aseptic processing equipment | Ensures product sterility; ineffective for powders, oils, and non-aqueous substances |

Need a reliable autoclave for your sterilization needs? KINTEK specializes in high-performance lab equipment, including autoclaves designed for medical, laboratory, and industrial applications. Whether you require precise sterilization for surgical instruments, laboratory glassware, or pharmaceutical manufacturing, our solutions ensure safety, compliance, and efficiency. Contact us today to find the perfect autoclave for your specific requirements and enhance your sterilization protocols. Get in touch now!

Visual Guide

Related Products

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- What is the function of a Teflon-lined stainless steel autoclave in rGO/TiO2 synthesis? Key Role in Nanocomposites

- How do you use an autoclave in a microbiology lab? Master Sterilization for Lab Safety & Accuracy

- What does an autoclave do to microorganisms? How It Achieves Sterilization with Steam

- What are the advantages of autoclave? Achieve Unmatched Sterilization Efficiency and Reliability

- What role does a static autoclave play in PWSCC testing of Alloy 600? Simulating Extreme Reactor Conditions

- What are the specifications of a laboratory autoclave? A Guide to Key Features for Safe Sterilization

- Why are hydrothermal synthesis autoclaves used for mesoporous HA catalysts? Engineering Superior Catalytic Efficiency

- What is process monitoring in the context of a decontamination process? Ensure Safety and Compliance