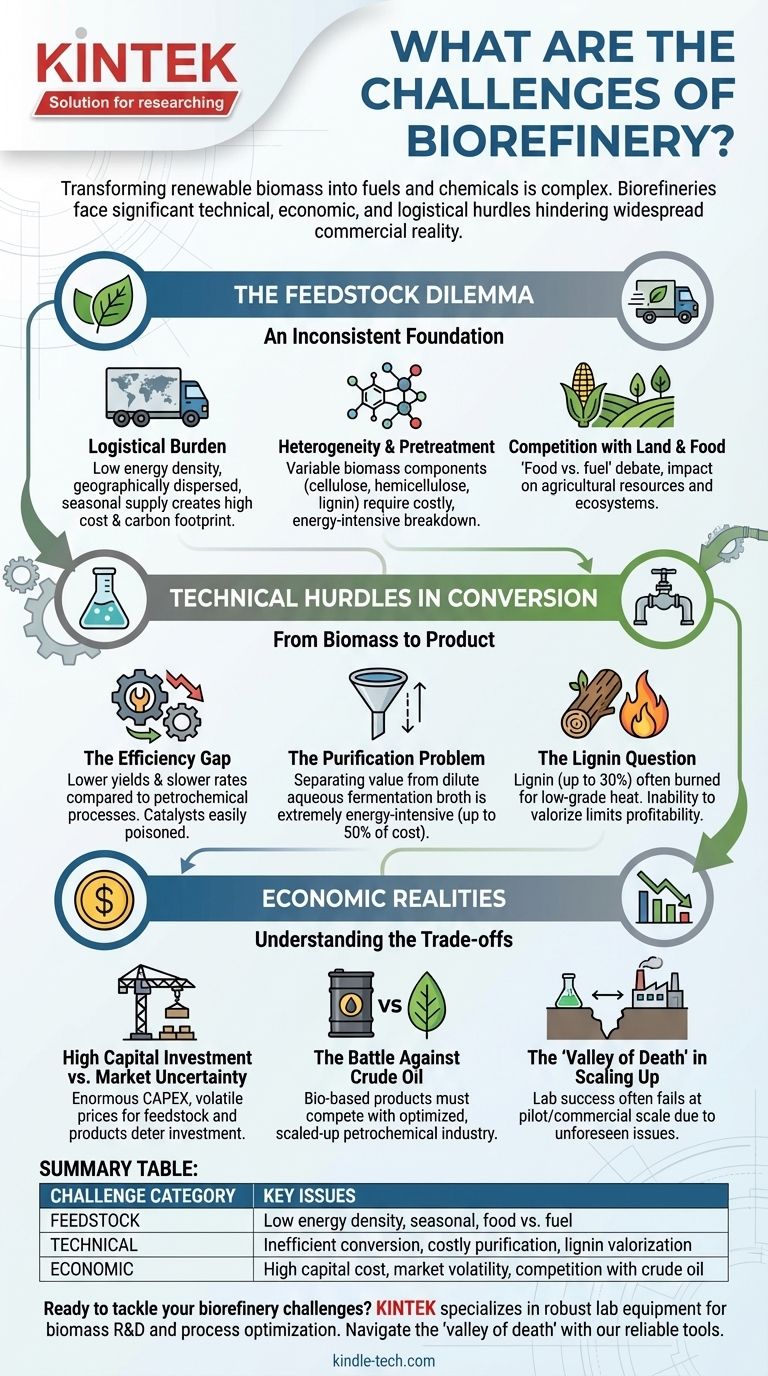

At its core, a biorefinery promises to transform renewable biomass into fuels and chemicals, mirroring a traditional petroleum refinery but with a sustainable foundation. However, the journey from this concept to widespread commercial reality is fraught with significant technical, economic, and logistical challenges that have slowed its adoption.

The central challenge is that biorefineries must overcome a trifecta of obstacles simultaneously: a highly variable and difficult-to-process feedstock, conversion technologies that are often inefficient and expensive, and intense market competition from the deeply entrenched and highly optimized petrochemical industry.

The Feedstock Dilemma: An Inconsistent Foundation

Unlike crude oil, which is a relatively uniform and energy-dense liquid, biomass is bulky, wet, and chemically complex. This creates immense challenges before any conversion can even begin.

The Logistical Burden of Biomass

Biomass has low energy density and is often geographically dispersed and seasonal. This means vast quantities must be harvested, collected, and transported to a central processing facility.

These logistics create a significant cost and carbon footprint, often undermining the economic and environmental viability of the entire operation. Securing a stable, affordable, year-round supply is a primary operational hurdle.

The Challenge of Heterogeneity and Pretreatment

Biomass is not a single chemical; it is a complex composite of cellulose, hemicellulose, and lignin. The precise ratio of these components varies dramatically between sources (e.g., wood chips vs. corn stover vs. algae).

This variability requires robust and often costly pretreatment steps to break down the rigid structure and separate the components. This initial stage is energy-intensive and can produce inhibitors that complicate downstream processing.

Competition with Land and Food

First-generation biorefineries, which use feedstocks like corn and sugarcane, create direct competition for agricultural land and resources. This raises ethical concerns and market tensions known as the "food vs. fuel" debate.

While next-generation technologies focus on non-food biomass (lignocellulosics), the demand for land and potential impact on ecosystems remain critical points of concern.

Technical Hurdles in the Conversion Process

Once the biomass is pretreated, converting it into valuable products presents another set of formidable scientific and engineering challenges.

The Efficiency Gap: From Biomass to Product

Biological and thermochemical conversion pathways, such as enzymatic hydrolysis or gasification, often suffer from lower yields and slower reaction rates compared to conventional petrochemical processes.

Furthermore, the catalysts and enzymes used are expensive and can be easily deactivated or "poisoned" by impurities present in the raw biomass, leading to high operational costs and process instability.

The Purification Problem: Separating Value from Water

Biorefinery processes frequently occur in a dilute aqueous environment. The result is a complex mixture—often called a "fermentation broth"—containing the desired product in low concentrations.

Separating and purifying this product to commercial-grade specifications is one of the most significant and underestimated challenges. This step is extremely energy-intensive and can account for over 50% of the total production cost, often rendering an otherwise promising technology uneconomical.

The Lignin Question: Waste Stream or Value Stream?

Lignin is a major component of biomass (up to 30%) but is notoriously difficult to break down into valuable chemicals. For many biorefineries, it is simply burned for low-grade heat and power.

The inability to convert lignin into high-value products—a process known as lignin valorization—severely limits the overall profitability of a biorefinery. True success depends on using every part of the biomass, not just the sugar-based components.

Understanding the Trade-offs: Economic Realities

Ultimately, a biorefinery must be profitable. The economic landscape is perhaps the most significant barrier to widespread deployment.

High Capital Investment vs. Market Uncertainty

Building a biorefinery requires enormous capital expenditure (CAPEX), often exceeding that of a petroleum refinery of equivalent output due to the complex pretreatment and separation equipment needed.

This high upfront risk is compounded by volatile market prices for both the biomass feedstock and the final products, making it difficult to secure long-term investment.

The Battle Against Crude Oil Prices

Bio-based chemicals and fuels must compete directly with their fossil-fuel-derived counterparts. The petrochemical industry benefits from decades of optimization, massive economies of scale, and a fully developed infrastructure.

When the price of crude oil is low, it becomes nearly impossible for most biorefinery products to compete on cost alone, regardless of their environmental benefits.

The "Valley of Death" in Scaling Up

A process that works perfectly in the laboratory often fails to remain technically or economically viable at a pilot or commercial scale. This gap between research and industrial application is known as the "valley of death."

Unforeseen issues with equipment fouling, process stability, and cost overruns frequently derail promising biorefinery projects during scale-up.

Charting a Path Forward for Biorefineries

Addressing these challenges requires a multi-faceted approach that integrates technological innovation with smart policy and economic strategy. Based on your objective, consider the following focal points:

- If your primary focus is technology development: Concentrate on creating robust, impurity-tolerant catalysts and developing low-energy, highly efficient separation and purification techniques.

- If your primary focus is investment or policy: Prioritize integrated models that valorize all biomass components, especially lignin, and are supported by stable, long-term carbon pricing or offtake agreements.

- If your primary focus is supply chain logistics: Investigate decentralized, regional processing hubs to minimize transportation costs and better manage the variability of local feedstock supplies.

Overcoming these challenges is a critical step toward diversifying our resource base and building a truly sustainable industrial economy.

Summary Table:

| Challenge Category | Key Issues |

|---|---|

| Feedstock | Low energy density, seasonal availability, food vs. fuel debate |

| Technical | Inefficient conversion, costly purification, lignin valorization |

| Economic | High capital cost, market volatility, competition with crude oil |

Ready to tackle your biorefinery challenges with precision equipment? KINTEK specializes in supplying robust lab equipment and consumables essential for R&D in biomass conversion, catalyst testing, and process optimization. Our reliable tools help you navigate the 'valley of death' in scaling up from lab to pilot plant. Contact us today to discuss how our solutions can enhance your biorefinery research and development. Get in touch via our Contact Form

Visual Guide

Related Products

People Also Ask

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time