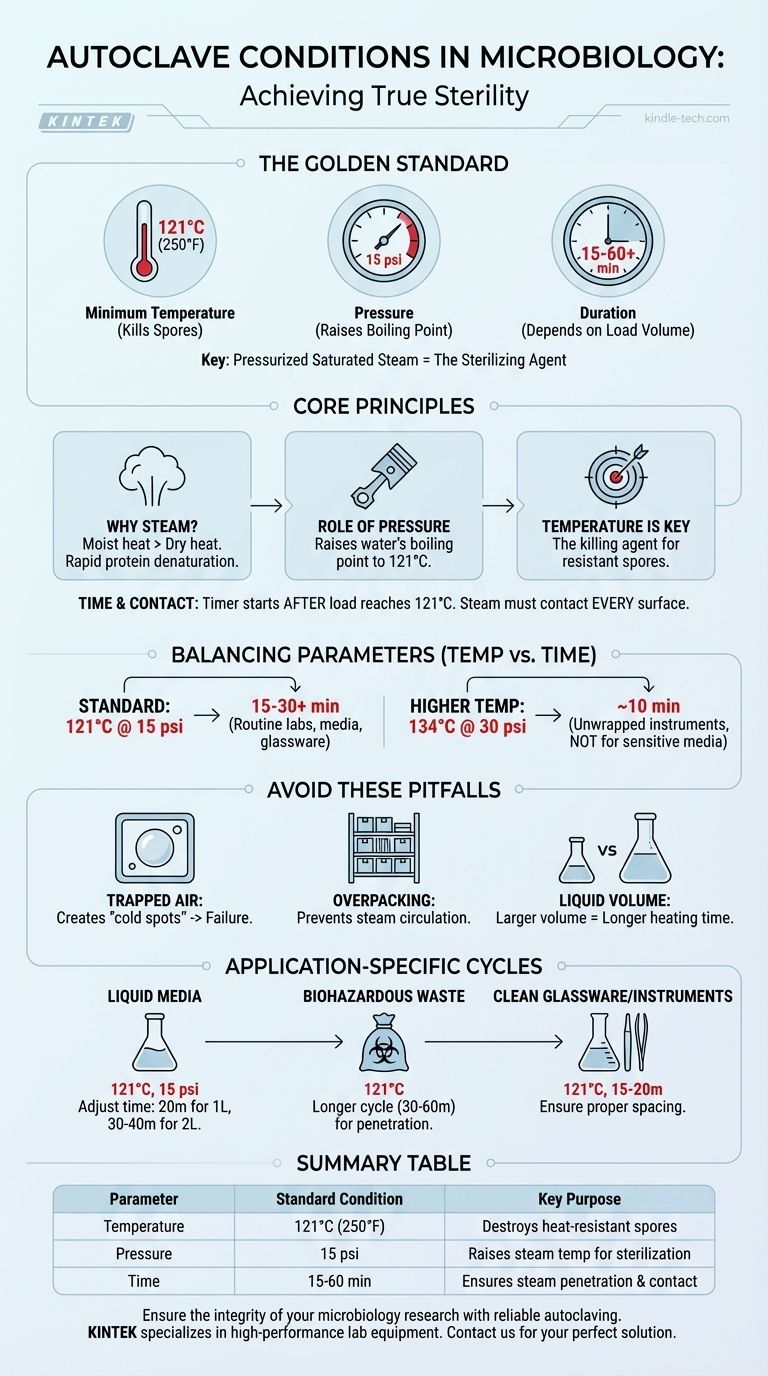

The standard conditions for autoclaving in microbiology are a temperature of at least 121°C (250°F) and a pressure of approximately 15 pounds per square inch (psi), maintained for a minimum of 15 to 20 minutes. The exact duration often extends from 30 to 60 minutes depending on the volume and density of the material being sterilized. These conditions are designed to use pressurized saturated steam to kill all forms of microorganisms, including highly resistant bacterial spores.

Autoclaving is not just about heat; it's about using pressurized saturated steam as the sterilizing agent. The pressure allows the steam to reach temperatures above water's normal boiling point, ensuring the rapid and complete destruction of all microbial life for truly sterile lab materials.

The Core Principles of Autoclave Sterilization

To use an autoclave effectively, it's crucial to understand the scientific principles that make it work. The interplay between steam, pressure, and temperature is the key to achieving sterility.

Why Steam, Not Just Dry Heat?

Moist heat is far more effective at sterilization than dry heat. Steam efficiently transfers thermal energy to microorganisms, rapidly denaturing the essential proteins and enzymes they need to survive.

The Critical Role of Pressure

At normal atmospheric pressure, water boils at 100°C (212°F). This temperature is sufficient to kill many bacteria, but not the resilient endospores some species form.

By increasing the pressure inside the autoclave chamber to 15 psi above atmospheric pressure, the boiling point of water is raised to 121°C. This higher temperature is the industry standard for destroying spores.

Temperature as the Killing Agent

The target temperature of 121°C is the universally accepted minimum required to ensure the destruction of the most heat-resistant bacterial spores. If the autoclave fails to reach and hold this temperature, sterility cannot be guaranteed.

The Importance of Time and Contact

The sterilization timer should only begin after the material inside the chamber—not just the chamber itself—has reached the target temperature of 121°C.

For sterilization to be successful, steam must make direct contact with every surface of the items being processed.

The Relationship Between Temperature, Pressure, and Time

While 121°C is the standard, different settings can be used. The key relationship to remember is that higher temperatures and pressures allow for shorter sterilization times.

Standard Conditions for Most Lab Applications

The baseline of 121°C at 15 psi for 15-20 minutes is suitable for most routine applications, such as sterilizing small volumes of liquid media, glassware, and lab utensils. For larger or more complex loads, this time is often extended to 30 minutes or more.

Higher Temperature, Shorter Time

Some autoclaves can operate at higher settings, such as 134°C (273°F) at 30 psi (206 kPa). At this temperature, sterilization can be achieved in as little as 10 minutes. This is common for sterilizing unwrapped, non-porous instruments but may be too harsh for sensitive culture media, which can degrade.

Common Pitfalls to Avoid

Achieving true sterility requires more than just setting the correct numbers. Avoiding common operational errors is essential for safety and experimental success.

The Danger of Trapped Air

Air pockets are the primary enemy of effective sterilization. If air is not fully purged from the chamber, it creates "cold spots" where the temperature will not reach 121°C, leading to sterilization failure. Modern autoclaves have cycles designed to remove this air.

Overpacking the Autoclave

Loading items too tightly prevents steam from circulating and penetrating the entire load. Always leave adequate space between items to ensure all surfaces are exposed to the steam.

Liquid Volume Considerations

A large flask of liquid media takes much longer to heat than a small one. The cycle time must be long enough for the core of the largest liquid volume to reach 121°C and stay there for the required duration. A 15-minute cycle may be insufficient for a 2-liter flask.

How to Apply This to Your Goal

Select your autoclave cycle based on the specific material you need to sterilize to ensure both effectiveness and material integrity.

- If your primary focus is sterilizing liquid culture media: Use a standard cycle of 121°C at 15 psi, but adjust the time for volume—at least 20 minutes for 1L and 30-40 minutes for 2L containers.

- If your primary focus is decontaminating biohazardous waste: Use a longer cycle, such as 30-60 minutes at 121°C, to guarantee complete steam penetration through dense materials like used agar plates.

- If your primary focus is sterilizing clean glassware or metal instruments: A standard 15-20 minute cycle at 121°C is highly effective, provided items are spaced properly to allow full steam contact.

Mastering these conditions ensures the integrity of your research and the safety of your laboratory environment.

Summary Table:

| Parameter | Standard Condition | Key Purpose |

|---|---|---|

| Temperature | 121°C (250°F) | Destroys heat-resistant bacterial spores |

| Pressure | 15 psi above atmospheric pressure | Raises steam temperature for effective sterilization |

| Time | 15-60 minutes (depends on load) | Ensures steam penetration and contact with all surfaces |

Ensure the integrity of your microbiology research with reliable autoclaving. KINTEK specializes in high-performance lab equipment and consumables, providing autoclaves and expert support to meet your laboratory's sterilization needs. Contact us today to find the perfect autoclave solution for your lab!

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

People Also Ask

- What is the normal temperature of an autoclave? Achieve Sterile Confidence with Precise Control

- What kind of hazard can a lab personnel experienced in working with autoclave? Avoid Complacency with These Critical Risks

- What critical environmental conditions does a high-pressure autoclave provide? Mastering FeCrAl Alloy Corrosion Testing

- What is the process of autoclave sterilization? Master the Key Steps for 100% Sterility

- Why is a Teflon-lined stainless steel autoclave necessary for BixIn2-xO3 synthesis? Enhance Your Nanocrystal Purity

- What is the maximum pressure in an autoclave? A Guide to Safe and Effective Sterilization

- What is the most commonly used autoclave? Discover the Industry Standard for Sterilization

- What can you use an autoclave for? Essential Sterilization for Medical, Lab, and Industrial Needs