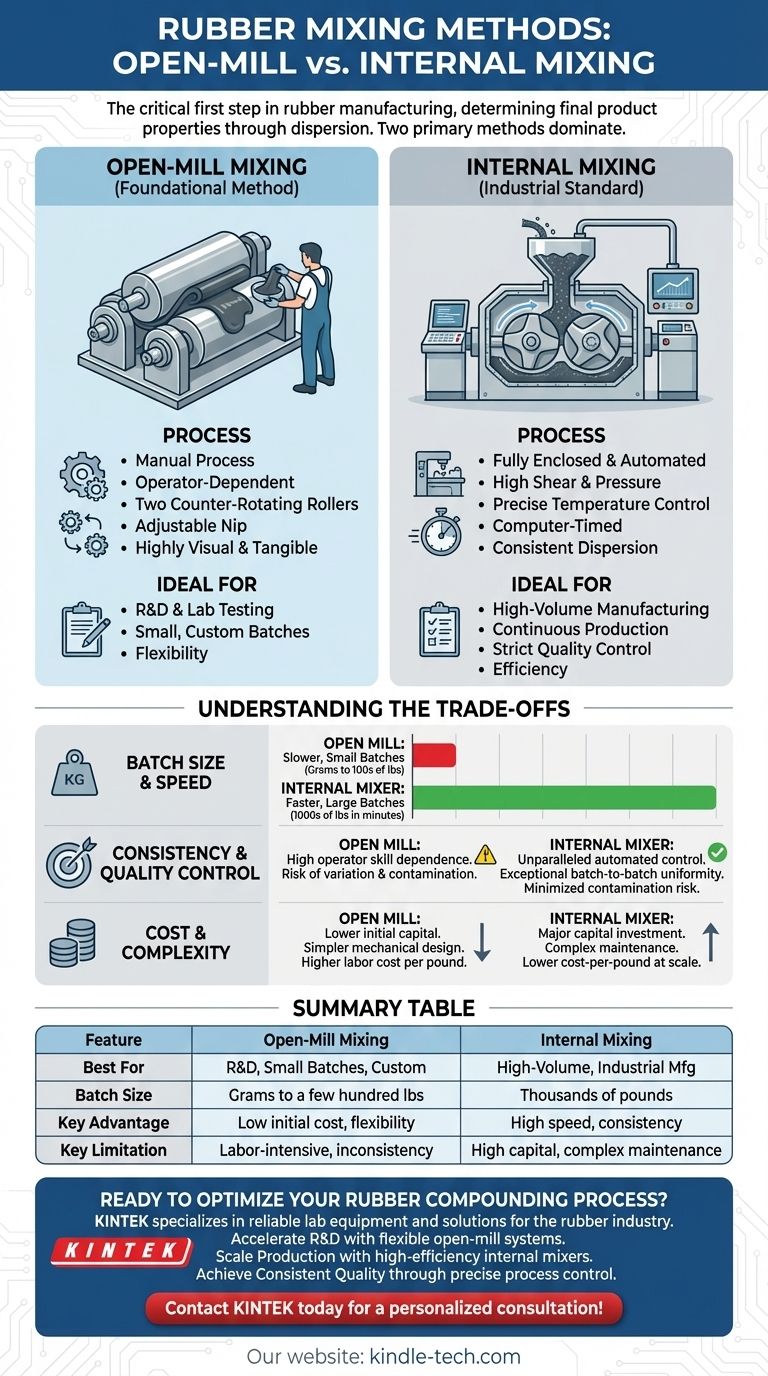

In rubber manufacturing, the properties of the final product are determined long before it takes shape. The critical first step is mixing, where two primary methods dominate: open-mill mixing and internal mixing. Open-mill mixing is a traditional, manual process suited for small batches, while internal mixers are enclosed, automated systems designed for high-volume, high-consistency production.

The choice between rubber mixing methods is a strategic decision dictated by production scale and quality requirements. Open mills offer flexibility for development and small runs, whereas internal mixers deliver the efficiency and control essential for mass production.

The Two Pillars of Rubber Compounding

The goal of mixing, or compounding, is to uniformly disperse additives like fillers, accelerators, and protectants into a raw rubber polymer. The method used to achieve this dispersion directly impacts the cost, consistency, and performance of the final rubber material.

Open-Mill Mixing: The Foundational Method

An open mill consists of two large, counter-rotating steel rollers. The gap between them, known as the "nip," is adjustable.

An operator manually adds the raw rubber to the moving rolls, where it softens from the heat and shear. The various additives are then introduced into the nip, and the operator cuts and folds the rubber sheet back onto itself repeatedly to ensure a homogenous blend.

This method is highly visual and tangible, allowing for on-the-fly adjustments. Its simplicity makes it invaluable for laboratory testing and small-scale, custom batches.

Internal Mixing: The Industrial Standard

An internal mixer, such as the common Banbury® mixer, is a fully enclosed chamber with two rotating, specially shaped rotors.

Raw materials are fed into the chamber through a hopper. Inside, the rotors' geometry creates immense shear forces, mixing the compound under high pressure and controlled temperatures. The entire process is automated and precisely timed.

This method is the standard for nearly all large-scale rubber manufacturing due to its speed, efficiency, and superior ability to produce a consistent, uniform compound batch after batch.

Understanding the Trade-offs

Choosing a mixing method involves balancing speed, consistency, and cost. Each approach presents a distinct set of advantages and limitations.

Batch Size and Speed

An open mill is inherently slower, as the process is manual and limited by the operator's ability to work the material. It is best suited for batches ranging from a few grams for lab work to a few hundred pounds.

An internal mixer is designed for speed and volume. It can process batches of thousands of pounds in just a few minutes, making it the only practical choice for industrial-scale production.

Consistency and Quality Control

Consistency in open-mill mixing is highly dependent on operator skill. This introduces a risk of variation between batches and even within a single batch. The open design also increases the potential for contamination from the environment.

The enclosed, automated nature of an internal mixer provides unparalleled control. By managing time, temperature, and pressure with precision, it delivers exceptional batch-to-batch uniformity and minimizes any risk of contamination.

Cost and Complexity

Open mills have a significantly lower initial capital cost and a simpler mechanical design. However, they are labor-intensive, which results in a higher processing cost per pound of rubber.

Internal mixers represent a major capital investment and are more complex to maintain. At scale, their high throughput and low labor requirements lead to a much lower cost-per-pound, making them far more economical for mass production.

Making the Right Choice for Your Goal

Selecting the appropriate mixing process is fundamental to achieving your production and quality objectives.

- If your primary focus is R&D or custom, small-batch production: An open mill offers the essential flexibility, hands-on control, and lower initial cost for development work.

- If your primary focus is high-volume manufacturing with strict quality control: An internal mixer is the definitive solution for achieving the efficiency, speed, and consistency required for large-scale operations.

- If your primary focus is balancing cost-efficiency with volume: The break-even point is key; open mills are more economical for small, infrequent runs, while internal mixers provide superior ROI for continuous, high-volume production.

Ultimately, understanding the fundamental capabilities of each mixing method empowers you to align your manufacturing strategy with your specific quality and output targets.

Summary Table:

| Mixing Method | Best For | Batch Size | Key Advantage | Key Limitation |

|---|---|---|---|---|

| Open-Mill Mixing | R&D, Small Batches, Custom Production | Grams to a few hundred pounds | Low initial cost, operator flexibility | Labor-intensive, potential for batch inconsistency |

| Internal Mixing | High-Volume, Industrial Manufacturing | Thousands of pounds | High speed, superior batch-to-batch consistency | High capital investment, complex maintenance |

Ready to Optimize Your Rubber Compounding Process?

Selecting the right mixing equipment is critical to the quality, consistency, and cost-efficiency of your rubber products. Whether you are developing new compounds in the lab or scaling up for mass production, KINTEK has the expertise and equipment solutions to meet your needs.

We specialize in providing reliable lab equipment and consumables for the rubber industry, helping you:

- Accelerate R&D with flexible open-mill systems.

- Scale Production with high-efficiency internal mixers.

- Achieve Consistent Quality through precise process control.

Let our experts help you choose the perfect mixing solution for your specific goals. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- How does a laboratory stirrer influence MOF product quality? Master Precision in Non-Solvothermal Synthesis

- What role does a laboratory shaker play in the extraction of plant compounds for green synthesis? Maximize Your Yield

- What role does high-speed stirring equipment play in fungal pre-cultures? Optimize Your Solid-State Fermentation

- Why is a high-precision orbital shaker required for chitin adsorption? Achieve Rapid Equilibrium & Precise Data

- What is the role of laboratory stirring equipment in nZVI preparation? Achieve Stable and Uniform Nano Slurries