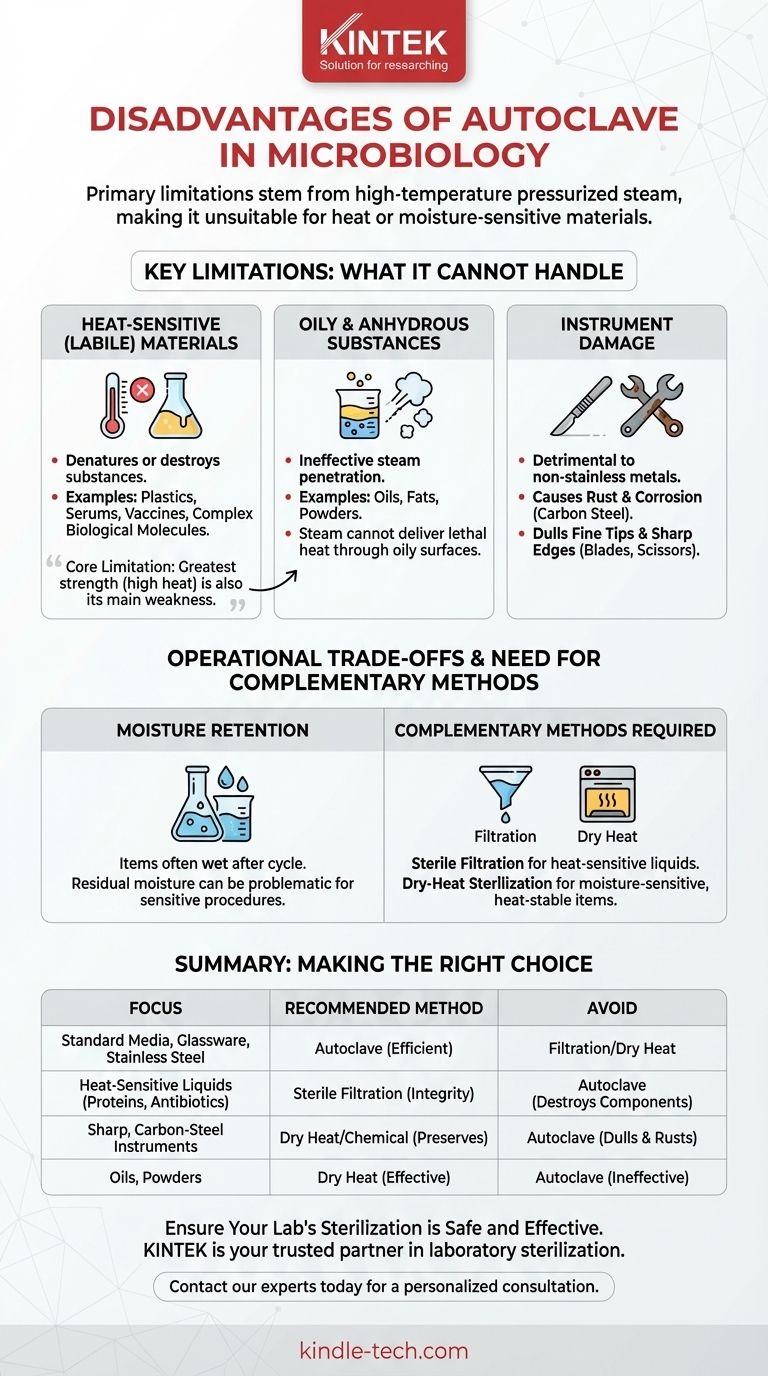

While indispensable in microbiology, the primary disadvantages of an autoclave stem from its reliance on high-temperature pressurized steam. This method is unsuitable for any materials that are sensitive to heat, moisture, or both. Consequently, it can damage certain instruments, destroy essential compounds in media, and is completely ineffective for oily or dry substances.

The core limitation of an autoclave is that its greatest strength—the use of high-heat steam—is also its main weakness. Understanding which materials cannot withstand heat and moisture is critical to preventing damage to equipment and ensuring the successful sterilization of your materials.

The Autoclave's Essential Role in Microbiology

Before examining its limitations, it's important to recognize the autoclave's fundamental purpose. It is the workhorse of most microbiology labs for two main reasons.

Preparing Sterile Growth Environments

The autoclave is the gold standard for sterilizing culture media, reagents, and durable lab equipment like glassware and stainless steel instruments. This ensures that experiments begin in a completely sterile environment, free from contaminating microorganisms.

Decontaminating Biohazardous Waste

After experiments are complete, autoclaves are used to decontaminate biohazardous waste, such as used petri dishes and liquid cultures. The process effectively kills all pathogens, allowing for safe and cost-effective disposal.

Key Disadvantages: What Autoclaves Cannot Handle

The effectiveness of an autoclave is entirely dependent on the ability of steam to penetrate and heat an object. This creates clear boundaries for its use.

Heat-Sensitive (Labile) Materials

High temperatures will denature or destroy many substances. This is the most common reason to seek an alternative to autoclaving.

Items in this category include many plastics that can melt or warp, as well as complex biological molecules. Solutions containing serums, certain vitamins, or vaccines will be rendered useless as the proteins and other compounds degrade.

Oily and Anhydrous (Water-Free) Substances

An autoclave sterilizes by transferring heat via steam condensation. This process is ineffective for substances that repel water.

Oils, fats, and powders cannot be sterilized by this method because steam cannot penetrate them to deliver lethal heat. The oily surface prevents the necessary contact.

Damage to Specific Instruments

While excellent for stainless steel, the autoclave is detrimental to other types of metal instruments.

The high moisture content will cause carbon steel instruments to rust and corrode. Furthermore, the extreme heat can dull the fine tips and sharp edges of scalpels, blades, and high-grade scissors, compromising their function.

Understanding the Operational Trade-offs

Beyond material incompatibility, the process itself has inherent trade-offs that require consideration.

The Problem of Moisture Retention

Because the process uses steam, autoclaved items are often wet at the end of a cycle. While many autoclaves have a drying phase, it may not be sufficient for all applications, and residual moisture can be a problem for certain sensitive procedures.

The Need for Complementary Methods

The limitations of autoclaving mean that no microbiology lab can rely on it exclusively. Effective sterilization protocol requires a multi-faceted approach.

For heat-sensitive liquids like serum or antibiotic solutions, sterile filtration is the necessary alternative. For items that are damaged by moisture but can withstand high temperatures, dry-heat sterilization is often used.

Making the Right Choice for Your Task

Ultimately, the autoclave is a powerful tool when used correctly. Your choice of sterilization method must be guided by the material you are working with.

- If your primary focus is sterilizing standard liquid media, glassware, or stainless steel: The autoclave is your most efficient and reliable choice.

- If your primary focus is sterilizing solutions with heat-sensitive proteins or antibiotics: You must use sterile filtration to avoid destroying the active components.

- If your primary focus is sterilizing sharp, carbon-steel instruments: Avoid the autoclave to prevent dulling and rust; consider dry heat or chemical sterilization instead.

- If your primary focus is sterilizing oils or powders: The autoclave is ineffective; dry-heat sterilization is the appropriate method.

Choosing the correct sterilization technique is a critical step in ensuring the integrity and safety of your microbiological work.

Summary Table:

| Disadvantage Category | Specific Examples | Impact |

|---|---|---|

| Heat-Sensitive Materials | Plastics, serums, vaccines | Denatures or destroys materials |

| Oily/Water-Free Substances | Oils, fats, powders | Steam cannot penetrate, ineffective sterilization |

| Instrument Damage | Carbon steel tools, sharp blades | Causes rust, corrosion, and dulling |

| Operational Trade-offs | Moisture retention, cycle time | Wet items, requires complementary methods |

Ensure Your Lab's Sterilization is Safe and Effective

Understanding the limitations of your autoclave is crucial for protecting valuable equipment and ensuring experiment integrity. The wrong sterilization method can lead to costly damage, contaminated samples, and compromised results.

KINTEK is your trusted partner in laboratory sterilization. We specialize in providing the right equipment and consumables for your specific microbiology needs. Whether you require autoclaves for standard media, filtration systems for heat-sensitive liquids, or dry-heat ovens for oils and sharp instruments, we have the solutions to keep your lab running safely and efficiently.

Don't let sterilization limitations hinder your research. Contact our experts today for a personalized consultation. We'll help you select the perfect equipment to protect your materials and ensure flawless sterilization every time.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- Why is a high-pressure circulating autoclave necessary for PWR corrosion testing? Replicating Nuclear Environments

- What lab supplies should be autoclaved? A Guide to Safe Sterilization and Decontamination

- What core conditions must a high-pressure autoclave meet for supercritical water corrosion? Master 27 MPa & 600°C Tests

- What role does a high-pressure autoclave play in simulating corrosive environments? Essential for Oil & Gas HPHT Testing

- What is the function of a High-Pressure Hydrothermal Autoclave in preparing mesoporous hydroxyapatite? Key Insights

- What is the primary purpose and principle of autoclaving? The Definitive Guide to Sterilization

- What are the most common hazards of using an autoclave? Avoid Burns, Explosions, and Sterilization Failures

- What is the difference between types of autoclave? Choose the Right Sterilization Method for Your Lab