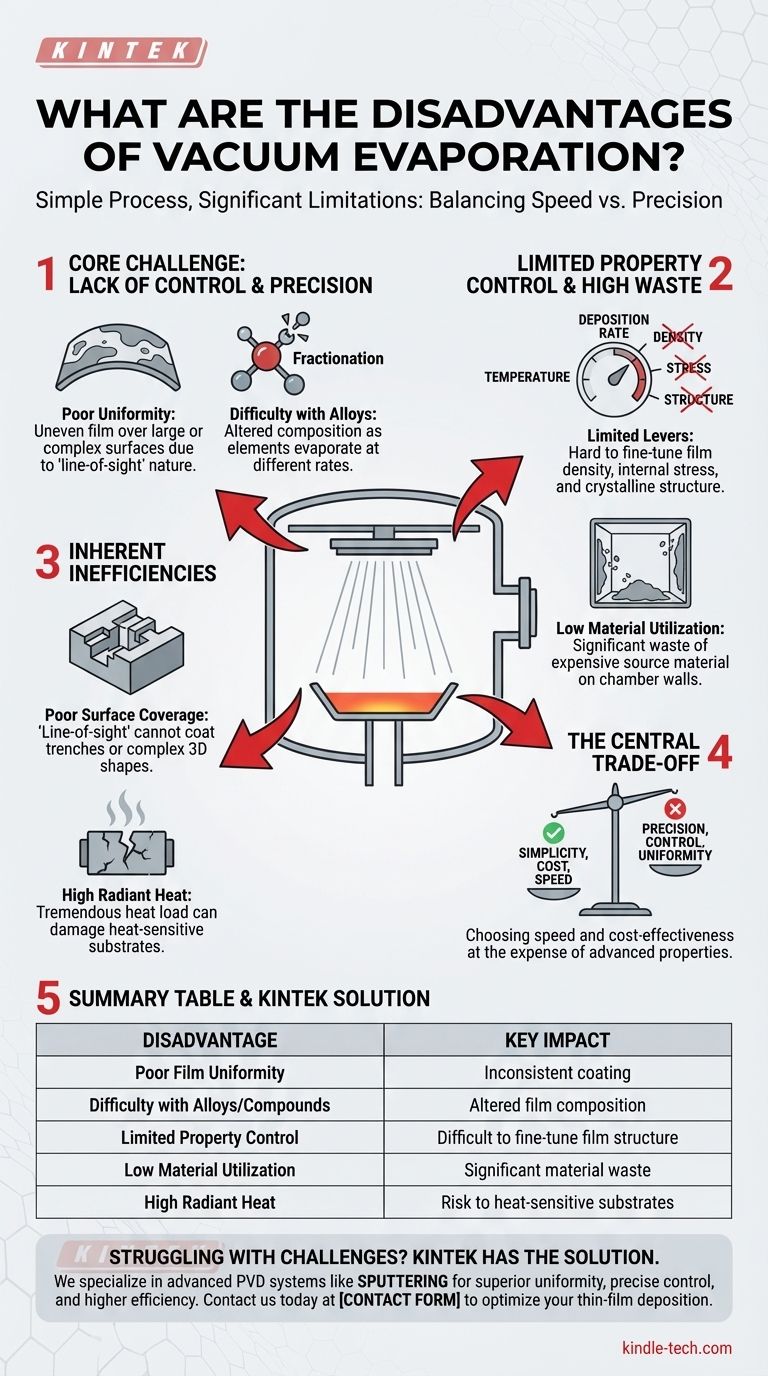

At its core, vacuum evaporation is a straightforward process, but this simplicity introduces significant limitations. Its primary disadvantages are poor film uniformity over large or complex surfaces, difficulty in depositing materials with multiple elements like alloys, limited control over the final film’s properties, and inefficient use of the source material.

The central trade-off of vacuum evaporation is choosing speed and simplicity at the expense of precision and control. While it is a cost-effective method for simple coatings, its "line-of-sight" nature and reliance on thermal energy create inherent challenges for advanced or complex applications.

The Core Challenge: Lack of Control and Precision

Vacuum evaporation is fundamentally a thermal process. A source material is heated in a vacuum until it evaporates, and the vapor travels in a straight line until it condenses on a cooler surface—the substrate. This simple mechanism is the root of its major drawbacks.

Difficulty with Alloys and Compounds

When you heat a material containing multiple elements (an alloy or compound), the element with the highest vapor pressure will evaporate faster. This means the composition of the vapor, and therefore the deposited film, will be different from the source material, a problem known as fractionation.

Achieving the correct stoichiometry for a complex film is exceptionally difficult with this method.

Limited Film Property Control

The primary control variable is temperature. Unlike more advanced Physical Vapor Deposition (PVD) methods like sputtering, there are few levers to pull to influence the film's final properties.

This makes it difficult to fine-tune characteristics such as film density, internal stress, or crystalline structure. The resulting film is often less dense and has poorer adhesion than one produced by a more energetic deposition process.

Poor Film-Thickness Uniformity

The source material evaporates outward like light from a bulb. Substrates positioned directly in front of the source receive a thick coating, while areas at an angle or further away receive a much thinner one.

Achieving uniform thickness over a large area or on multiple parts simultaneously requires complex and often expensive rotating fixtures.

Inherent Process Inefficiencies

The simplicity of the process also leads to waste and potential damage to the components being coated.

Poor Surface Coverage

The "line-of-sight" trajectory means the vapor cannot coat what it cannot "see." This results in very poor coverage on complex 3D shapes, in trenches, or on the sides of features.

This limitation, known as poor step coverage, makes it unsuitable for applications requiring a conformal coating that uniformly covers an entire component.

Low Material Utilization

Because the vapor radiates outwards from the source, a significant portion of the expensive source material ends up coating the inside of the vacuum chamber instead of the target substrates.

This inefficiency can dramatically increase costs, especially when working with precious metals like gold or platinum.

High Radiant Heat Loads

Heating the source to its evaporation point generates a tremendous amount of radiant heat. This heat can easily damage heat-sensitive substrates, such as plastics or delicate electronic components.

Understanding the Trade-offs: Why Choose It Anyway?

Despite these clear disadvantages, vacuum evaporation remains a widely used industrial process. Its weaknesses are accepted in exchange for a few key benefits.

Simplicity and Cost

It is generally the least expensive and simplest PVD process to implement and operate. For high-volume, low-complexity applications, this economic advantage is often the deciding factor.

High Purity and Speed

In the high vacuum environment, if you start with a high-purity source material, you can produce a very high-purity film. The deposition rates can also be very high, making it much faster than alternatives for certain materials.

Making the Right Choice for Your Goal

Selecting the right deposition method requires aligning the process capabilities with your specific outcome.

- If your primary focus is a simple, low-cost metallic coating on a relatively flat surface (e.g., decorative chrome, aluminum on reflectors): Vacuum evaporation is an excellent, cost-effective choice where its disadvantages have minimal impact.

- If your primary focus is depositing a complex alloy or compound film with precise properties (e.g., functional optical filters, semiconductors): The lack of compositional and structural control makes evaporation a poor choice; consider sputtering instead.

- If your primary focus is a uniform, conformal coating on a complex 3D object: You must either invest in highly sophisticated planetary fixturing or choose an alternative process with non-line-of-sight characteristics.

Ultimately, understanding the inherent limitations of vacuum evaporation is the key to using it effectively or choosing a more suitable alternative for your specific engineering challenge.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Poor Film Uniformity | Inconsistent coating on large or complex surfaces |

| Difficulty with Alloys/Compounds | Altered film composition due to fractionation |

| Limited Property Control | Difficult to fine-tune density, stress, or structure |

| Low Material Utilization | Significant waste of expensive source materials |

| High Radiant Heat | Risk of damaging heat-sensitive substrates |

Struggling with Thin-Film Deposition Challenges? KINTEK Has the Solution.

While vacuum evaporation has its place, advanced applications demand greater precision and control. KINTEK specializes in high-performance lab equipment, including advanced PVD systems like sputtering, that overcome the limitations of traditional evaporation.

We help you achieve:

- Superior film uniformity on complex geometries

- Precise stoichiometry for alloys and compound materials

- Enhanced control over film density and adhesion

- Higher material utilization to reduce costs

Whether you're working on optical coatings, semiconductor devices, or functional surfaces, our experts will help you select the right technology for your specific needs.

Contact us today at [#ContactForm] to discuss your project and discover how KINTEK's solutions can optimize your thin-film deposition process.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems