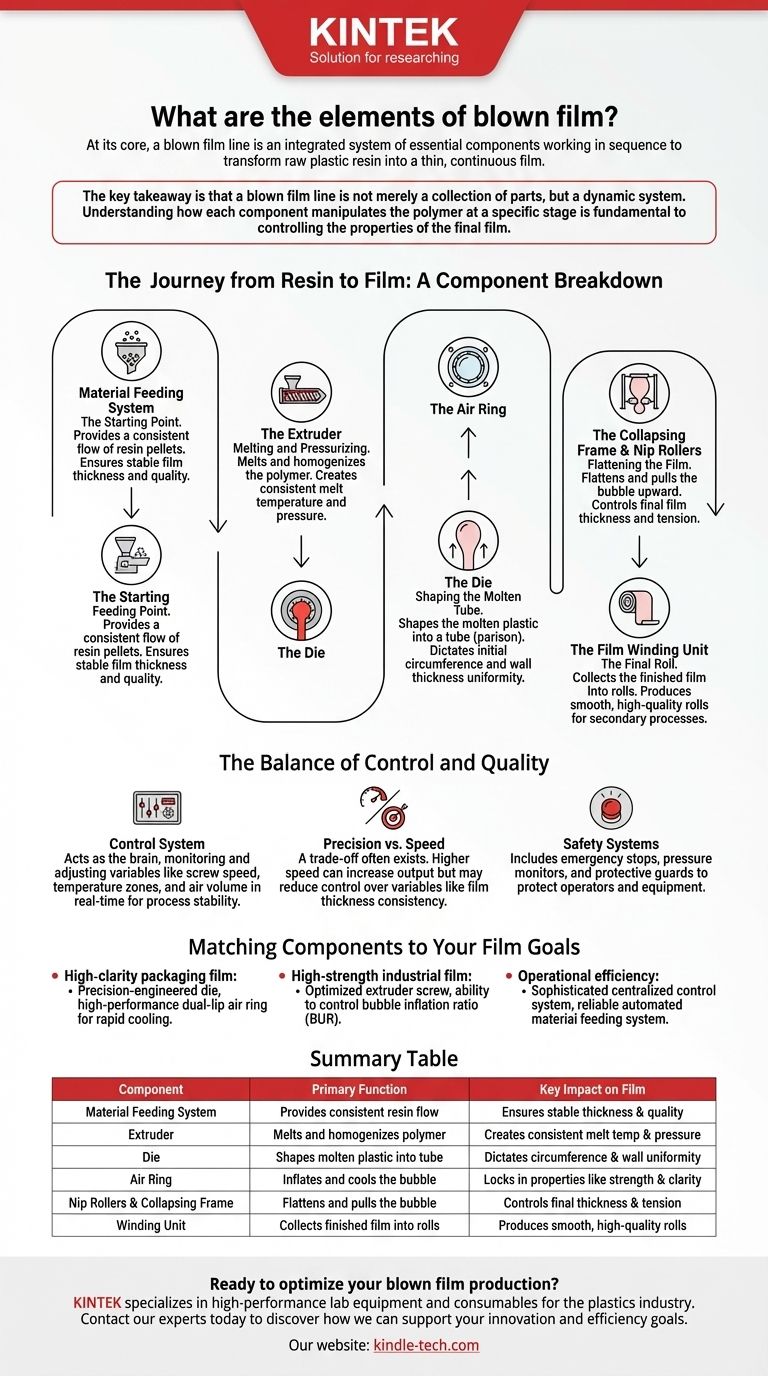

At its core, a blown film line is an integrated system of essential components working in sequence to transform raw plastic resin into a thin, continuous film. The primary operational elements include the material feeding system, the extruder, the die which shapes the molten plastic, the air ring that inflates and cools it, and the winding unit that collects the final product.

The key takeaway is that a blown film line is not merely a collection of parts, but a dynamic system. Understanding how each component manipulates the polymer at a specific stage—from melting to inflating to cooling—is fundamental to controlling the properties of the final film.

The Journey from Resin to Film: A Component Breakdown

The process of creating blown film is a continuous, vertical extrusion process. Each component has a distinct function that builds upon the last, transforming solid pellets into a precisely engineered film roll.

Material Feeding System: The Starting Point

The process begins here, where raw polymer pellets, or resin, are fed from a hopper into the extruder.

A reliable feeding system is critical for consistency. It ensures a constant, uniform flow of material, which is the first step in maintaining stable film thickness and quality down the line.

The Extruder: Melting and Pressurizing

Inside a heated barrel, a rotating screw conveys the resin forward. The friction and heat melt the pellets into a homogenous, molten polymer.

This stage is responsible for creating a consistent melt temperature and pressure, which is vital for the subsequent shaping process.

The Die: Shaping the Molten Tube

The molten plastic is forced through a circular die, emerging as a hollow, vertical tube of plastic known as a parison.

The precision of the die's design is paramount. It dictates the initial circumference of the film bubble and is a primary factor in ensuring uniform wall thickness.

The Air Ring: Inflating and Cooling the Bubble

Positioned directly above the die, the air ring blows a controlled, high-velocity stream of air onto the parison. This air serves two critical functions.

First, internal air is injected to inflate the tube into a large "bubble," stretching the plastic both radially and lengthwise. Second, external air from the ring cools the bubble, freezing the polymer chains in their oriented state. This step is where the film's final properties, like strength and clarity, are locked in.

The Collapsing Frame & Nip Rollers: Flattening the Film

Once the bubble has traveled upwards and cooled sufficiently, it is guided by a collapsing frame that gently flattens it into a lay-flat, two-layer tube.

A set of nip rollers at the top of the line pulls the bubble upward, maintaining tension and collapsing it without wrinkles. The speed of these rollers determines the final film thickness.

The Film Winding Unit: The Final Roll

After passing through the nip rollers, the flattened tube of film is wound into large master rolls.

Modern winders maintain constant tension to create smooth, high-quality rolls that are ready for secondary processes like printing, laminating, or bag making.

The Balance of Control and Quality

Achieving the desired film properties is a matter of managing the interplay between these components. The entire system is a delicate balance of speed, temperature, and pressure.

The Role of the Control System

An integrated control system acts as the brain of the entire line. It monitors and adjusts variables like screw speed, temperature zones, air volume, and winding speed in real-time.

This system ensures process stability and repeatability, which is essential for producing film that meets strict quality specifications with minimal waste.

Precision vs. Speed

There is often a trade-off between production speed and film quality. Running the line faster can increase output but may reduce control over variables like film thickness (gauge) consistency.

The sophistication of the die and air ring often determines how fast a line can run while maintaining high-quality output.

Safety Systems

Modern blown film lines operate at high temperatures and pressures. Safety systems, including emergency stops, pressure monitors, and protective guards, are non-negotiable components that protect operators and equipment.

Matching Components to Your Film Goals

The configuration of your blown film line should be dictated by the specific properties you need in your final product.

- If your primary focus is high-clarity packaging film: Your most critical components are a precision-engineered die and a high-performance dual-lip air ring for rapid, uniform cooling.

- If your primary focus is high-strength industrial film: The design of the extruder screw and the ability to control the bubble's inflation ratio (BUR) are paramount to achieving the desired molecular orientation and toughness.

- If your primary focus is operational efficiency: A sophisticated, centralized control system and a reliable, automated material feeding system are key to maximizing uptime and minimizing material waste.

Ultimately, mastering the blown film process comes from understanding that each component is a lever you can use to engineer the final material.

Summary Table:

| Component | Primary Function | Key Impact on Film |

|---|---|---|

| Material Feeding System | Provides a consistent flow of resin pellets. | Ensures stable film thickness and quality. |

| Extruder | Melts and homogenizes the polymer. | Creates consistent melt temperature and pressure. |

| Die | Shapes the molten plastic into a tube (parison). | Dictates initial circumference and wall thickness uniformity. |

| Air Ring | Inflates and cools the bubble. | Locks in final properties like strength and clarity. |

| Nip Rollers & Collapsing Frame | Flattens and pulls the bubble upward. | Controls final film thickness and tension. |

| Winding Unit | Collects the finished film into rolls. | Produces smooth, high-quality rolls for secondary processes. |

Ready to optimize your blown film production? KINTEK specializes in high-performance lab equipment and consumables for the plastics industry. Whether you are developing new film formulations, testing material properties, or ensuring quality control, our solutions are designed to meet your laboratory's specific needs. Contact our experts today to discover how we can support your innovation and efficiency goals.

Visual Guide

Related Products

- Anti-Cracking Press Mold for Lab Use

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What role does a high-purity graphite mold play during hot pressing? Optimize Boron Carbide Sintering at 1850°C

- Why is precise temperature and pressure control necessary for combustible cartridge cases? Ensure Structural Integrity

- What are the advantages of using high-strength graphite molds in the hot press sintering of Ti6Al4V-based composites?

- What role do high-temperature pressure molds play in SiCp/Al fabrication? Enhancing Densification and Thermal Uniformity

- What are the specific functions of graphite molds in the vacuum hot-press sintering process? Expert Insights for Ceramics