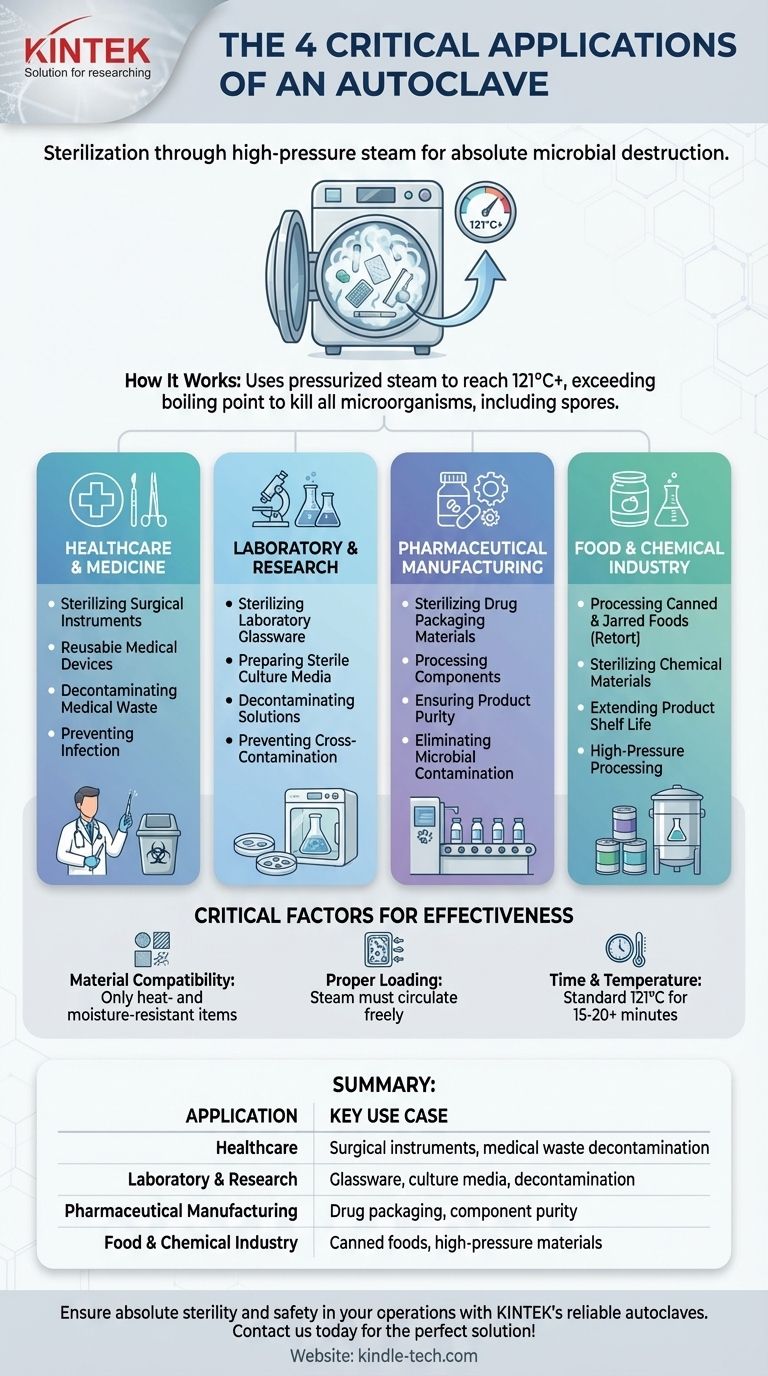

An autoclave's primary function is sterilization, and its applications are remarkably diverse and critical. The four most prominent applications are the sterilization of equipment in healthcare settings, the preparation of sterile media and decontamination of materials in research laboratories, ensuring purity in pharmaceutical manufacturing, and processing materials in the food industry.

An autoclave is more than a simple sterilizer; it is a precision instrument that uses high-pressure steam to achieve temperatures that are impossible under normal atmospheric pressure. This single capability—the total destruction of all microbial life—is the reason for its indispensable role across medicine, science, and industry.

The Core Principle: Sterilization Beyond Boiling

An autoclave's effectiveness comes from its ability to harness the physics of steam under pressure. This is the fundamental principle that enables its wide range of applications.

How It Works

Water normally boils at 100°C (212°F), a temperature insufficient to kill all microorganisms, especially resilient bacterial spores. By sealing a chamber and forcing in steam, an autoclave increases the internal pressure. This elevated pressure allows the steam to reach temperatures of 121°C or higher, which can denature proteins and destroy all forms of microbial life.

Key Components Enabling the Process

Several components work in unison to create this controlled, high-lethality environment.

- The pressure chamber is the core vessel where items are placed.

- A locking lid or door creates the essential airtight seal.

- A steam generator or electrical heater boils water to produce the required steam.

- Gauges and valves, including a critical safety valve, monitor and control the internal pressure and temperature.

Primary Applications Across Industries

The ability to achieve absolute sterility makes the autoclave a cornerstone technology in any field where microbial contamination is a critical concern.

Healthcare and Medicine

In hospitals, clinics, and even tattoo parlors, an autoclave is the gold standard for preventing infection. It is used to sterilize surgical instruments, reusable medical devices, and other equipment that comes into contact with patients. It is also used to decontaminate and render medical waste biologically safe before disposal.

Laboratory and Research

For microbiologists and researchers, preventing cross-contamination is paramount to achieving valid results. Autoclaves are used daily to sterilize laboratory glassware, solutions, and the culture media used to grow microorganisms. They are also used as a final step to decontaminate used media and equipment before cleaning or disposal.

Pharmaceutical Manufacturing

The purity of pharmaceutical products is non-negotiable. Autoclaves are used to sterilize drug packaging materials, containers, and various components used in the manufacturing process. This ensures that the final product is free from any microbial contamination that could harm a patient.

Food and Chemical Industries

In the food industry, a heavy-duty autoclave, often called a retort, is used to sterilize canned and jarred foods. This process kills spoilage-causing microbes, dramatically extending the product's shelf life and ensuring it is safe for consumption. Similar principles apply in chemical manufacturing for processes requiring high pressure and temperature.

Understanding the Critical Factors

While powerful, an autoclave's effectiveness is entirely dependent on correct operation. Missteps can lead to incomplete sterilization, nullifying the entire purpose of the process.

Material Compatibility is Non-Negotiable

Only heat- and moisture-resistant materials can be autoclaved. Certain plastics will melt, paper products can degrade, and some liquids are not stable at high temperatures. Using the wrong material can destroy the item and compromise the autoclave itself.

The Importance of Proper Loading

Steam must be able to circulate freely and contact every surface of the items being sterilized. Overloading the chamber or packing items too tightly creates air pockets and cool spots where steam cannot penetrate, leaving microorganisms alive.

Time is a Critical Parameter

Sterilization is a function of temperature, pressure, and time. A typical cycle runs at 121°C for at least 15-20 minutes, but this can vary based on the size and type of the load. Cutting a cycle short, even by a few minutes, can result in failed sterilization.

Making the Right Choice for Your Goal

Your specific objective dictates how you should approach using an autoclave, as the standard for "clean" varies by application.

- If your primary focus is preventing infection in a clinical setting: Your priority is the validated sterilization of instruments and the safe decontamination of all biological waste.

- If your primary focus is ensuring experimental integrity in a lab: You must guarantee the absolute sterility of culture media and glassware to prevent contamination from invalidating your research.

- If your primary focus is product safety in manufacturing: You must use the autoclave to ensure the purity and shelf-life of products, from pharmaceutical vials to canned goods.

Ultimately, mastering the autoclave's application is about understanding that complete sterilization is the non-negotiable standard for safety and validity in any critical environment.

Summary Table:

| Application | Key Use Case |

|---|---|

| Healthcare | Sterilizing surgical instruments and decontaminating medical waste. |

| Laboratory & Research | Sterilizing glassware, culture media, and decontaminating materials. |

| Pharmaceutical Manufacturing | Ensuring purity of drug packaging and components. |

| Food & Chemical Industry | Processing canned foods and materials requiring high-pressure sterilization. |

Ensure absolute sterility and safety in your operations with KINTEK's reliable autoclaves. Whether you're in a hospital, research lab, or manufacturing facility, our precision lab equipment is designed to meet rigorous sterilization standards. Contact us today to find the perfect autoclave solution for your needs!

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What is the necessity of using an autoclave for pre-treating culture media? Ensure Accurate Ag2O/TiO2 Testing

- Why is the standard autoclave temperature set to 121? The Science of Effective Sterilization

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization