In short, the hazards of evaporators are rooted in their core function: using thermal energy to change a liquid's phase under specific pressure conditions. This process inherently creates risks of chemical exposure from leaks, severe thermal burns from hot or cryogenic surfaces, and catastrophic failure from over-pressurization or vacuum collapse. Secondary risks include mechanical failures and hazards related to the specific materials being processed.

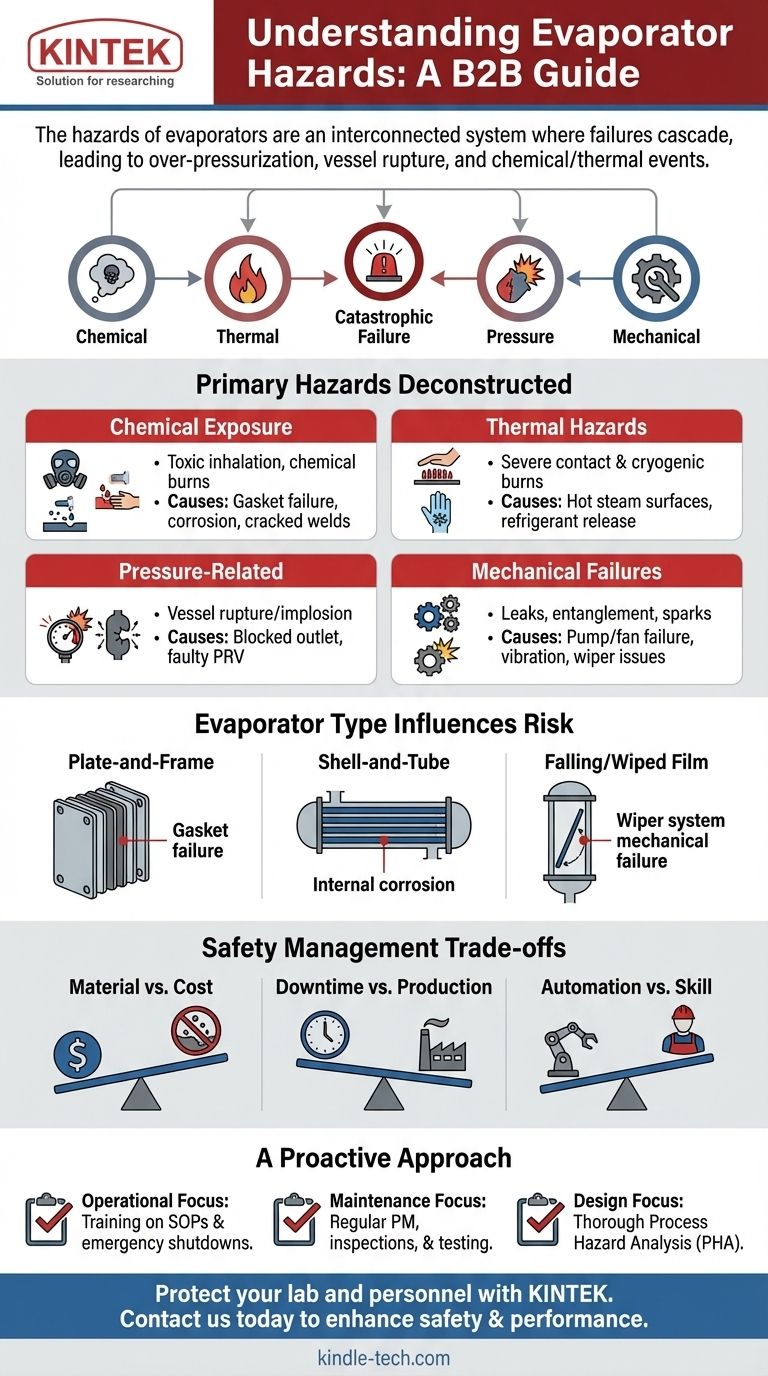

The central challenge with evaporator safety is not just knowing the individual hazards, but understanding them as an interconnected system. A failure in one area—such as a blocked outlet—can cascade, leading to over-pressurization, a vessel rupture, and a massive chemical and thermal event.

Deconstructing the Primary Hazards

An evaporator is a point of intense energy and material transformation. Understanding the risks begins with breaking them down into four primary categories.

H3: Chemical Exposure and Toxicity

The most immediate risk is the loss of containment of the process fluid or refrigerant. A leak can release hazardous materials into the workspace.

This can happen through failed gaskets, cracked welds, or corrosion-induced holes. The consequences range from toxic vapor inhalation (e.g., ammonia refrigerant) to severe chemical burns from contact with acids or caustics.

H3: Thermal Hazards (Burns)

Evaporators operate at temperature extremes. The heating medium, often high-pressure steam, means surfaces can be hot enough to cause immediate and severe contact burns.

Conversely, the refrigerant side can present cryogenic hazards. Accidental release of a liquefied refrigerant can flash-freeze tissue, causing deep cryogenic burns that are exceptionally damaging.

H3: Pressure-Related Risks

This is arguably the most dangerous hazard. If an evaporator's outlet is blocked while the heat source remains active, pressure will build rapidly, turning the vessel into a bomb. This is known as over-pressurization.

Without a properly sized and functioning pressure relief valve (PRV), the vessel can rupture violently. A less common but still serious risk is implosion, which can occur if a vessel under deep vacuum is not designed to withstand external atmospheric pressure.

H3: Mechanical Failures

Many evaporator systems include rotating equipment like pumps, fans, or agitators (in wiped-film evaporators). These parts present entanglement and crush hazards if not properly guarded.

Furthermore, vibration from pumps or poor structural support can lead to fatigue, causing pipes to crack and leak over time.

How Evaporator Type Influences Risk

The specific design of an evaporator directly influences its most likely failure points.

H3: Plate-and-Frame Evaporators

These units consist of many thin plates sealed by gaskets. The primary risk here is gasket failure. Age, chemical incompatibility, or improper tightening can lead to leaks, which are often the first sign of a problem.

H3: Shell-and-Tube Evaporators

In these common units, one fluid flows through tubes while another flows over them in a large shell. Internal corrosion of the tubes is a major concern, as it can lead to a pinhole leak that contaminates the other process stream or releases material to the atmosphere. Failure of the tube-to-tubesheet weld is another critical risk point.

H3: Falling or Wiped Film Evaporators

These are used for viscous or heat-sensitive products. The key additional hazard is the internal rotating wiper system. Mechanical failure of the wipers, bearings, or drive system can halt operation or, in a worst-case scenario, generate sparks in a flammable environment.

Understanding the Trade-offs in Safety Management

Effective safety is not just about following rules; it's about making informed decisions where resources and priorities compete.

H3: Material Selection vs. Upfront Cost

Choosing a lower-cost material of construction, like carbon steel instead of stainless steel or a higher-grade alloy, can save money initially. However, if that material is not fully compatible with the process fluid, it will lead to accelerated corrosion, drastically increasing the long-term risk of leaks and catastrophic failure.

H3: Maintenance Downtime vs. Production Goals

There is constant pressure to maximize uptime. Deferring scheduled maintenance, such as internal inspections or pressure relief valve testing, to meet production targets is a dangerous trade-off. It allows undiscovered problems like corrosion or fouling to worsen until they result in an unplanned, and potentially hazardous, failure.

H3: Process Automation vs. Operator Skill

Automated safety systems can react faster than a human and prevent common errors. However, an over-reliance on automation without robust operator training creates its own risk. If sensors fail or the system enters an unexpected state, a skilled operator who understands the process fundamentals is the last and most critical line of defense.

A Proactive Approach to Evaporator Safety

Managing evaporator hazards requires a proactive strategy that integrates design, maintenance, and operations. Your focus will determine your most critical actions.

- If your primary focus is operational safety: Prioritize comprehensive operator training on Standard Operating Procedures (SOPs), emergency shutdowns, and the fundamental physics of the system they are running.

- If your primary focus is maintenance and reliability: Implement a rigorous Preventive Maintenance (PM) program that includes regular inspection of pressure relief devices, ultrasonic thickness testing for corrosion, and detailed record-keeping.

- If your primary focus is system design or modification: Insist on a thorough Process Hazard Analysis (PHA) to identify risks and ensure that safety systems, materials of construction, and operational limits are appropriate for the service.

Ultimately, safety is not a static checklist but a dynamic process of managing energy and materials with vigilance and expertise.

Summary Table:

| Hazard Category | Key Risks | Common Causes |

|---|---|---|

| Chemical Exposure | Toxic inhalation, chemical burns | Gasket failure, corrosion, cracked welds |

| Thermal Hazards | Severe contact burns, cryogenic burns | Hot surfaces (steam), refrigerant release |

| Pressure-Related | Vessel rupture (explosion/implosion) | Blocked outlet, faulty pressure relief valve |

| Mechanical Failures | Leaks, entanglement, sparks | Pump/fan failure, vibration, wiper system issues |

Protect your lab and personnel from evaporator hazards. KINTEK specializes in lab equipment and consumables, providing reliable evaporators and expert support to ensure your processes are safe and efficient. Our solutions help you manage chemical, thermal, and pressure risks effectively. Contact us today to enhance your lab's safety and performance!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

People Also Ask

- Why is a freeze dryer preferred for reduced graphene oxide (Hh-RGO) powders? Preserve Nano-Structure and Performance

- What is the purpose of a freeze dryer? Preserve Sensitive Materials with Gentle Lyophilization

- What is freeze drying and how does it work? A Complete Guide to Lyophilization

- What is the key takeaway when selecting a lab freeze dryer? Let Your Sample's Needs Guide Your Choice

- What is collapse in freeze drying? A Critical Failure Event Explained