While the autoclave is a cornerstone of sterilization, its effectiveness is fundamentally tied to its use of high-temperature steam. This reliance means it is inherently unsuitable for any materials that are sensitive to heat or moisture, including certain plastics, sharp carbon steel instruments, delicate chemical solutions, and non-aqueous substances like oils and powders.

The very principle that makes autoclaving effective—high-pressure, high-temperature steam—is also its greatest constraint. Understanding this core trade-off between potent sterilization and material compatibility is essential for selecting the correct method and preventing irreversible damage to valuable items.

The Principle of Autoclaving: Why It Works (and When It Fails)

The Power of Moist Heat

An autoclave works by using steam under pressure to achieve temperatures high enough (typically 121°C or higher) to kill all microorganisms, including resilient bacterial spores.

This moist heat is highly efficient at denaturing the essential proteins and enzymes that microbes need to survive, ensuring thorough sterilization.

The Non-Negotiable Requirement: Water

The entire process depends on steam penetrating and transferring heat to the items being sterilized. Without water, this mechanism fails.

This is why an autoclave is the ideal method for sterilizing aqueous solutions like microbial growth media, but completely ineffective for substances that do not mix with water.

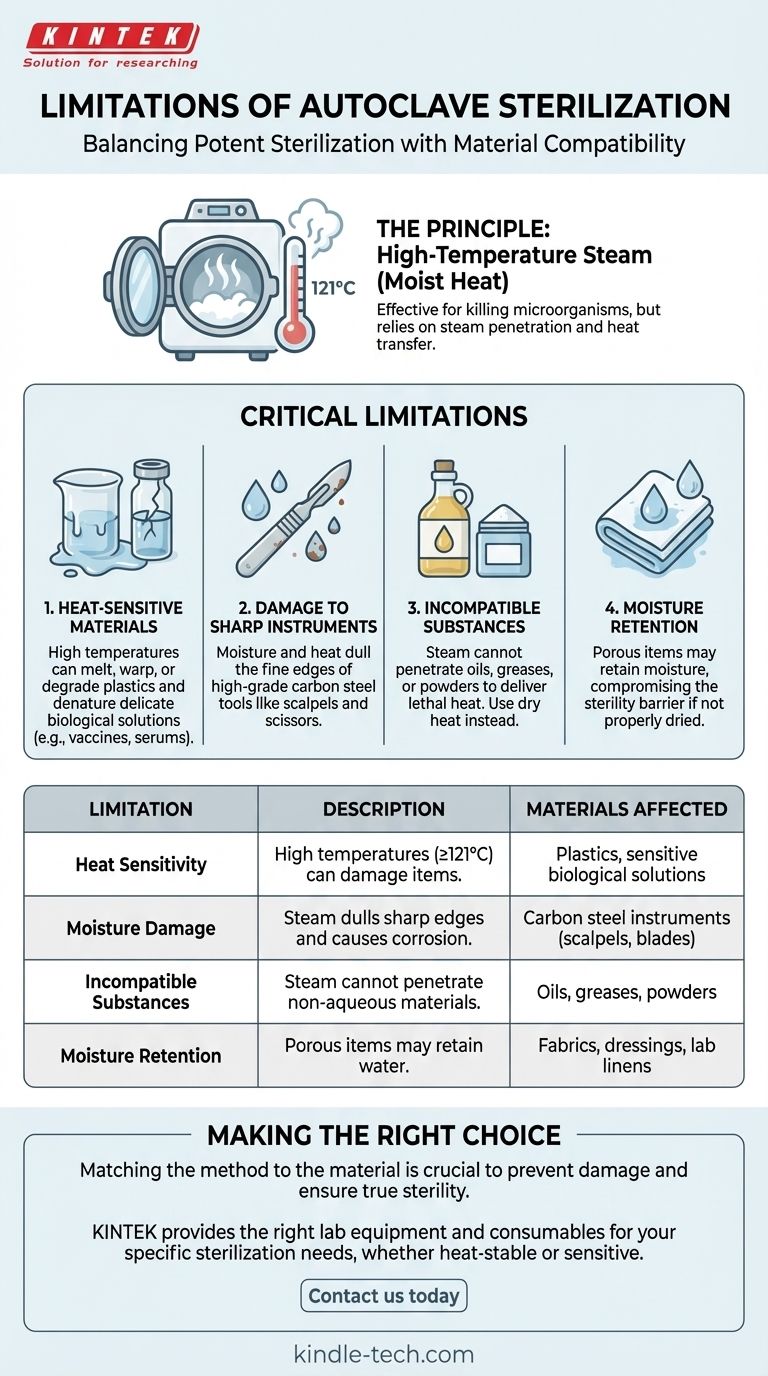

Critical Limitations of Autoclave Sterilization

Heat-Sensitive Materials

Many materials cannot withstand the high temperatures inside an autoclave. This is the most common and significant limitation.

Certain types of plasticware will melt, warp, or degrade. Sensitive biological solutions, such as some vaccines, serums, or proteins, will be denatured and rendered useless by the intense heat.

Damage to Sharp Instruments

While stainless steel surgical tools are routinely autoclaved, high-grade carbon steel instruments are not.

The combination of high heat and moisture will dull the fine cutting edge of scalpels, high-quality scissors, and blades, compromising their function.

Incompatibility with Anhydrous Materials

An autoclave cannot sterilize oils, greases, or powders. Steam cannot effectively penetrate these substances to deliver the lethal heat required.

Attempting to sterilize these materials in an autoclave will result in non-sterile items, as the heat transfer is insufficient. For these applications, dry heat sterilization is the appropriate method.

Risk of Moisture Retention

Porous items like fabrics, dressings, or some lab linens can retain significant moisture after an autoclave cycle.

If not properly dried, this residual moisture can compromise the sterility barrier or interfere with the intended application of the item.

Understanding the Trade-offs: Efficacy vs. Material Damage

Advantage: Unmatched Efficacy for Tolerant Items

For materials that can withstand the conditions—such as glassware, stainless steel instruments, and stable aqueous media—the autoclave is exceptionally effective.

It is economical, relatively fast, and the steam provides excellent penetration on all surfaces of suitable items, requiring no harsh chemicals.

Disadvantage: The Cost of Incompatibility

Using an autoclave on an incompatible item is not just ineffective; it is often destructive. The cost of replacing melted equipment, dulled instruments, or degraded chemical reagents far outweighs any perceived convenience.

The Myth of Pressure

A common misunderstanding is that pressure itself kills microorganisms. In reality, pressure is simply the tool used to raise the temperature of steam above the normal boiling point of water.

It is the high temperature (e.g., 121°C) of the moist heat that performs the sterilization, not the pressure (e.g., 15 psi).

Making the Right Choice for Your Goal

Before selecting a sterilization method, you must first evaluate the material you are working with.

- If your primary focus is sterilizing heat-stable items like glassware, surgical steel, or microbial media: The autoclave is your most economical and effective choice.

- If your primary focus is working with heat-sensitive plastics, electronics, or delicate chemical solutions: You must explore low-temperature alternatives like ethylene oxide (EtO), hydrogen peroxide plasma, or sterile filtration.

- If your primary focus is preserving the edge of sharp carbon steel instruments: Consider dry heat sterilization or other validated methods that avoid moisture and high temperatures.

- If your primary focus is handling oils, powders, or other anhydrous materials: Dry heat sterilization is the correct and necessary method, as steam will not penetrate these substances.

Matching the sterilization method to the material is the fundamental principle of achieving true sterility without causing damage.

Summary Table:

| Limitation | Description | Materials Affected |

|---|---|---|

| Heat Sensitivity | High temperatures (≥121°C) can melt, warp, or degrade items. | Plastics, sensitive biological solutions |

| Moisture Damage | Steam can dull sharp edges and cause corrosion. | Carbon steel instruments (scalpels, blades) |

| Incompatible Substances | Steam cannot penetrate or effectively sterilize non-aqueous materials. | Oils, greases, powders |

| Moisture Retention | Porous items may retain water, compromising sterility. | Fabrics, dressings, lab linens |

Are you using the right sterilization method for your lab equipment?

Using an autoclave on incompatible materials can lead to irreversible damage, costly replacements, and compromised sterility. KINTEK specializes in providing the right lab equipment and consumables for your specific sterilization needs, whether you require autoclaves for heat-stable items or alternative solutions for sensitive materials.

Let our experts help you protect your investment and ensure effective sterilization. Contact us today for a personalized consultation!

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What is the function of a circulating loop system with a Hastelloy autoclave? Enhance PWR Corrosion Research Accuracy

- What are the three advantages of the steam autoclave? Unmatched Speed, Cost-Effectiveness & Safety

- What is the temperature of autoclave 121? Mastering Pressure, Steam & Sterilization Time

- What is the primary role of high-pressure high-temperature autoclaves in SCWR research? Key Roles in Material Validation

- What is the function and limitation of chemical indicators in autoclave monitoring? Essential Sterilization Workflow Guide

- How often do autoclaves need to be serviced? A Guide to Risk-Based Maintenance Schedules

- How long does autoclaving take? Mastering Sterilization Times for Your Lab

- Is a sterilizer an autoclave? Understand the Key Differences for Your Lab