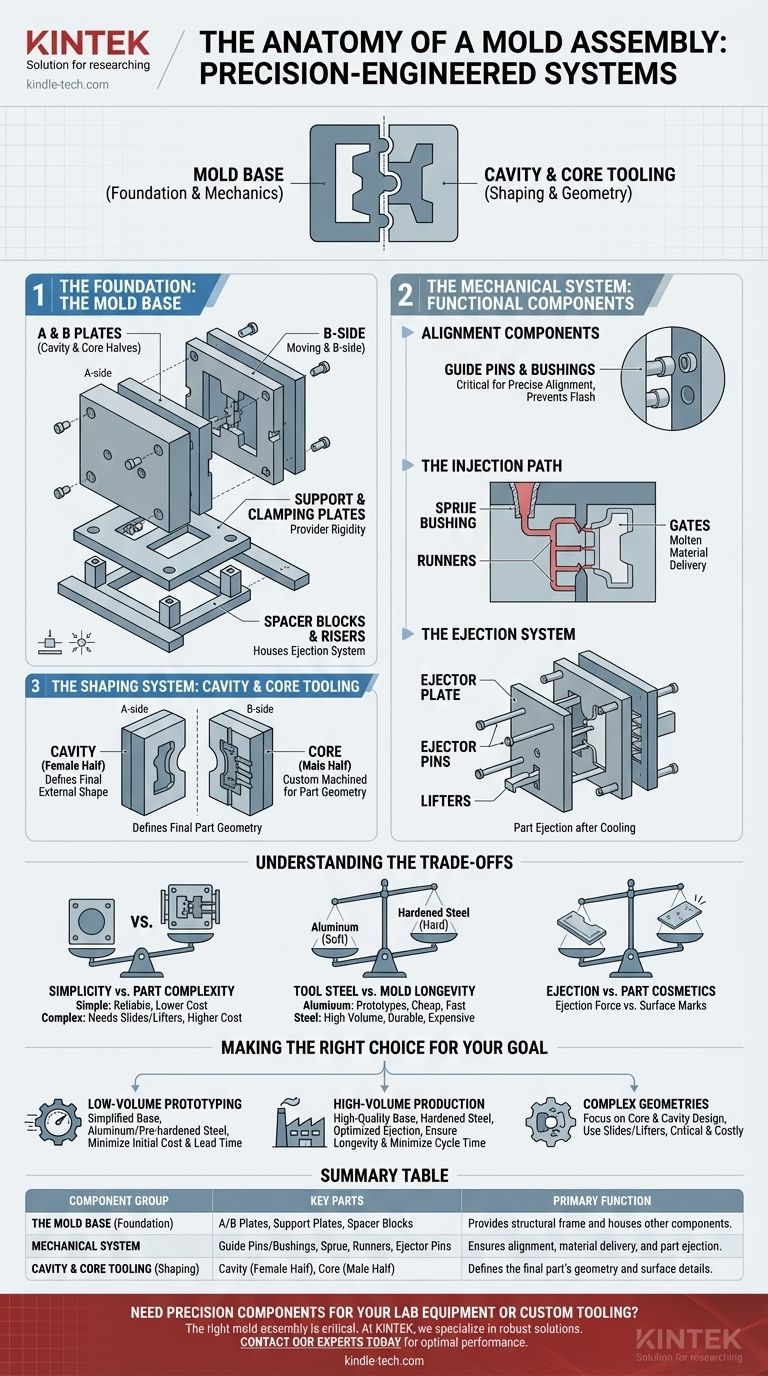

At its core, a mold assembly is a precision-engineered system of interlocking parts designed to shape molten material into a final product. While a simple mold might just be two halves, a production mold is comprised of three distinct functional groups: the frame plates that hold everything together, the mechanical components that guide and actuate the mold, and the cavity tooling that directly forms the part.

A mold is best understood as two primary systems working in concert. The Mold Base provides the structural frame and mechanical action, while the Cavity and Core Tooling are the custom-machined components that define the final part's geometry.

The Foundation: The Mold Base

The mold base is the standardized frame or chassis of the entire assembly. It provides the structural integrity, alignment, and mounting points for all other components.

A and B Plates (Cavity and Core Halves)

The entire mold is split into two halves. The A-side, or cavity half, typically remains stationary and is where the plastic or other material is injected. The B-side, or core half, is the moving half that contains the system for ejecting the finished part.

Support and Clamping Plates

These plates provide rigidity to the core and cavity inserts, preventing them from flexing under the immense pressure of injection. Clamping plates are the outermost plates used to secure the mold assembly into the molding machine.

Spacer Blocks and Risers

Spacer blocks create a gap within the B-side of the mold base. This space is essential as it houses the entire ejection system, allowing it to move forward and push the part out of the mold.

The Mechanical System: Functional Components

These are the active parts of the mold that ensure precise alignment, material delivery, and part ejection cycle after cycle.

Alignment Components

Guide pins and bushings are the most critical alignment components. These hardened steel pins on one half of the mold mate perfectly with bushings on the other, ensuring the cavity and core align with extreme precision every time the mold closes. Misalignment results in defects like "flash."

The Injection Path

The sprue bushing is the entry point for the molten material from the machine's nozzle. From there, the material travels through channels known as runners to reach the gates, which are the specific openings into the part cavity itself.

The Ejection System

Once the part is cooled and solidified, the ejector system activates. A plate pushes a series of ejector pins forward, which press against the part to push it out of the core half of the mold. For more complex features, lifters or sleeves may be used to eject the part without damage.

The Shaping System: Cavity and Core Tooling

This is the "custom" part of the mold. While the mold base is often standardized, the cavity and core are uniquely machined to create the specific geometry of the desired part.

The Cavity

The cavity is the machined pocket, typically in the A-side of the mold, that forms the external surfaces of the molded part. It is often referred to as the female half of the tool.

The Core

The core is the machined protrusion, typically in the B-side, that forms the internal surfaces of the part. It is the male half of the tool that fits inside the cavity when the mold is closed.

Understanding the Trade-offs

Designing a mold assembly is a series of engineering compromises between cost, complexity, and performance.

Simplicity vs. Part Complexity

A simple "open-and-shut" mold with no moving parts besides the ejector system is reliable and cost-effective. However, to create parts with undercuts or side features, complex mechanisms like slides or lifters are required, significantly increasing the mold's cost and maintenance requirements.

Tool Steel vs. Mold Longevity

The type of steel used for the core and cavity is a critical decision. Softer steels like aluminum are cheap and easy to machine, making them ideal for prototypes. Hardened tool steels are much more expensive and difficult to machine but can withstand millions of production cycles without wear.

Ejection vs. Part Cosmetics

The placement and size of ejector pins are a constant balance. You need enough force and surface area to eject the part cleanly without warping it, but every ejector pin will leave a small, often undesirable, circular mark on the final part's surface.

Making the Right Choice for Your Goal

The composition of your mold assembly should directly reflect your project's objective.

- If your primary focus is low-volume prototyping: Opt for a simplified mold base, potentially made from aluminum or pre-hardened steel, to minimize initial cost and lead time.

- If your primary focus is high-volume production: Invest in a high-quality mold base with hardened steel components, superior cooling channels, and an optimized ejection system to ensure longevity and minimize cycle time.

- If your primary focus is creating complex geometries: The design of the core and cavity, along with any necessary slides and lifters, will be the most critical and costly part of the assembly.

Understanding how these individual components function as a complete system is the key to designing, troubleshooting, and producing quality molded parts.

Summary Table:

| Mold Assembly Component Group | Key Parts | Primary Function |

|---|---|---|

| The Mold Base (Foundation) | A/B Plates, Support Plates, Spacer Blocks | Provides structural frame and houses other components. |

| Mechanical System | Guide Pins/Bushings, Sprue Bushing, Runners, Ejector Pins | Ensures alignment, material delivery, and part ejection. |

| Cavity & Core Tooling (Shaping) | Cavity (Female Half), Core (Male Half) | Defines the final part's geometry and surface details. |

Need precision components for your lab equipment or custom tooling? The right mold assembly is critical for producing reliable, high-quality parts. At KINTEK, we specialize in supplying robust lab equipment and consumables. Our expertise can help you select or develop the ideal tooling solutions for your specific laboratory applications, whether for prototyping or high-volume production. Contact our experts today to discuss your project requirements and ensure optimal performance.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for Acid and Alkali Resistant Chemical Powder Material Scoops

- Custom Boron Nitride (BN) Ceramic Parts

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Custom PTFE Teflon Parts Manufacturer for Cleaning Racks

People Also Ask

- How does compression molding affect the environment? A Guide to Sustainable Manufacturing

- What are the functions of high-purity graphite molds in SPS? Essential Roles in Spark Plasma Sintering

- What advantages do standardized laboratory compression-cell molds provide for c-LLZO? Optimize Battery Data Accuracy

- What are the different types of compression molding? BMC vs. SMC and Mold Design Explained

- Why is it necessary to use pressure-maintaining dies or fixtures? Ensure Solid-State Battery Interface Stability

- What is the function of graphite molds in SPS for LLZT? Maximize Conductivity and Pressure for Solid Electrolytes

- What is the use of potassium bromide in IR? Achieve Clear Solid Sample Analysis with KBr Pellets

- What is the difference between injection mold and insert mold? A Guide to Multi-Material Parts