At its core, the steam autoclave's primary advantages are its unmatched speed, profound cost-effectiveness, and non-toxic operation. It leverages the simple physics of pressurized steam to achieve rapid and complete microbial destruction, making it a cornerstone of sterilization in medical, laboratory, and industrial settings for over a century.

The true power of the autoclave lies not just in its heat, but in its use of moist heat under pressure. This combination allows it to transfer lethal energy into microorganisms far more efficiently than dry heat, ensuring reliable and rapid sterilization without relying on harsh chemicals.

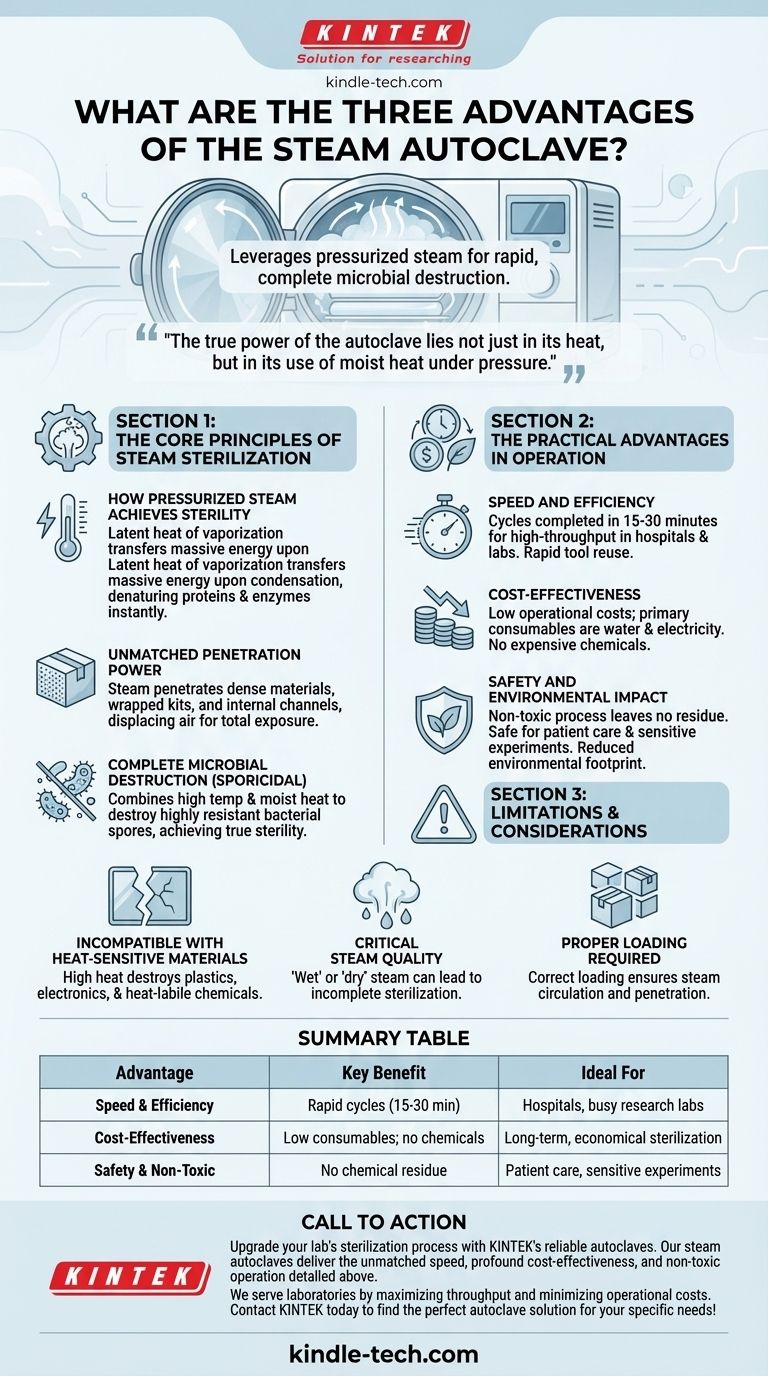

The Core Principles of Steam Sterilization

To understand the autoclave's advantages, you must first understand its mechanism. It is not simply a high-temperature oven; it is a precisely engineered system designed to harness the unique properties of steam.

How Pressurized Steam Achieves Sterility

The key is latent heat of vaporization. When steam condenses on a cooler surface (like a surgical instrument or lab glassware), it rapidly transfers a massive amount of energy.

This energy transfer instantly and irreversibly denatures the essential proteins and enzymes that microorganisms, including resilient bacterial spores, need to survive. This process is far more efficient and rapid than simply baking them with dry heat.

Unmatched Penetration Power

Unlike surface-level sterilization methods like UV light, steam can effectively penetrate dense materials. This includes wrapped surgical kits, porous fabrics, and the internal channels of complex instruments.

As steam fills the chamber under pressure, it displaces air and ensures that every surface, nook, and cranny is exposed to the sterilizing agent.

Complete Microbial Destruction (Sporicidal)

A key distinction of autoclaving is its sporicidal capability. Many disinfection methods can kill active bacteria, but they fail to eliminate highly resistant bacterial spores.

The combination of high temperature and moist heat delivered by an autoclave is one of the most reliable and validated methods for destroying these spores, achieving a true state of sterility.

The Practical Advantages in Operation

The scientific principles translate directly into tangible benefits for any professional environment requiring sterile equipment.

Speed and Efficiency

Autoclave cycles are remarkably fast, often completed in 15 to 30 minutes, depending on the load size and type. This rapid turnover is critical for high-throughput environments like hospitals and busy research labs, allowing for the efficient reuse of essential tools.

Cost-Effectiveness

The operational costs of an autoclave are exceptionally low. The primary consumables are deionized water and electricity. There are no expensive proprietary chemicals to purchase or hazardous waste to dispose of, making it a highly economical choice for long-term use.

Safety and Environmental Impact

Steam sterilization is a fundamentally non-toxic process. It leaves behind no chemical residue on the sterilized items, ensuring they are safe for immediate use in patient care or sensitive experiments. This eliminates risks of chemical exposure for operators and reduces the facility's environmental footprint.

Understanding the Limitations and Requirements

While dominant, the steam autoclave is not a universal solution. Its effectiveness is contingent on proper use and an understanding of its limitations.

Incompatibility with Heat-Sensitive Materials

The primary drawback is its reliance on high heat (typically 121°C or 134°C). This process will destroy or damage many plastics, heat-labile chemicals, and delicate electronic instruments. For these items, alternative low-temperature sterilization methods are required.

The Critical Role of Steam Quality

Sterilization can fail if the steam is not of the proper quality. "Wet" steam (too much water content) can leave items damp and prone to recontamination. "Dry" steam or the presence of non-condensable gases (like air) can create cold spots and prevent proper energy transfer, leading to incomplete sterilization.

The Need for Proper Loading

Items must be loaded into the autoclave in a way that allows for steam circulation and penetration. Over-packing the chamber or using improper containers can block steam from reaching all surfaces, rendering the cycle ineffective.

Making the Right Choice for Your Application

Selecting the right sterilization method depends entirely on the material you are processing and your operational goals.

- If your primary focus is high-throughput, cost-effective sterilization of heat-stable items: The steam autoclave is the undisputed gold standard for its speed, reliability, and low operating cost.

- If your primary focus is sterilizing heat-sensitive plastics, electronics, or delicate instruments: The autoclave is unsuitable, and you must explore low-temperature alternatives like ethylene oxide (EtO) or hydrogen peroxide gas plasma.

- If your primary focus is ensuring the highest level of microbial and sporicidal kill for durable goods: A properly validated and operated steam autoclave provides one of the most trusted and effective methods available.

Ultimately, the steam autoclave remains the workhorse of sterilization because it provides a rapid, reliable, and economical solution for the vast majority of reprocessing needs.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Speed & Efficiency | Rapid cycles (15-30 min) for high-throughput | Hospitals, busy research labs |

| Cost-Effectiveness | Low consumables (water, electricity); no chemicals | Long-term, economical sterilization |

| Safety & Non-Toxic | No chemical residue; safe for immediate use | Patient care, sensitive experiments |

Upgrade your lab's sterilization process with KINTEK's reliable autoclaves.

Our steam autoclaves are engineered to deliver the unmatched speed, profound cost-effectiveness, and non-toxic operation detailed above, ensuring your medical, laboratory, or industrial facility achieves the highest standard of sterility efficiently and safely.

We serve laboratories by providing robust equipment that maximizes throughput and minimizes operational costs. Let KINTEK be your trusted partner in creating a safer, more efficient workspace.

Contact KINTEK today to find the perfect autoclave solution for your specific needs!

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- What is the 121 cycle of autoclave? A Guide to Guaranteed Sterilization

- Why is proper maintenance and cleaning of the autoclave important? Ensure Sterilization Efficacy and Safety

- What precautions should be taken during autoclave in laboratory? A Complete Safety Guide to Prevent Burns and Explosions

- Why is it important to use the autoclave to sterilize laboratory tools? Ensure Complete Sterility for Reliable Results

- What are the do's and don'ts in using autoclave? A Guide to Safe and Effective Sterilization