At its core, the primary use of an autoclave in a medical laboratory is to achieve absolute sterilization. It uses high-pressure, superheated steam to eliminate all forms of microbial life—including bacteria, viruses, fungi, and highly resistant spores—from lab equipment, culture media, and biohazardous waste. This process is fundamental to ensuring experimental accuracy, preventing contamination, and maintaining a safe working environment.

An autoclave is not merely a cleaning device; it is the gold standard for sterilization. Its ability to destroy even the most resilient microorganisms makes it an indispensable tool for guaranteeing the integrity of microbiological work and the safe disposal of hazardous materials.

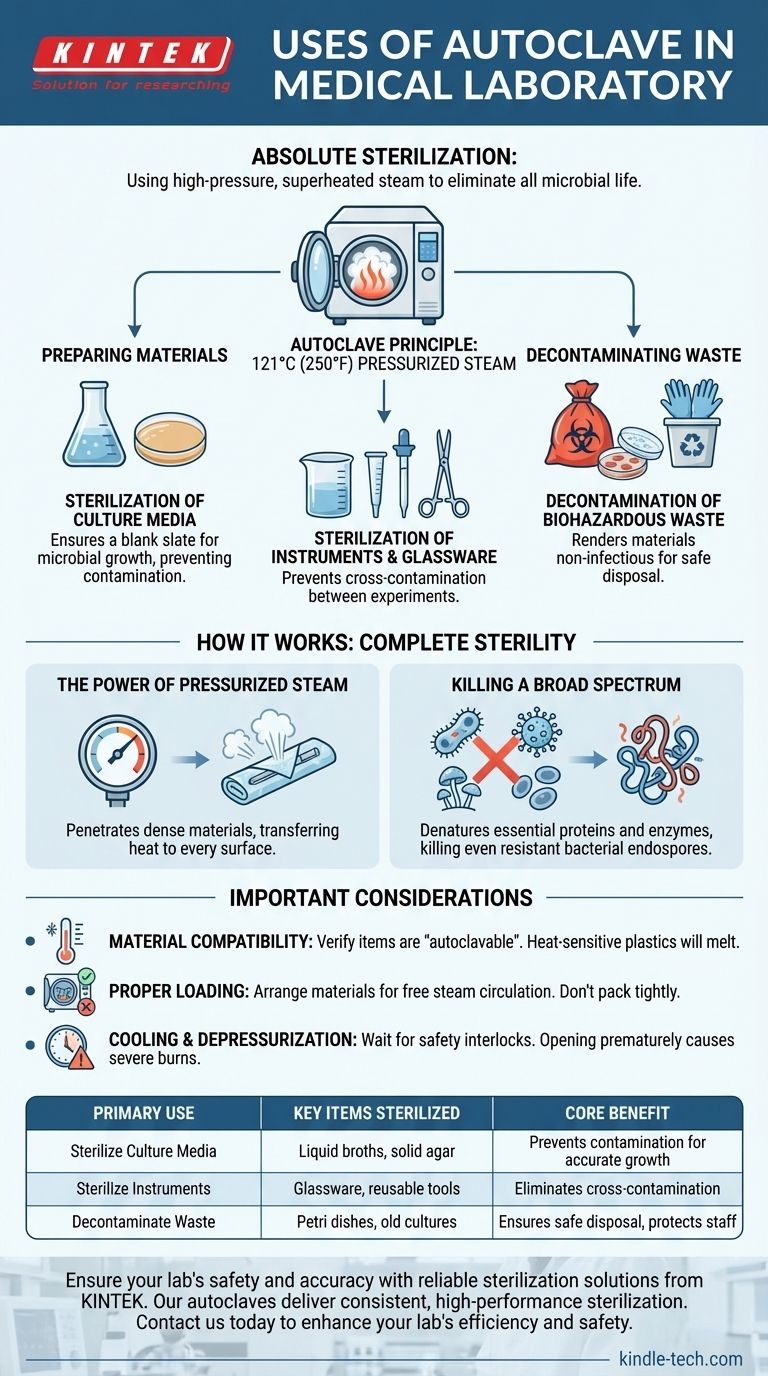

The Core Functions of a Medical Lab Autoclave

An autoclave's role in a medical lab can be broken down into three critical functions: preparing materials for use, decontaminating materials after use, and ensuring the sterility of reagents.

Sterilization of Culture Media

Before you can grow a specific microorganism, its food source, or culture medium, must be a completely blank slate. Autoclaves are used to sterilize both liquid broths and solid agar media before they are inoculated with a sample.

This step is non-negotiable, as any contaminating microbes in the media would lead to incorrect results, wasted resources, and potentially misidentified pathogens.

Sterilization of Instruments and Glassware

To prevent cross-contamination between experiments, all reusable lab equipment must be sterilized. This includes a wide range of items.

Commonly sterilized items include glassware like flasks and beakers, reusable pipette tips, and various metal and heat-resistant plastic instruments. This ensures that the only microbes present in an experiment are the ones you intentionally introduce.

Decontamination of Biohazardous Waste

Perhaps the most critical safety function of a lab autoclave is the decontamination of biological waste. Anything that has come into contact with microorganisms must be sterilized before it can be safely discarded.

This includes used petri dishes, contaminated plastic tubes, gloves, and old cultures. The autoclave renders these materials non-infectious, protecting laboratory staff and the environment from exposure to potentially pathogenic organisms.

How an Autoclave Achieves Complete Sterility

The effectiveness of an autoclave comes from a simple but powerful principle: combining intense heat with high pressure. This combination is far more effective than simple boiling or chemical disinfectants.

The Power of Pressurized Steam

An autoclave functions like a sophisticated pressure cooker. By increasing the pressure inside its chamber, it allows water to boil at a much higher temperature, typically 121°C (250°F).

This superheated steam can penetrate dense materials, fabrics, and the hollows of complex instruments, ensuring that heat is transferred to every surface.

Killing a Broad Spectrum of Microorganisms

The high-temperature, high-pressure environment denatures the essential proteins and enzymes that all microorganisms need to survive.

Crucially, this includes bacterial endospores, which are tough, dormant structures that can survive boiling, radiation, and many chemical disinfectants. The ability to reliably kill spores is what defines true sterilization and sets the autoclave apart from lesser methods of cleaning.

Understanding the Trade-offs and Limitations

While powerful, an autoclave is not a universal solution. Its effective and safe use requires an understanding of its limitations and the proper protocols.

Material Compatibility is Crucial

Not all materials can withstand the high heat and pressure of an autoclave. Heat-sensitive plastics will melt, certain sharp instruments can become dulled, and some chemical solutions may degrade or become volatile.

Always verify that an item is "autoclavable" before placing it inside. Non-compatible materials can be destroyed and may even damage the autoclave itself.

Proper Loading and Operation are Non-Negotiable

Effective sterilization depends on steam reaching every surface. Improperly loading the autoclave by packing items too tightly can create air pockets that insulate microbes from the steam.

Materials must be arranged to allow for free steam circulation. Similarly, automatic cycles must be chosen correctly based on the load (e.g., liquids, solids, or waste) to ensure the proper time and temperature are applied.

The Importance of Cooling and Depressurization

After a cycle completes, the contents are still under high pressure and at an extremely high temperature. Attempting to open the door prematurely is incredibly dangerous and can cause severe steam burns or explosive boiling of liquids.

Modern autoclaves have safety interlocks that prevent the door from being opened until the pressure and temperature have returned to safe levels. This cool-down period is an essential part of the process.

Making the Right Choice for Your Goal

The autoclave is a versatile tool, but its specific application depends on your immediate objective in the laboratory workflow.

- If your primary focus is microbiological culture: Use the autoclave to create sterile media and prepare glassware, ensuring your experiment begins without any pre-existing contamination.

- If your primary focus is laboratory safety: Use the autoclave as the final step for all biohazardous materials, guaranteeing they are rendered non-infectious before disposal.

- If your primary focus is procedural accuracy: Sterilize all solutions, water, and reusable instruments to eliminate variables that could compromise the integrity and reproducibility of your results.

Ultimately, the autoclave serves as the cornerstone of sterile technique, providing the foundation of safety and reliability upon which all accurate medical laboratory work is built.

Summary Table:

| Primary Use | Key Items Sterilized | Core Benefit |

|---|---|---|

| Sterilize Culture Media | Liquid broths, solid agar | Prevents contamination for accurate microbial growth |

| Sterilize Instruments | Glassware, reusable tools | Eliminates cross-contamination between experiments |

| Decontaminate Waste | Petri dishes, old cultures, biohazardous materials | Ensures safe disposal and protects lab personnel |

Ensure your lab's safety and accuracy with reliable sterilization solutions from KINTEK.

As a leading provider of laboratory equipment and consumables, KINTEK understands the critical need for dependable autoclaves in medical and research settings. Our autoclaves are designed to deliver consistent, high-performance sterilization, helping you maintain contamination-free environments, protect your team from biohazards, and uphold the integrity of your results.

Whether you're preparing culture media, sterilizing instruments, or decontaminating waste, KINTEK has the right equipment to meet your lab's specific needs.

Contact us today to learn how our autoclave solutions can enhance your laboratory's efficiency and safety!

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

People Also Ask

- What instruments are used in autoclave sterilization? A Guide to Validating Sterility with Confidence

- Why is proper maintenance and cleaning of the autoclave important? Ensure Sterilization Efficacy and Safety

- How much time is required for autoclave sterilization of instruments? Understand the Full Cycle for Safety

- What is the size of the autoclave? Choose the Right Capacity for Your Lab

- What precautions should be taken during autoclave in laboratory? A Complete Safety Guide to Prevent Burns and Explosions