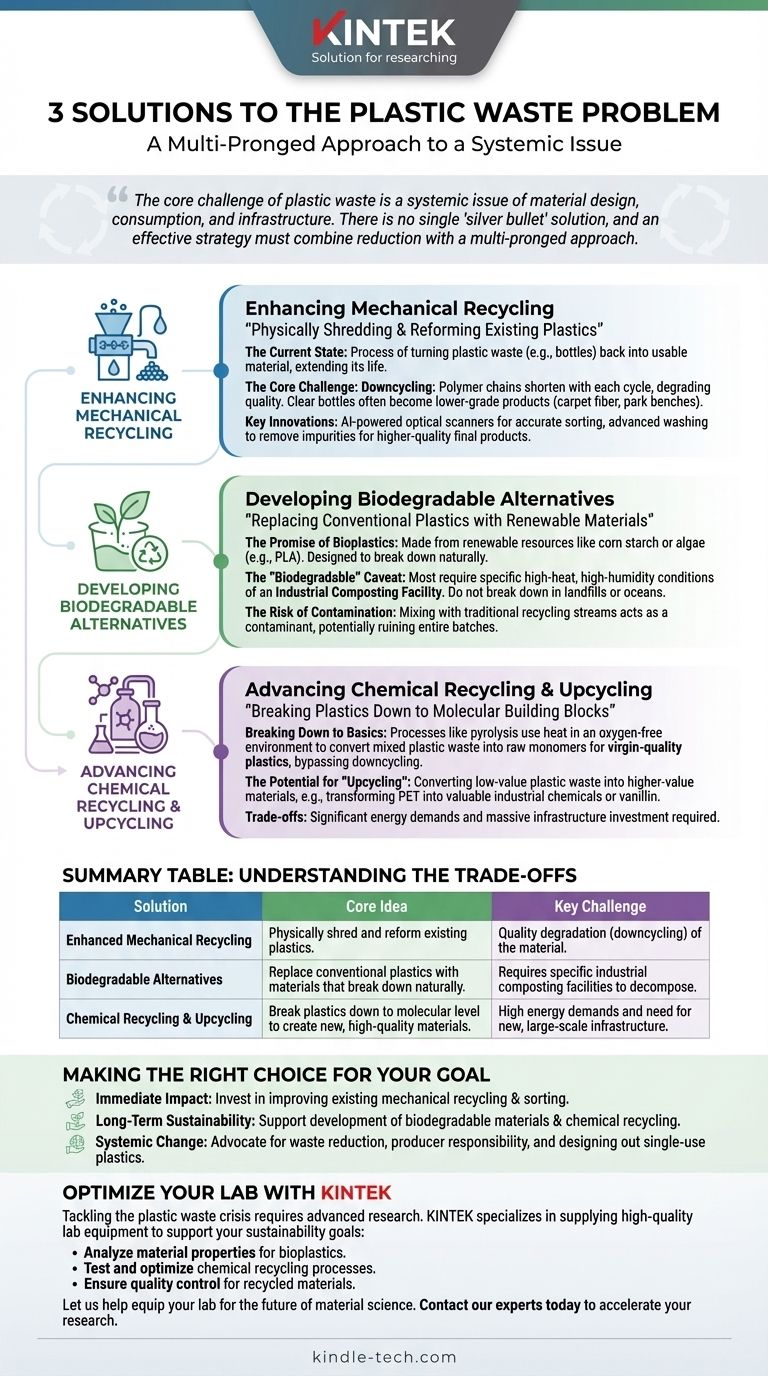

The three primary solutions to the plastic waste problem are enhancing traditional mechanical recycling, developing and scaling biodegradable alternatives, and advancing new forms of chemical recycling and upcycling. Each approach targets a different stage of the plastic lifecycle, from improving how we handle existing waste to fundamentally changing the materials we use.

The core challenge of plastic waste is not just about disposal; it's a systemic issue of material design, consumption, and infrastructure. There is no single "silver bullet" solution, and an effective strategy must combine reducing our overall consumption with a multi-pronged approach to managing the waste we cannot avoid.

Solution 1: Enhancing Mechanical Recycling

Mechanical recycling is the most established method for processing plastic waste. It involves physically shredding, washing, melting, and reforming plastic into new pellets for manufacturing.

The Current State of Mechanical Recycling

This is the process most people are familiar with—placing a plastic bottle into a recycling bin. The goal is to turn that bottle back into a usable material, extending its life and reducing the need for virgin plastic.

The Core Challenge: Downcycling

The primary limitation of mechanical recycling is downcycling. Each time plastic is melted and reprocessed, its polymer chains shorten, degrading its quality and strength. This means a clear water bottle rarely becomes another clear water bottle; it's more likely to become a lower-grade product like carpet fiber or a park bench.

Key Innovations for Improvement

To combat downcycling, efforts are focused on better sorting and cleaning. AI-powered optical scanners can identify and separate different types of plastics with far greater accuracy than human sorters, reducing contamination. Advanced washing processes can also remove more impurities, leading to a higher-quality final product.

Solution 2: Developing Biodegradable Alternatives

This approach focuses on replacing conventional, petroleum-based plastics with materials designed to break down naturally in the environment.

The Promise of Bioplastics

Bioplastics are made from renewable resources like corn starch, sugarcane, or algae. The most common example is Polylactic Acid (PLA), often used in disposable cups and food containers. The goal is to create materials that don't persist in the environment for centuries.

The "Biodegradable" Caveat

A critical distinction is that most "biodegradable" or "compostable" plastics do not break down in a landfill or the ocean. They require the specific high-heat, high-humidity conditions of an industrial composting facility, which are not yet widely available.

The Risk of Contamination

If bioplastics like PLA are mistakenly mixed into the traditional plastic recycling stream, they act as a contaminant. Because they have a different chemical makeup and melting point, they can ruin an entire batch of recycled petroleum-based plastic, highlighting the need for clear labeling and consumer education.

Solution 3: Advancing Chemical Recycling and Upcycling

Chemical recycling is an emerging set of technologies that uses chemical processes, heat, or catalysts to break plastics down into their original molecular building blocks.

Breaking Plastic Down to Basics

Processes like pyrolysis use high heat in an oxygen-free environment to convert mixed plastic waste back into a liquid oil or raw monomers. These raw materials can then be used to create new, virgin-quality plastics, completely bypassing the problem of downcycling.

The Potential for "Upcycling"

A more advanced concept is upcycling, which aims to convert low-value plastic waste into higher-value materials. For example, researchers are using engineered enzymes and chemical processes to transform PET (the plastic in water bottles) into valuable industrial chemicals or even vanillin, the primary component of vanilla flavor.

Understanding the Trade-offs

No single solution is perfect, and each comes with significant challenges that must be addressed for it to be effective at a global scale.

The Energy and Infrastructure Gap

Both advanced mechanical sorting and chemical recycling require significant energy and massive investment in new infrastructure. Furthermore, scaling biodegradable alternatives requires building a parallel system of industrial composting facilities to process them correctly.

The Root Cause: Overconsumption

Ultimately, recycling and material innovation only address the "end-of-life" part of the problem. Without a simultaneous and aggressive effort to reduce the production and consumption of single-use plastics, these solutions will struggle to keep pace with the sheer volume of waste being generated.

Making the Right Choice for Your Goal

The optimal path forward depends on combining these strategies to address different aspects of the plastic waste crisis.

- If your primary focus is immediate impact: Invest in improving existing mechanical recycling infrastructure and enforcing better public sorting practices to maximize the value of materials already in circulation.

- If your primary focus is long-term sustainability: Support the development and scaling of truly biodegradable materials and the chemical recycling technologies needed to create a fully circular plastic economy.

- If your primary focus is systemic change: Advocate for policies that prioritize waste reduction, hold producers responsible for the entire lifecycle of their products, and design out single-use plastics from the start.

A successful future depends on a multifaceted strategy that reduces our reliance on plastic, improves how we manage it, and innovates the very nature of our materials.

Summary Table:

| Solution | Core Idea | Key Challenge |

|---|---|---|

| Enhanced Mechanical Recycling | Physically shred and reform existing plastics. | Quality degradation (downcycling) of the material. |

| Biodegradable Alternatives | Replace conventional plastics with materials that break down naturally. | Requires specific industrial composting facilities to decompose. |

| Chemical Recycling & Upcycling | Break plastics down to molecular level to create new, high-quality materials. | High energy demands and need for new, large-scale infrastructure. |

Optimize Your Lab's Role in Material Innovation with KINTEK

Tackling the plastic waste crisis requires advanced research and precise material analysis. Whether you are developing new biodegradable polymers, optimizing recycling processes, or exploring chemical upcycling pathways, having the right laboratory equipment is crucial for success.

KINTEK specializes in supplying high-quality lab equipment and consumables to support your sustainability goals. We provide the tools you need to:

- Analyze material properties and degradation rates for bioplastics.

- Test and optimize chemical recycling and pyrolysis processes.

- Ensure quality control for recycled materials and new polymer formulations.

Let us help you equip your lab for the future of material science. Contact our experts today to discuss how our solutions can accelerate your research and contribute to a circular economy.

Visual Guide

Related Products

- Button Battery Storage Box for Battery Lab

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Custom PTFE Teflon Parts Manufacturer for Cleaning Racks

- Custom PTFE Teflon Parts Manufacturer for Acid and Alkali Resistant Chemical Powder Material Scoops

People Also Ask

- What handling precautions should be taken when storing an all-PTFE electrolytic cell? Prevent Permanent Deformation

- What is the importance of using an inert atmosphere glove box for all-solid-state lithium batteries? Secure Cell Safety

- Why is an argon glove box required for LTPO battery assembly? Ensure High-Purity Inert Environments for Li-Ion Research

- Why are PTFE materials specified for alkaline HER testing? Ensure High-Purity Catalyst Performance and Accuracy

- What is the function of PTFE linings in alkaline hydrolysis? Ensure Pure PET Recycling and Corrosion Protection