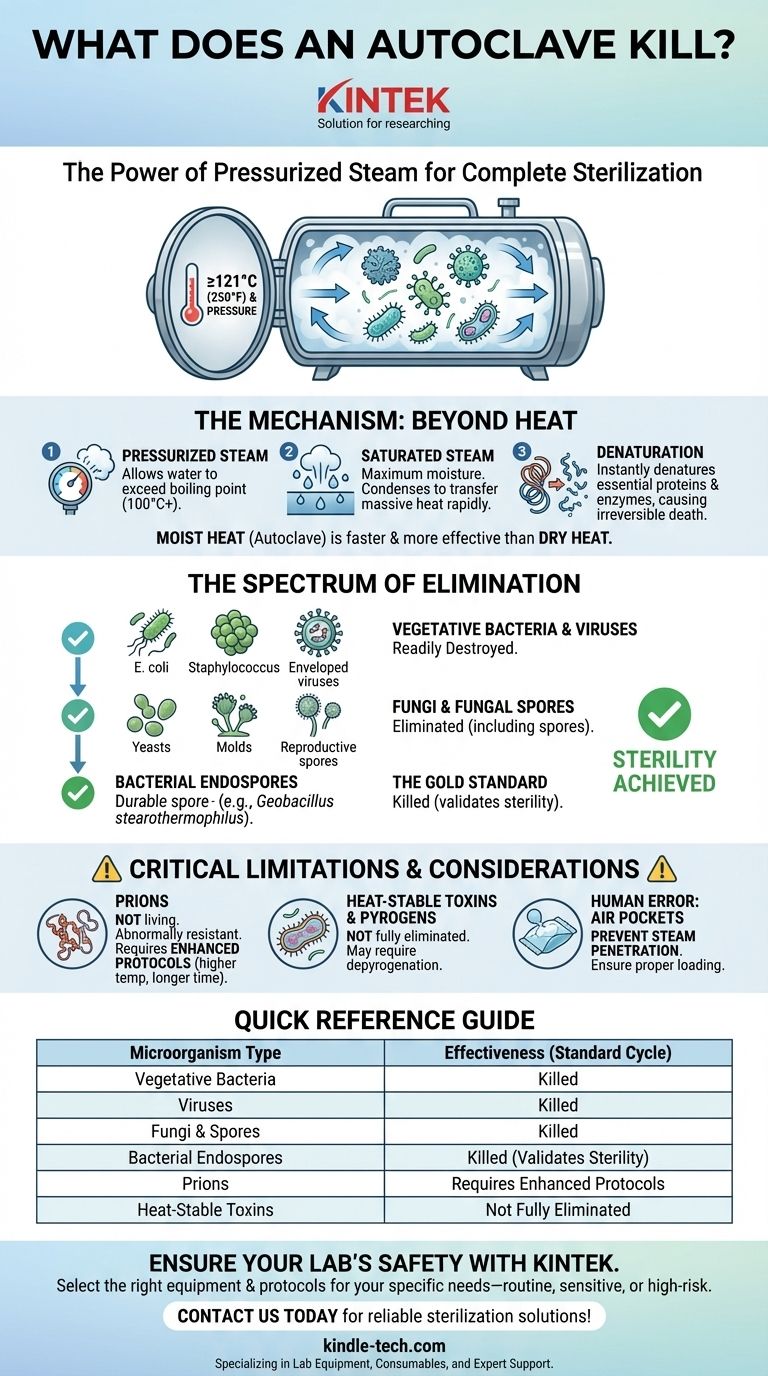

In short, an autoclave is designed to kill virtually all forms of microbial life. It is a sterilizer, not just a sanitizer. By using high-pressure saturated steam at temperatures typically above 121°C (250°F), an autoclave effectively destroys bacteria, viruses, fungi, and even the most resilient bacterial spores, which are notoriously difficult to eliminate.

The core purpose of an autoclave is to achieve complete sterilization by denaturing the essential proteins and nucleic acids of all microorganisms. Its effectiveness is validated against its ability to kill the toughest bacterial endospores, but you must also understand its critical limitations with non-living contaminants like prions and toxins.

The Mechanism of Sterilization: Beyond Just Heat

To understand what an autoclave kills, you must first understand how it works. The process is far more effective than simply using a hot oven.

The Role of Pressurized Steam

Inside an autoclave, pressure is increased, which allows water to exist as steam at temperatures well above its normal boiling point of 100°C (212°F). This high temperature is the primary killing agent.

Why Saturated Steam is Key

The critical element is saturated steam—steam that contains the maximum possible amount of water vapor. This moisture is essential for sterilization.

When this hot steam makes contact with a cooler item, it condenses into liquid water, rapidly and efficiently transferring a massive amount of heat. This process instantly denatures the vital proteins and enzymes within any microorganism, causing irreversible damage and death.

Dry Heat vs. Moist Heat

Moist heat sterilization (autoclaving) is significantly faster and more effective than dry heat sterilization. The moisture helps break down microbial proteins at lower temperatures and in less time than dry heat would require.

The Spectrum of What an Autoclave Eliminates

An autoclave's effectiveness is measured by its ability to neutralize a wide range of biological agents.

All Vegetative Bacteria and Viruses

Standard vegetative bacteria, like E. coli or Staphylococcus, and all known viruses (including enveloped and non-enveloped types) are readily destroyed by the heat and steam in a standard autoclave cycle.

Fungi and Their Spores

Fungi, including yeasts and molds, are also eliminated. This includes their reproductive spores, which are generally more resistant than the vegetative form but cannot survive proper autoclaving conditions.

The Gold Standard: Bacterial Endospores

The true test of any sterilization process is its ability to kill bacterial endospores. Organisms like Geobacillus stearothermophilus and Bacillus species form these dormant, armor-like structures to survive extreme conditions.

Because endospores are the most resistant known form of life, they are used in biological indicators (spore tests) to validate that an autoclave is functioning correctly. If a cycle can kill these spores, it is considered successful in achieving sterility.

Understanding the Critical Limitations

While incredibly effective, an autoclave is not a magical solution for all contamination. Understanding its boundaries is crucial for safety and efficacy.

The Challenge of Prions

Prions are not living organisms; they are misfolded infectious proteins that cause diseases like Creutzfeldt-Jakob Disease (CJD). They are abnormally resistant to standard autoclaving.

Destroying prions requires more aggressive protocols, such as using higher temperatures (134°C) for extended cycle times (up to 60 minutes) or pre-treating instruments with chemical agents like sodium hydroxide.

Heat-Stable Toxins and Pyrogens

An autoclave kills the bacteria, but it does not necessarily destroy the toxins they may have produced. Endotoxins, components of the cell wall of gram-negative bacteria, are a common example.

While autoclaving can reduce these pyrogens (fever-inducing substances), it may not eliminate them completely. Processes requiring pyrogen-free materials, such as pharmaceutical production, often require separate depyrogenation steps like high-temperature dry heat.

Improper Loading and Air Pockets

The most common cause of autoclave failure is human error. If a chamber is overloaded or items are wrapped improperly, air pockets can form.

Steam cannot penetrate these air pockets, leaving the items within unsterilized. This is not a limitation of the principle but of its application.

How to Apply This to Your Goal

Your sterilization requirements depend entirely on your specific application.

- If your primary focus is routine lab or medical instrument sterilization: A standard, validated cycle (e.g., 121°C for 15-20 minutes) is sufficient to eliminate all bacteria, viruses, fungi, and spores.

- If you are handling instruments used in neurosurgery or materials potentially contaminated with CJD: You must use enhanced, prion-specific decontamination protocols involving higher temperatures, longer times, and often chemical pre-treatment.

- If you are preparing materials that must be pyrogen-free for pharmaceutical or research use: Autoclaving is only one step; you must incorporate specific depyrogenation methods to eliminate heat-stable bacterial toxins.

Ultimately, an autoclave is an exceptionally powerful tool, and understanding both its capabilities and its boundaries is the key to ensuring absolute sterility and safety.

Summary Table:

| Microorganism Type | Effectiveness of Standard Autoclave Cycle |

|---|---|

| Vegetative Bacteria (e.g., E. coli) | Killed |

| Viruses (enveloped & non-enveloped) | Killed |

| Fungi & Fungal Spores | Killed |

| Bacterial Endospores (e.g., Geobacillus) | Killed (validates sterility) |

| Prions (e.g., CJD agents) | Requires enhanced protocols |

| Heat-Stable Toxins (e.g., endotoxins) | Not fully eliminated |

Ensure your lab's safety and compliance with reliable sterilization solutions from KINTEK.

An autoclave is essential for destroying bacteria, viruses, fungi, and spores, but selecting the right equipment and protocols is critical for your specific needs—whether you're handling routine lab instruments, sensitive pharmaceutical materials, or high-risk prion-contaminated items.

KINTEK specializes in lab equipment and consumables, serving laboratory needs with autoclaves that deliver precise temperature control, validated cycles, and expert support. Let us help you achieve absolute sterility and meet regulatory standards.

Contact us today to discuss your sterilization requirements and find the perfect autoclave for your lab!

Visual Guide

Related Products

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

People Also Ask

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam

- Why is a laboratory high-pressure autoclave sterilizer necessary? Ensure Accuracy in Antibacterial Research

- What is the function of laboratory autoclaves in SCWR research? Predict Material Compatibility and Corrosion Kinetics

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization