In essence, autoclaving destroys bacteria through a combination of high-temperature steam and immense pressure. This process is not merely about heating; it's a systematic method that causes the vital proteins and enzymes within a bacterium to break down and clump together, a fatal process known as coagulation. This irreversible damage ensures complete sterilization, killing not just active bacteria but also their highly resistant spores.

The true power of an autoclave lies in its use of pressurized steam. By increasing the pressure, it forces water to exist as steam at temperatures far above boiling, enabling the heat to penetrate and destroy microorganisms more rapidly and effectively than dry heat ever could.

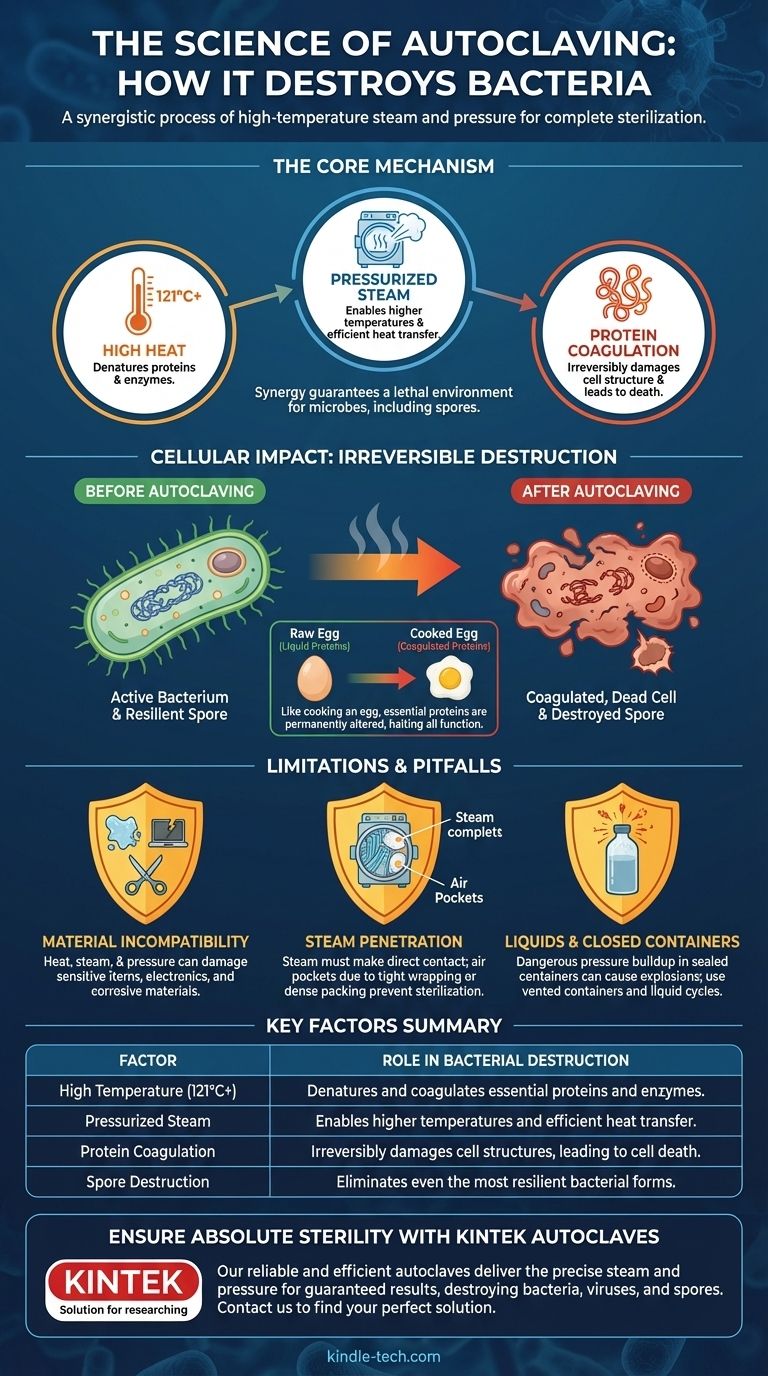

The Core Mechanism: Heat, Steam, and Pressure

To understand why autoclaving is the gold standard for sterilization, we must first appreciate the role of its three core components. It's the synergy between them that guarantees a lethal environment for microbes.

Why Simple Boiling Isn't Enough

Boiling water at standard atmospheric pressure only reaches 100°C (212°F). While this temperature can kill many types of bacteria, it is often insufficient to eliminate highly resilient bacterial endospores, which can enter a dormant state and survive extreme conditions.

The Role of Pressurized Steam

An autoclave is a sealed chamber that increases the internal pressure. According to physical laws, as pressure increases, the boiling point of water also increases. This allows an autoclave to create steam at temperatures like 121°C (250°F) or even higher, far beyond what's possible in an open environment.

How Steam Delivers Lethal Heat

Steam is an exceptionally efficient medium for heat transfer. When this superheated steam encounters the cooler surfaces of the items being sterilized (and the microbes on them), it condenses back into water. This phase change releases a massive amount of thermal energy directly onto the microorganisms, heating them far more quickly and deeply than dry air at the same temperature.

The Cellular Impact: Irreversible Destruction

The high temperature delivered by the steam triggers a catastrophic failure within the bacterial cell itself. The process is swift, comprehensive, and permanent.

The Protein Coagulation Effect

Think of cooking an egg. The clear, liquid egg white turns into an opaque, solid mass. This is coagulation—the proteins have been denatured and their structure has been irreversibly altered. The autoclave does the exact same thing to the essential structural proteins and enzymes within a bacterium.

Destroying Essential Structures and Functions

This widespread coagulation causes the bacterium's cell wall to break down, its metabolic processes to halt, and its genetic material to be destroyed. Once its core components have been "cooked," the cell can no longer function or reproduce. It is effectively and permanently dead.

Understanding the Limitations and Pitfalls

While incredibly effective, autoclaving is not a universal solution. Understanding its limitations is critical for proper use and preventing sterilization failures.

Material Incompatibility

The combination of high heat, steam, and pressure can damage or destroy many materials. Heat-sensitive plastics, delicate electronics, corrosive materials, and certain sharp instruments (which can be dulled) are not suitable for autoclaving.

The Critical Need for Steam Penetration

Sterilization only occurs where the steam makes direct contact. If instruments are wrapped too tightly or the autoclave is packed too densely, "air pockets" can form that prevent steam from penetrating. These areas will not reach the required temperature and will not be sterilized.

Liquids and Closed Containers

Attempting to autoclave a sealed container of liquid is extremely dangerous. The pressure build-up inside the container can cause it to explode. Liquids must be in vented containers, and the autoclave must be run on a slower "liquid cycle" to prevent them from boiling over.

Making the Right Choice for Your Goal

Applying this knowledge correctly ensures the integrity of your sterilization process. Your specific goal determines how you should view the autoclave's role.

- If your primary focus is sterilizing durable medical or lab equipment: Trust the autoclave as the most reliable method for destroying all forms of microbial life, including the toughest bacterial spores.

- If you are working with heat-sensitive items: Autoclaving is the wrong tool; you must use a low-temperature sterilization method like ethylene oxide (EtO) gas, hydrogen peroxide plasma, or chemical sterilization.

- If you are validating a new sterilization protocol: Always use biological indicators (vials of highly resistant spores) placed in the most challenging parts of the load to definitively prove the cycle achieves a complete kill.

Ultimately, proper autoclaving provides an absolute certainty of sterility that few other methods can match.

Summary Table:

| Key Factor | Role in Bacterial Destruction |

|---|---|

| High Temperature (121°C+) | Denatures and coagulates essential proteins and enzymes. |

| Pressurized Steam | Enables higher temperatures and efficient heat transfer. |

| Protein Coagulation | Irreversibly damages cell structures, leading to cell death. |

| Spore Destruction | Eliminates even the most resilient bacterial forms. |

Ensure absolute sterility in your laboratory with KINTEK autoclaves.

Our reliable and efficient autoclaves are designed to deliver the precise combination of high-temperature steam and pressure necessary to completely destroy bacteria, viruses, and spores. Whether you are sterilizing surgical instruments, lab glassware, or media, KINTEK provides the equipment you need for guaranteed results.

Contact us today to find the perfect autoclave solution for your laboratory's specific needs and experience the KINTEK standard of performance and support. Get in touch via our contact form.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What are the handling procedures of autoclave? A Step-by-Step Guide to Safe Sterilization

- What are the advantages of using a large-capacity autoclave for the secondary curing of calcium silicate specimens?

- Why is an autoclave required for treating biomass hydrolysate? Ensure Sterile Fermentation for High Yields

- What conditions does an autoclave simulate for 316L SCC testing? Replicating PWR Primary Circuit Environments

- What is the difference between an autoclave and a retort? Unlock the Key to Sterilization vs. Food Safety

- What is the proper pressure and temperature for sterilizing instruments? Achieve True Sterility with the Right Parameters

- What is the application of retort machine in food industry? Ensuring Shelf-Stable Food Safety and Longevity

- What is the function of an Autoclave in paper pretreatment? Boost Saccharification Yield with Precision Heating