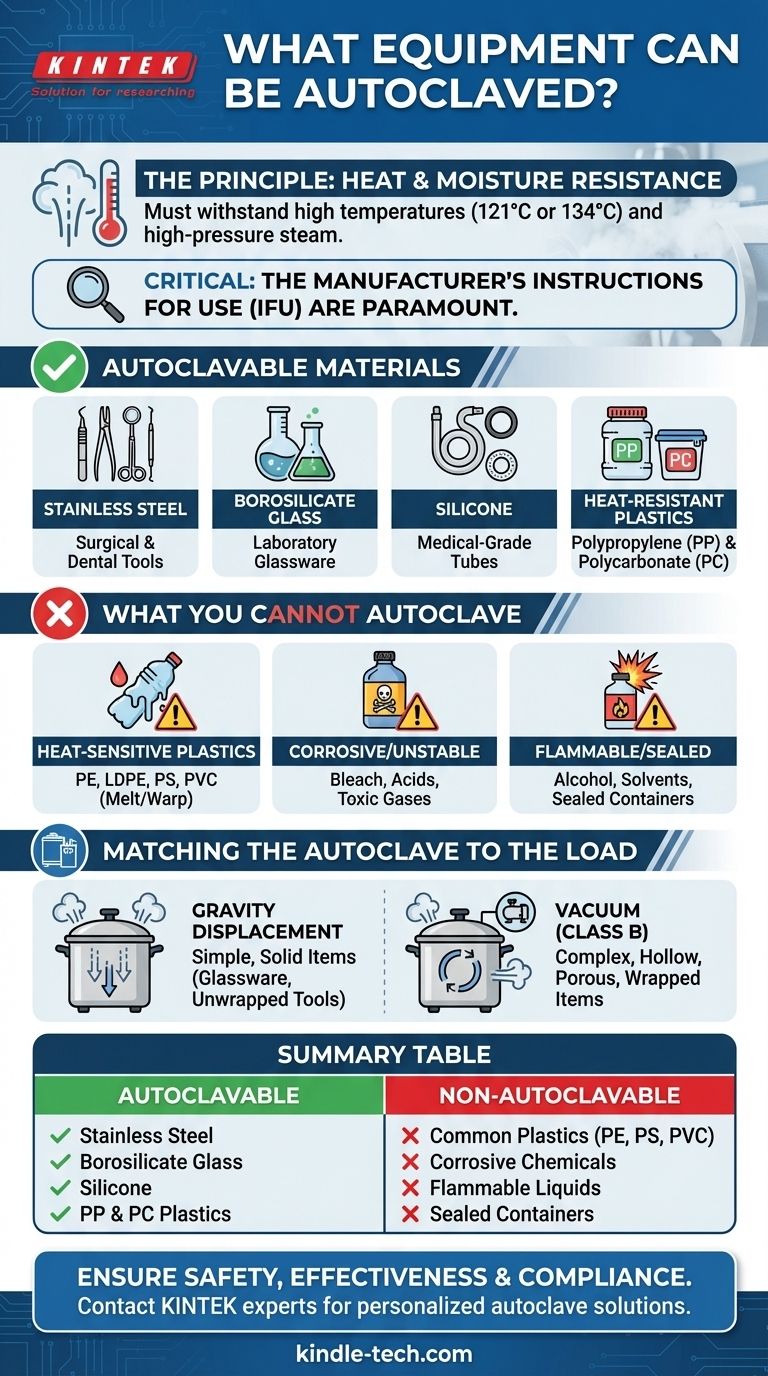

In principle, any equipment that can withstand high temperatures (typically 121°C or 134°C) and high-pressure steam can be autoclaved. This includes items made from materials like stainless steel, borosilicate glass (e.g., Pyrex), silicone, and specific types of heat-resistant plastics such as polypropylene (PP) and polycarbonate (PC). However, the ultimate authority on whether an item is autoclavable is always the manufacturer's written instructions for use (IFU).

The core issue is not creating a definitive list of items, but understanding the principle of material compatibility. Effective and safe sterilization depends on confirming that an item's material can endure high heat and moisture without melting, warping, or degrading.

The Fundamental Principle: Heat and Moisture Resistance

An autoclave works by using steam under pressure to reach temperatures high enough to kill all microorganisms. Any item placed inside must be able to survive this harsh environment.

Heat-Stable Materials

The most common autoclavable materials are chosen for their high melting points and structural integrity under heat. These include:

- Stainless Steel: The standard for surgical and dental instruments.

- Borosilicate Glass: Laboratory glassware (beakers, flasks) is often made of this to prevent cracking from thermal shock.

- Silicone: Many medical-grade tubes and seals are made from heat-resistant silicone.

- Heat-Resistant Plastics: Primarily polypropylene (PP) and polycarbonate (PC). Always check the plastic for a marking indicating its type.

Items That Must Remain Unchanged by Moisture

The process uses saturated steam, meaning everything inside will become wet. The equipment must not be susceptible to corrosion, water damage, or any degradation from moisture. This is why most electronics are unsuitable.

The Manufacturer's Instructions are Paramount

Before autoclaving any piece of equipment, especially complex or expensive devices, you must consult the manufacturer's IFU. This document will state explicitly whether the item is autoclavable and specify the required cycle parameters (temperature, pressure, and time). Failure to do so can result in damaged equipment and ineffective sterilization.

What You Cannot Autoclave

Understanding what to exclude is just as critical for safety and preventing damage. Placing the wrong material in an autoclave can destroy the item, damage the autoclave, and release hazardous fumes.

Heat-Sensitive Plastics

Most common plastics will melt. Never autoclave items made from:

- Polyethylene (PE) or Low-Density Polyethylene (LDPE)

- Polystyrene (PS)

- Polyvinyl Chloride (PVC)

Corrosive or Unstable Materials

Do not autoclave solutions of bleach, acids, or other corrosive chemicals. Non-stainless steel will rust, and certain chemicals can release toxic gases under heat and pressure.

Flammable Liquids or Sealed Containers

Never autoclave flammable substances like alcohol or solvents. Additionally, do not autoclave a completely sealed container (e.g., a bottle with a tightly screwed cap). The pressure buildup inside the container can cause it to explode. Lids must be loosened.

Understanding the Trade-offs: Matching the Autoclave to the Load

The type of autoclave you use directly impacts what you can sterilize effectively. The primary distinction is how air is removed from the chamber, which is critical for steam to penetrate the load.

Simple, Solid Items (Gravity Displacement Autoclaves)

A gravity displacement autoclave works by pumping steam into the chamber, which is heavier than air and displaces it downwards. This method is effective for non-porous items like lab glassware, media solutions, and unwrapped metal instruments.

Complex, Hollow, or Wrapped Items (Vacuum Autoclaves)

When sterilizing items with lumens (hollow tubes), porous materials (like surgical gowns), or wrapped instrument cassettes, air can become trapped inside. Trapped air pockets prevent steam from reaching all surfaces, leading to sterilization failure.

A vacuum-induced autoclave, such as a Class B model, solves this. It uses a vacuum pump to actively remove all air from the chamber before introducing steam. This ensures full steam penetration for even the most complex loads. This is why Class B autoclaves are the standard for medical and dental practices.

Making the Right Choice for Your Goal

Your sterilization needs will determine the equipment you can process and the autoclave you require.

- If your primary focus is general lab sterilization: You can reliably autoclave borosilicate glassware, stainless steel tools, and items made from polypropylene (PP), often using a simple gravity displacement unit.

- If your primary focus is medical or dental instrument processing: You must use a Class B vacuum autoclave to handle hollow instruments, wrapped cassettes, and porous loads to guarantee complete sterilization.

- If your primary focus is safety and compliance: Always default to the manufacturer's instructions for use (IFU) for both the instrument and the autoclave itself before proceeding.

Ultimately, successful autoclaving is a matter of matching the right material and item type to the correct sterilization cycle and machine.

Summary Table:

| Autoclavable Materials | Non-Autoclavable Materials |

|---|---|

| Stainless Steel Instruments | Common Plastics (PE, LDPE, PS, PVC) |

| Borosilicate Glassware | Corrosive Chemicals (Bleach, Acids) |

| Silicone Tubing & Seals | Flammable Liquids |

| Polypropylene (PP) & Polycarbonate (PC) | Sealed Containers |

Ensure your sterilization process is safe, effective, and compliant. The right autoclave is critical for your specific needs, whether you're processing simple lab glassware or complex medical instruments. KINTEK specializes in lab equipment and consumables, serving laboratory needs with the right autoclave solutions for your application. Contact our experts today for a personalized consultation and ensure your equipment and protocols are perfectly matched.

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What is autoclave used for sterilization of? Essential Guide for Lab & Medical Safety

- What are the disadvantages of autoclave in microbiology? Key Limitations for Lab Safety

- What are the guidelines when sterilizing items with a steam autoclave? Master the 3 Pillars for Guaranteed Sterility

- What are the risks of using an autoclave? Avoid Severe Burns and Sterilization Failures

- Why use a Teflon-lined stainless steel autoclave for TiO2 nanobelts? Achieve Extreme Chemical & Pressure Resistance

- What is the function of a high-pressure hydrothermal autoclave in the urea hydrolysis method? Expert Synthesis Guide

- What are the three components of autoclaving? Temperature, Pressure, and Time

- What are the two types of autoclave used in the laboratory? Gravity vs. Pre-Vacuum Explained