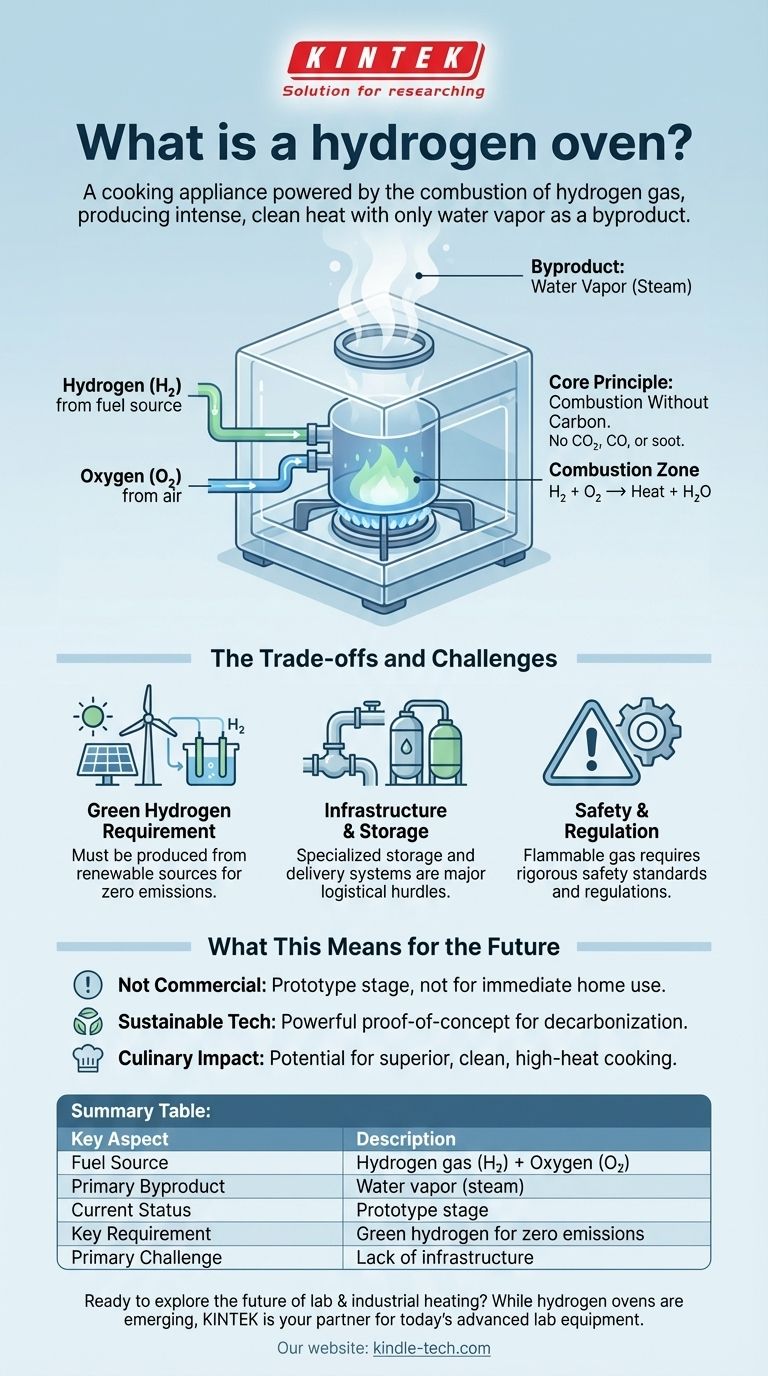

In simple terms, a hydrogen oven is a cooking appliance that uses the combustion of hydrogen gas as its heat source. Unlike conventional ovens that rely on electricity, natural gas, or wood, a hydrogen oven burns hydrogen with oxygen to generate intense, clean heat, with the primary byproduct being water vapor (steam).

A hydrogen oven replaces traditional fuels with clean-burning hydrogen. The core innovation is not the oven's structure but the fuel source, which creates high temperatures for cooking while producing only water as an emission.

The Core Principle: Combustion Without Carbon

The concept behind a hydrogen oven is rooted in basic chemistry. It leverages the unique properties of hydrogen as a fuel to create heat without the carbon emissions associated with fossil fuels.

How It Generates Heat

A hydrogen oven is equipped with a specialized burner system designed to safely mix hydrogen gas (H₂) with oxygen (O₂) from the surrounding air. When ignited, this mixture combusts in a chemical reaction that releases a significant amount of energy as heat. This process can achieve very high temperatures, making it suitable for applications like baking pizza, which benefits from intense, radiant heat.

The Key Byproduct: Water Vapor

The most significant feature of a hydrogen-fueled process is its clean emission profile. Because hydrogen fuel contains no carbon atoms, its combustion produces no carbon dioxide (CO₂), carbon monoxide (CO), or soot. The only chemical byproduct is water (H₂O), which is released as steam.

The Physical Design

From the outside, a hydrogen oven can look identical to a traditional one. Prototypes, such as the one developed by Toyota, resemble a conventional stone pizza oven with a dome, chimney, and an opening for food. The true innovation is internal, focused on the fuel delivery and burner systems that manage the hydrogen combustion.

Understanding the Trade-offs and Challenges

While the concept is promising, the widespread adoption of hydrogen ovens faces significant practical hurdles. The technology is currently more of a proof-of-concept than a market-ready product.

The "Green" Hydrogen Requirement

The environmental benefit of a hydrogen oven is entirely dependent on the source of the hydrogen. Hydrogen produced from natural gas ("grey hydrogen") has a significant carbon footprint. To be a truly zero-emission solution, the oven must run on "green hydrogen," which is produced by splitting water using electricity from renewable sources like solar or wind.

Infrastructure and Storage

Hydrogen is a less dense gas than natural gas and requires specialized infrastructure for safe storage and transportation. Implementing hydrogen for residential or commercial cooking would necessitate new pipelines or a system for delivering high-pressure storage tanks, presenting a major logistical challenge.

Safety and Regulation

Like natural gas, hydrogen is flammable and must be handled with care. While safe systems for hydrogen are well-understood in industrial settings, developing consumer-grade appliances requires rigorous safety standards, public trust, and clear regulations that are not yet in place for household use.

What This Means for the Future of Cooking

Understanding the hydrogen oven is less about a specific appliance and more about seeing a potential direction for future energy use.

- If your primary focus is immediate home application: Hydrogen ovens are not yet commercially available and remain in the prototype stage. They are not a practical option for your kitchen today.

- If your primary focus is sustainable technology: This is a powerful proof-of-concept for decarbonizing activities beyond transportation. It demonstrates how hydrogen could one day replace fossil fuels in commercial kitchens, industrial processes, and even homes.

- If your primary focus is the culinary impact: The clean, high-temperature heat from hydrogen combustion could offer superior cooking performance, similar to the best wood-fired ovens but without any smoke or soot.

Ultimately, the hydrogen oven serves as a tangible glimpse into a future where essential daily activities could be powered by clean energy.

Summary Table:

| Key Aspect | Description |

|---|---|

| Fuel Source | Hydrogen gas (H₂) combusted with oxygen (O₂). |

| Primary Byproduct | Water vapor (steam) – no CO₂ or soot. |

| Current Status | Prototype stage; not yet commercially available. |

| Key Requirement | Must use "green hydrogen" for true zero emissions. |

| Primary Challenge | Lack of infrastructure for storage and delivery. |

Ready to explore the future of lab and industrial heating?

While hydrogen ovens are still emerging, KINTEK is your trusted partner for today's advanced and reliable laboratory equipment. We specialize in furnaces and ovens that deliver precise temperature control and clean performance for your specific application needs.

Contact our experts today to discuss how our solutions can enhance your lab's efficiency, safety, and sustainability.

Visual Guide

Related Products

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- 1200℃ Muffle Furnace Oven for Laboratory

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

People Also Ask

- What is a reducing type of atmosphere? Control Oxidation & Achieve Specific Chemical Reactions

- Why is a high-temperature furnace with argon gas protection preferred for sintering sulfide particles?

- How are the mixture components calculated for a nitrogen-methanol atmosphere? Essential Ratios for Precise Control

- What is the role of a high-temperature atmosphere furnace in purifying chloride molten salts? Master Dehydration.

- What is a high temperature inert atmosphere furnace? Control Your Heat Treatment Process

- Why does furnace use nitrogen? Prevent Oxidation for Flawless High-Temperature Processing

- How does a High-Temperature Atmosphere Furnace ensure the quality of the nitrided layer? Ensure Precision & Durability

- What does inerting a space mean? A Guide to Eliminating Fire and Explosion Risks