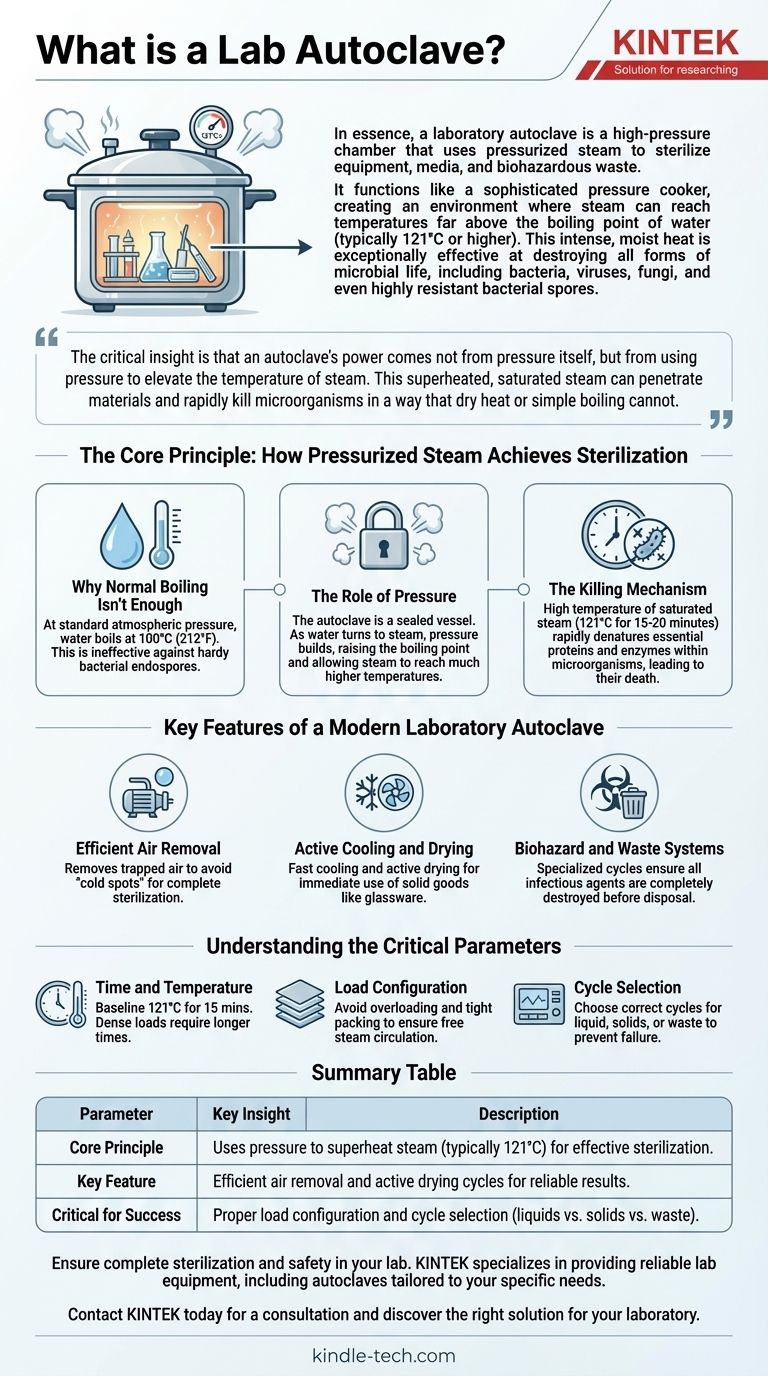

In essence, a laboratory autoclave is a high-pressure chamber that uses pressurized steam to sterilize equipment, media, and biohazardous waste. It functions like a sophisticated pressure cooker, creating an environment where steam can reach temperatures far above the boiling point of water (typically 121°C or higher). This intense, moist heat is exceptionally effective at destroying all forms of microbial life, including bacteria, viruses, fungi, and even highly resistant bacterial spores.

The critical insight is that an autoclave's power comes not from pressure itself, but from using pressure to elevate the temperature of steam. This superheated, saturated steam can penetrate materials and rapidly kill microorganisms in a way that dry heat or simple boiling cannot.

The Core Principle: How Pressurized Steam Achieves Sterilization

To understand why autoclaves are the gold standard for sterilization, we must first understand the limitations of boiling water and the physics of steam.

Why Normal Boiling Isn't Enough

At standard atmospheric pressure, water boils at 100°C (212°F). While this temperature is sufficient to kill many types of bacteria, it is ineffective against hardy bacterial endospores, which can survive boiling for extended periods.

The Role of Pressure

The autoclave chamber is a sealed vessel. As water inside is heated, it turns to steam, and because this steam cannot escape, the pressure inside the chamber builds. This increased pressure directly raises the boiling point of water, allowing the steam to reach much higher temperatures.

The Killing Mechanism

The actual sterilization is performed by the high temperature of the saturated steam, typically 121°C (250°F) held for at least 15-20 minutes. This moist heat is highly efficient at transferring energy, which rapidly denatures the essential proteins and enzymes within microorganisms, leading to their death.

Key Features of a Modern Laboratory Autoclave

While the core principle is simple, modern autoclaves incorporate features designed for efficiency, safety, and reliability.

Efficient Air Removal

One of the most critical steps is removing all the air from the chamber before the sterilization cycle begins. Trapped air creates "cold spots" that steam cannot reach, leading to incomplete sterilization. Many autoclaves use vacuum systems for this purpose.

Active Cooling and Drying

After sterilization, safely handling the load is paramount. Modern units feature fast cooling systems to reduce the time needed before the chamber can be opened. For solid goods like glassware or instruments, an active drying phase uses a vacuum to remove all residual moisture, leaving items ready for immediate use.

Biohazard and Waste Systems

Autoclaves are essential for decontaminating hazardous biological waste. Specialized cycles and containment features ensure that all infectious agents are completely destroyed before the waste is discarded, protecting both lab personnel and the environment.

Understanding the Critical Parameters

Effective autoclaving is not a "set it and forget it" process. Failure to control key parameters is the most common cause of sterilization failure.

Time and Temperature

The standard 121°C for 15 minutes is a baseline. Dense or large-volume loads require longer cycle times to ensure the steam fully penetrates to the core of the material and holds it at the target temperature for the required duration.

Load Configuration

How you load the autoclave is crucial. Overloading the chamber or packing items too tightly prevents steam from circulating freely. This is a primary cause of failed cycles, as it effectively creates the same "cold spots" as trapped air.

Cycle Selection

Modern autoclaves have pre-programmed cycles for different materials. A "liquid" cycle uses a slow, controlled pressure release to prevent media from boiling over, while a "solids" or "glassware" cycle includes a final drying phase. Using the wrong cycle can ruin the load or result in incomplete sterilization.

A Practical Workflow for Safe and Effective Use

Applying these principles correctly ensures that every cycle is successful and safe.

- If your primary focus is sterilizing liquid media: Use a dedicated liquid cycle with a slow exhaust and ensure containers are no more than two-thirds full to prevent boiling over during depressurization.

- If your primary focus is sterilizing instruments or glassware: Choose a gravity or vacuum cycle that includes a post-sterilization drying phase to ensure items are ready for use.

- If your primary focus is decontaminating biohazardous waste: Select a specific biohazard cycle with extended time and use validated autoclave bags to ensure complete steam penetration and containment.

Mastering the use of an autoclave is fundamental to ensuring the safety and integrity of scientific work.

Summary Table:

| Parameter | Key Insight |

|---|---|

| Core Principle | Uses pressure to superheat steam (typically 121°C) for effective sterilization. |

| Key Feature | Efficient air removal and active drying cycles for reliable results. |

| Critical for Success | Proper load configuration and cycle selection (liquids vs. solids vs. waste). |

Ensure complete sterilization and safety in your lab.

An autoclave is a critical investment for any laboratory focused on accuracy and safety. KINTEK specializes in providing reliable lab equipment, including autoclaves tailored to your specific needs—whether for sterilizing liquid media, glassware, or decontaminating biohazardous waste.

Let our experts help you select the right autoclave to protect your work and your team. Contact KINTEK today for a consultation and discover the right solution for your laboratory.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tube Racks

People Also Ask

- What is the function of high-pressure autoclaves in LH synthesis of zeolite membranes? Key Roles & Benefits

- What is the most common hazard of using an autoclave? Prevent Severe Thermal Burns and Accidents

- Why is a Teflon-lined autoclave necessary for the hydrothermal treatment of porous TiO2 nanomaterials? Expert Insights

- What is the function of an industrial-grade 316 stainless steel autoclave? Master PWR Secondary Circuit Simulation

- What are the limitations of an autoclave? Understanding Material Compatibility and Safety Constraints

- What are the limitations of autoclave sterilization? Avoid Costly Damage to Your Lab Equipment

- What are the settings for autoclave sterilization? Ensure Reliable Sterility with Proper Parameters

- Why is an Autoclave essential for simulating nuclear reactor conditions during the corrosion testing of zirconium alloys?