In short, an evaporation machine is a high-tech system used to apply an ultra-thin, exceptionally pure coating of material onto a surface inside a vacuum chamber. It operates by heating a source material until it turns into a vapor, which then travels and condenses onto a target object, known as a substrate. The most advanced and common type is the electron beam (e-beam) evaporator, which uses a precisely focused beam of high-energy electrons to vaporize the source material with incredible control.

An evaporation machine is not simply for coating an object; it is a precision instrument for engineering materials at the nanoscale. By vaporizing elements in a vacuum, it creates films with controlled thickness and high purity, fundamentally altering a substrate's optical, electrical, or physical properties.

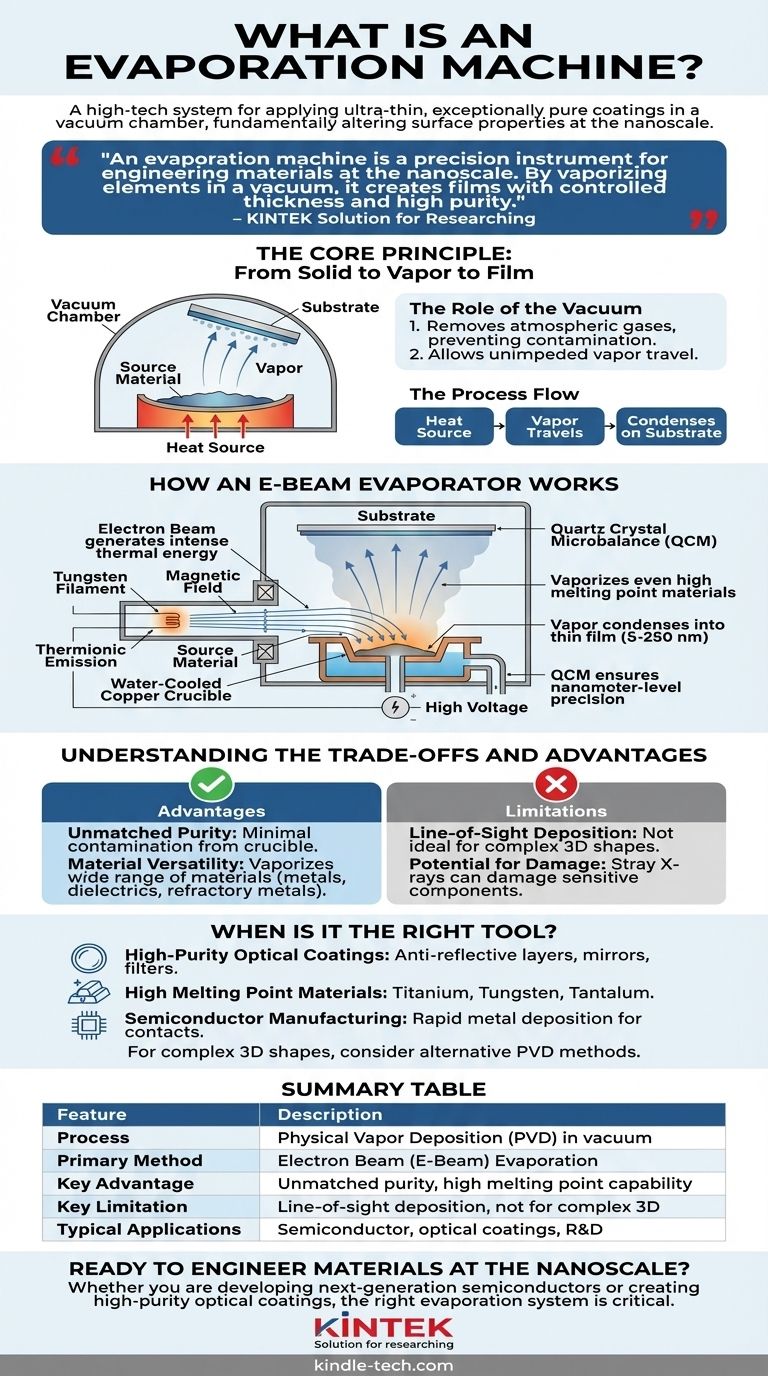

The Core Principle: From Solid to Vapor to Film

Evaporation is a type of Physical Vapor Deposition (PVD), a foundational process in materials science and semiconductor manufacturing. The entire process hinges on a simple phase transition managed under highly controlled conditions.

The Role of the Vacuum

The process must occur in a high vacuum environment. This is non-negotiable for two reasons. First, it removes atmospheric gases that could react with the vapor and contaminate the final film. Second, it allows the vaporized atoms to travel unimpeded from the source to the substrate.

The Process Flow

All evaporation systems follow the same fundamental steps: a source material is heated until it evaporates, the resulting vapor travels through the vacuum, and it finally condenses as a solid thin film on the cooler substrate.

How an E-Beam Evaporator Works

While simpler thermal evaporators exist, the e-beam evaporator is the industry standard for high-performance applications. It offers unparalleled control and purity by using a focused stream of electrons as the heat source.

Generating the Electron Beam

A tungsten filament is heated to extreme temperatures, causing it to release a cloud of electrons through a process called thermionic emission. A high voltage (typically 5-10 kV) is then applied to accelerate these electrons into a high-energy beam.

Targeting the Source Material

This beam is magnetically steered and focused onto the desired source material, which rests in a water-cooled copper crucible. The active cooling is critical; it ensures that only the source material is heated, preventing the crucible itself from melting or releasing impurities.

The Energy Transfer

When the high-energy electrons strike the source, their kinetic energy is instantly converted into intense thermal energy. This heat is so localized and powerful that it can melt and vaporize even materials with extremely high melting points, such as tungsten or tantalum.

Deposition and Precision Control

The resulting vapor cloud travels upward in the vacuum chamber and condenses on the substrate positioned above. This forms a thin film with a typical thickness between 5 and 250 nanometers.

To ensure precision, systems use a Quartz Crystal Microbalance (QCM). This device monitors the deposition rate in real-time, allowing for precise control over the final film thickness down to the single-nanometer level.

Understanding the Trade-offs and Advantages

No technology is perfect. Understanding the strengths and weaknesses of e-beam evaporation is key to using it effectively.

Key Advantage: Unmatched Purity

Because the electron beam only heats the source material, contamination from the crucible is virtually eliminated. This results in films of exceptionally high purity, which is critical for optical and electronic applications.

Key Advantage: Material Versatility

The intense, focused heat can vaporize a vast range of materials, including metals, dielectrics, and even refractory metals with very high melting points that are impossible to evaporate with simpler thermal methods.

Limitation: Line-of-Sight Deposition

The vapor travels in a straight line from the source to the substrate. This means e-beam evaporation is excellent for coating flat surfaces but is not effective for uniformly coating complex, three-dimensional shapes with shadowed areas or undercuts.

Limitation: Potential for Damage

The high-energy electrons can generate stray X-rays upon impact with the source material. In some cases, this radiation can damage sensitive electronic components or polymer substrates.

When Is an Evaporation Machine the Right Tool?

Choosing a deposition method depends entirely on your end goal. Evaporation excels where purity and performance are paramount.

- If your primary focus is creating high-purity optical coatings: E-beam evaporation is the ideal choice for producing precise anti-reflective layers, mirrors, and filters.

- If your primary focus is depositing materials with high melting points: The intense, localized heating of an e-beam is one of the few effective methods for materials like titanium, tungsten, or tantalum.

- If your primary focus is rapid metal deposition in semiconductor manufacturing: E-beam evaporation offers excellent film quality and high deposition rates for creating electrical contacts and interconnects.

- If your primary focus is coating a complex 3D object uniformly: You should consider an alternative PVD method like sputtering, which does not have the same line-of-sight limitation.

Ultimately, an evaporation system is a fundamental tool for engineering new materials from the atoms up, enabling innovation across modern science and technology.

Summary Table:

| Feature | Description |

|---|---|

| Process | Physical Vapor Deposition (PVD) in a vacuum chamber |

| Primary Method | Electron Beam (E-Beam) Evaporation |

| Key Advantage | Unmatched film purity and high melting point material capability |

| Key Limitation | Line-of-sight deposition, not ideal for complex 3D shapes |

| Typical Applications | Semiconductor manufacturing, optical coatings, research & development |

Ready to engineer materials at the nanoscale?

Whether you are developing next-generation semiconductors, creating high-purity optical coatings, or advancing materials research, the right evaporation system is critical to your success.

KINTEK specializes in premium lab equipment, including advanced evaporation machines and consumables, tailored to meet the precise needs of your laboratory. Our experts can help you select the ideal system to achieve the high-purity, controlled thin films your work demands.

Contact our team today to discuss your project requirements and discover how KINTEK can enhance your lab's capabilities.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth