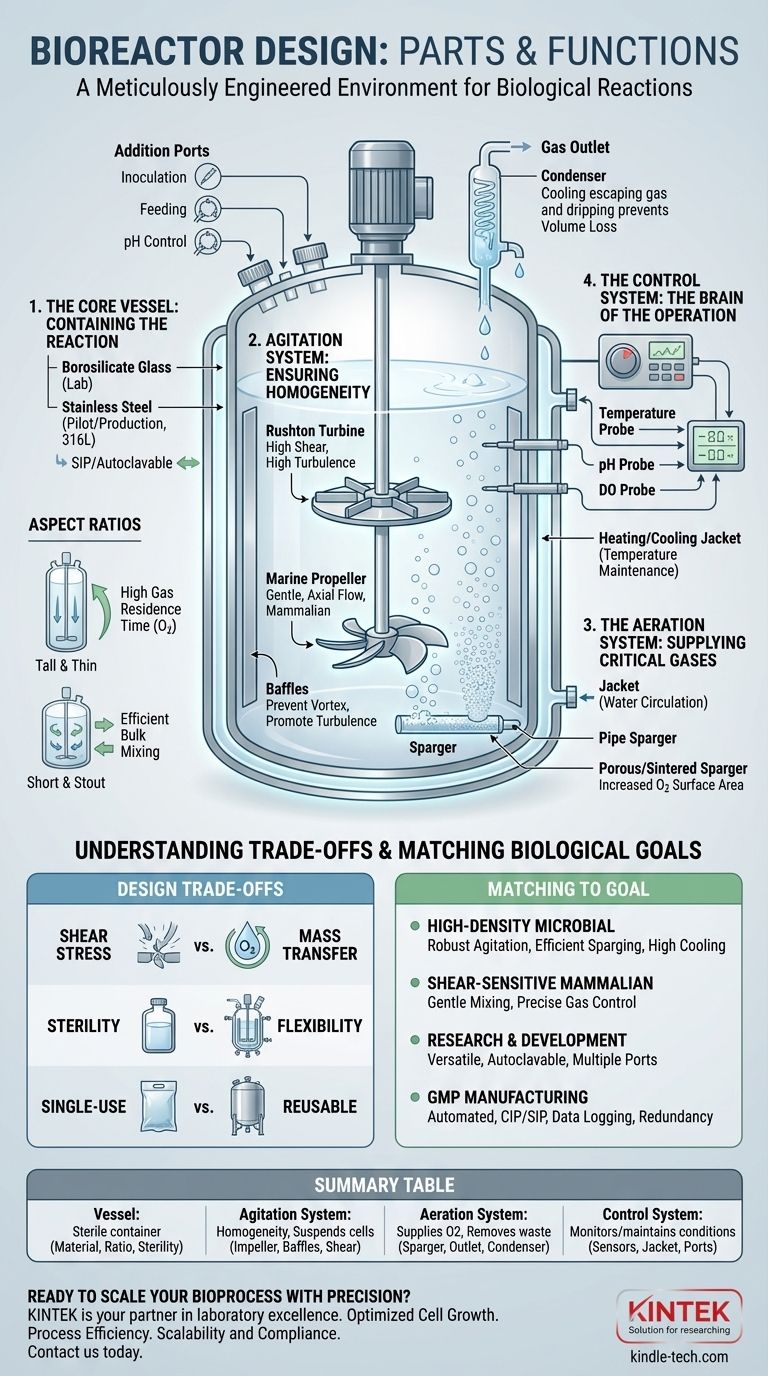

At its core, a bioreactor is a meticulously engineered environment. It is a vessel designed to carry out a biological reaction under tightly controlled conditions. The primary parts responsible for this are the vessel itself, an agitation system (impeller and baffles) for mixing, an aeration system (sparger) to supply gas, and a control system (sensors, probes, and jackets) to monitor and maintain the ideal state for cellular growth.

A bioreactor is more than just a container; it is an integrated system where each component works in concert. Understanding its design is not about memorizing a parts list, but about grasping how these parts synergize to solve the fundamental challenges of mass transfer, heat transfer, and sterility for a specific biological process.

The Core Vessel: Containing the Reaction

The vessel is the foundation of the bioreactor, providing a sterile boundary between the internal culture and the outside world. Its design directly impacts the entire process.

Materials and Sterility

The vessel is typically made from borosilicate glass for smaller, laboratory-scale units or stainless steel (like 316L) for pilot and production scales. The chosen material must be non-toxic to the cells, corrosion-resistant, and capable of withstanding repeated sterilization cycles, either through autoclaving (for glass vessels) or Steam-in-Place (SIP) for steel tanks.

Aspect Ratio and Geometry

The aspect ratio (the ratio of the tank's height to its diameter) is a critical design parameter. A "tall and thin" vessel can improve gas residence time, which is beneficial for oxygen transfer, while a "short and stout" vessel may offer more efficient bulk mixing with lower power input.

The Agitation System: Ensuring Homogeneity

A static liquid is an unproductive one. The agitation system's job is to ensure the culture is uniform in temperature, pH, and nutrient concentration, and that cells remain suspended and gas bubbles are well-dispersed.

The Impeller: The Engine of Mixing

The impeller is the rotating element, driven by a motor, that imparts energy into the liquid. Different impeller types are chosen based on the process needs. A Rushton turbine creates high shear, excellent for dispersing gas bubbles in robust microbial cultures. In contrast, a marine-style propeller provides gentle, axial flow ideal for fragile mammalian cells that are sensitive to shear stress.

Baffles: Preventing Vortex Formation

Without baffles, the impeller would simply spin the liquid in a circle, creating a central vortex that leads to poor mixing and inefficient gas dispersion. Baffles are vertical strips of metal attached to the vessel's inner wall that disrupt this circular flow, promoting turbulence and ensuring the entire volume is mixed effectively.

The Aeration System: Supplying Critical Gases

Nearly all useful cell cultures are aerobic, meaning they require a constant supply of oxygen. The aeration system delivers this and removes waste gases like carbon dioxide.

The Sparger: Introducing Gas Bubbles

The sparger is the device that introduces gas (typically air or pure oxygen) into the vessel. It is usually located below the impeller. A simple pipe sparger releases large bubbles, while a more advanced porous or sintered sparger creates a cloud of very fine bubbles, dramatically increasing the surface area for oxygen to dissolve into the liquid.

The Gas Outlet and Condenser

As gas is bubbled through the culture, it strips water vapor and exits through an outlet at the top of the vessel. A condenser in the exhaust line cools the exiting gas, causing water to condense and drip back into the vessel, preventing the culture volume from decreasing over time.

The Control System: The Brain of the Operation

This is the network of sensors and actuators that monitors the culture's health and automatically adjusts conditions to keep them at their optimal setpoints.

Sensors and Probes

Probes are inserted into the culture through sterile ports to provide real-time data. The most critical are the temperature probe, pH probe, and Dissolved Oxygen (DO) probe. This data feeds back to a controller that makes decisions.

Heating and Cooling Jackets

To maintain a constant temperature, the vessel is typically surrounded by a jacket. The controller pumps hot or cold water through this jacket as needed. For highly exothermic reactions (which generate a lot of heat), internal cooling coils may also be required.

Addition Ports and Pumps

Sterile ports allow for the introduction of materials after the process has started. These are used for inoculation (adding the initial cells), feeding (adding nutrients over time), and pH control (adding acid or base via automated pumps).

Understanding the Trade-offs in Bioreactor Design

Choosing the right components is a balancing act. There is no single "best" design, only the best design for a specific application.

Shear Stress vs. Mass Transfer

Aggressive agitation with a Rushton turbine is excellent for transferring oxygen into the broth for a high-density bacterial culture. However, the high shear forces created would shred delicate mammalian or plant cells. This forces a trade-off between maximizing oxygen supply and ensuring cell viability.

Sterility vs. Flexibility

Every port, probe, and connection point is a potential contamination risk. A simple, sealed vessel is easier to keep sterile. However, a complex research bioreactor with numerous ports offers far more flexibility for sampling, feeding, and advanced monitoring.

Single-Use vs. Reusable Systems

Traditional stainless steel bioreactors are robust and long-lasting but require extensive cleaning, sterilization, and validation between batches (CIP/SIP), which is time-consuming and expensive. Single-use bioreactors, made of pre-sterilized plastic bags, eliminate this requirement, offering faster turnaround. However, they generate plastic waste and have limitations in terms of heat transfer and material leachables.

Matching Design to Your Biological Goal

The ideal bioreactor configuration depends entirely on the cells you are growing and your ultimate objective.

- If your primary focus is high-density microbial fermentation: You need a robust stainless steel system with powerful agitation (Rushton impellers), efficient sparging, and aggressive cooling capacity to handle high metabolic heat loads.

- If your primary focus is shear-sensitive mammalian cell culture: Prioritize a system with gentle mixing (marine or pitched-blade impellers, low RPM), precise gas control for CO2 and O2, and highly accurate pH monitoring.

- If your primary focus is research and development: A versatile, autoclavable glass vessel with multiple ports and interchangeable components offers the most flexibility for experimentation and process optimization.

- If your primary focus is GMP manufacturing: A fully automated stainless steel or validated single-use system with robust CIP/SIP capabilities, redundant sensors, and comprehensive data logging is non-negotiable for regulatory compliance.

Understanding how these components synergize transforms a simple vessel into a powerful and precise tool for biological innovation.

Summary Table:

| Component | Primary Function | Key Considerations |

|---|---|---|

| Vessel | Provides a sterile container for the reaction. | Material (glass/steel), aspect ratio, sterility (SIP/CIP). |

| Agitation System | Ensures homogeneity and suspends cells. | Impeller type (Rushton/marine), baffles, shear stress. |

| Aeration System | Supplies oxygen and removes waste gases. | Sparger type (pipe/porous), gas outlet, condenser. |

| Control System | Monitors and maintains optimal culture conditions. | Sensors (pH, DO, temp), heating/cooling jacket, addition ports. |

Ready to Scale Your Bioprocess with Precision?

Understanding bioreactor design is the first step. Implementing the right equipment is what drives success. Whether you are scaling up a microbial fermentation or developing a sensitive mammalian cell line, the correct bioreactor configuration is critical.

KINTEK is your partner in laboratory excellence. We specialize in providing high-quality lab equipment and consumables tailored to your specific research and production needs.

Let us help you achieve:

- Optimized Cell Growth: With equipment matched to your biological system's requirements.

- Process Efficiency: Through reliable and precise control systems.

- Scalability and Compliance: From R&D to GMP manufacturing.

Contact us today to discuss how our solutions can enhance your bioreactor processes and support your innovation goals.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Performance Laboratory Freeze Dryer

People Also Ask

- What is the contribution of a hydrothermal reactor to graded pore construction? Precision Templates for TAS

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation

- What roles do autoclaves play in MFI zeolite synthesis? Master Hydrothermal Crystalline Growth

- Why are high-pressure autoclaves essential for preparing bio-based polyamide curing agents from dimeric acid?

- How does a high-pressure reactor demonstrate its value in accelerated aging? Predict Catalyst Durability Fast