At its core, ferronickel is an alloy of iron and nickel primarily used as a key raw material in the manufacturing of stainless steel. It serves as an efficient and cost-effective method for introducing nickel into a steel melt, which is essential for producing the most common and versatile grades of stainless steel.

Ferronickel is not a finished product for consumers but a crucial industrial intermediate. Its primary function is to deliver nickel to steelmakers more economically than using pure nickel, enabling the mass production of corrosion-resistant and high-strength steels that define our modern world.

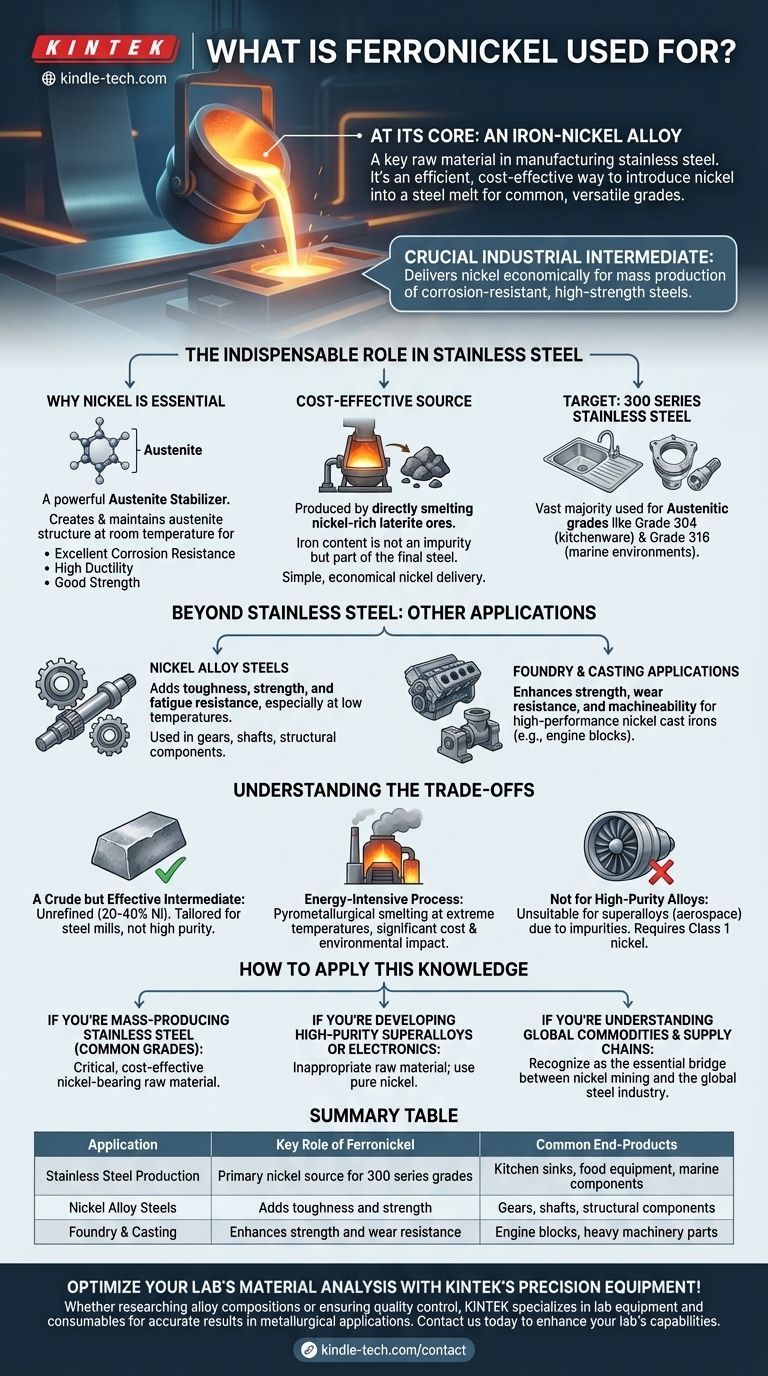

The Indispensable Role in Stainless Steel

Ferronickel's value is inextricably linked to the properties nickel imparts to steel. Without this simple alloy, the stainless steel we rely on would be far more expensive and less accessible.

Why Nickel is Essential for Steel

Nickel is a powerful austenite stabilizer. When added to steel, it helps form and maintain a specific crystal structure (austenite) at room temperature.

This austenitic structure is the source of the most desirable properties in stainless steel: excellent corrosion resistance, high ductility (the ability to be formed without breaking), and good strength.

Ferronickel as a Cost-Effective Nickel Source

Producing pure, or "Class 1," nickel is a complex and expensive refining process. Ferronickel, by contrast, is produced by directly smelting nickel-rich laterite ores.

This process is far simpler because it doesn't require the removal of the iron naturally present in the ore. For a steelmaker, this iron content is not an impurity; it simply becomes part of the final steel product, making ferronickel an ideal and economical delivery mechanism for nickel.

The Target Application: 300 Series Stainless Steel

The vast majority of ferronickel is consumed in the production of austenitic stainless steels, particularly the 300 series.

This family of steels, including the ubiquitous Grade 304 (used in kitchen sinks and food equipment) and Grade 316 (used in marine and chemical environments), relies on the nickel supplied by ferronickel for its signature performance.

Beyond Stainless Steel: Other Applications

While stainless steel accounts for the lion's share of its use, ferronickel also finds its way into other important metallurgical applications.

Nickel Alloy Steels

Certain low-alloy and alloy steels require nickel to improve their toughness, strength, and fatigue resistance, especially at low temperatures. Ferronickel is used as a source of nickel for these grades, which are often used in demanding engineering applications like gears, shafts, and structural components.

Foundry and Casting Applications

In the production of cast iron, adding nickel can significantly enhance the material's strength, wear resistance, and machineability. Ferronickel is sometimes used in foundries to produce high-performance nickel cast irons for parts like engine blocks and heavy machinery components.

Understanding the Trade-offs

To fully grasp the role of ferronickel, it's crucial to understand its limitations and the context of its production. It is a functional raw material, not a high-performance alloy in its own right.

A Crude but Effective Intermediate

Ferronickel is an unrefined product. Its composition, typically ranging from 20% to 40% nickel, is tailored for steel mills, not for high-purity applications. It is valued for what it contains, not for its own material properties.

The Energy-Intensive Process

The production of ferronickel from laterite ores is a pyrometallurgical process, meaning it involves smelting at extremely high temperatures. This is a very energy-intensive operation with significant cost and environmental considerations.

Not Suitable for High-Purity Alloys

For applications requiring extremely high purity and precise compositions, such as superalloys used in jet engines or aerospace components, ferronickel is unsuitable. These advanced materials demand the use of pure Class 1 nickel to avoid introducing unwanted impurities.

How to Apply This Knowledge

Your perspective on ferronickel depends entirely on your industrial goal. It is a tool for a specific job, and understanding its purpose is key.

- If your primary focus is mass-producing common grades of stainless steel: Ferronickel is the most critical and cost-effective nickel-bearing raw material you will use.

- If your primary focus is developing high-purity superalloys or electronics: Ferronickel is an inappropriate raw material; you must use highly refined, pure nickel cathodes or briquettes.

- If your primary focus is understanding global commodities and supply chains: Recognize ferronickel as the essential bridge connecting nickel mining operations with the global steel industry.

Ultimately, ferronickel is a foundational, unseen material that enables the strength and durability of the world around us.

Summary Table:

| Application | Key Role of Ferronickel | Common End-Products |

|---|---|---|

| Stainless Steel Production | Primary nickel source for 300 series grades | Kitchen sinks, food equipment, marine components |

| Nickel Alloy Steels | Adds toughness and strength | Gears, shafts, structural components |

| Foundry & Casting | Enhances strength and wear resistance | Engine blocks, heavy machinery parts |

Optimize your lab's material analysis with KINTEK's precision equipment!

Whether you're researching alloy compositions or ensuring quality control in steel production, KINTEK specializes in lab equipment and consumables that deliver accurate results for metallurgical applications.

Contact us today to discuss how our solutions can enhance your laboratory's capabilities in materials testing and analysis.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- How is a high-temperature calcination furnace utilized in BZY20 Sol-gel? Achieve Pure Cubic Perovskite Phases

- What temperature is needed for pyrolysis waste? A Guide to Optimizing Your Waste-to-Value Process

- Why are high temperatures required when sintering stainless steels? Unlock Pure, High-Density Results

- What are the process advantages of using a rotary tube furnace for WS2 powder? Achieve Superior Material Crystallinity

- What is the difference between pyrolysis combustion and gasification? A Guide to Thermal Conversion Technologies