battery material

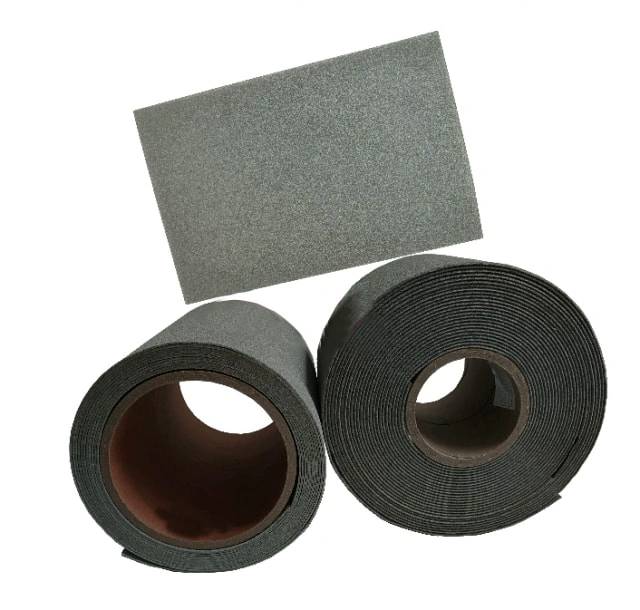

Nickel Foam for Industrial and Laboratory Applications

Item Number : BC-24

Price varies based on specs and customizations

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

Nickel foam, a member of the "porous metal" family, is a lightweight, multifunctional material with a three-dimensional network structure. Its specific gravity is only 0.2~0.3, which is very light compared with other materials. This foam has excellent sound-absorbing, heat-conducting and filtering capabilities due to its porous network. It has a high porosity of 96-98%, maintaining the favorable properties of nickel while being lighter in weight. These properties make nickel foam a functional new material with diverse applications.

- Chemical Power Sources: Enhances Ni-MH, Ni-Cd, and fuel cell batteries, doubling performance. Ideal for lithium batteries in phones, computers, scooters, etc.

- Chemical Engineering: Used as catalyst, filter medium, and separator in purifiers, reducing energy consumption and improving efficiency.

- Electrochemical Engineering: Improves energy efficiency in hydrogen production, electrocatalysis, and metallurgy.

- Thermal Engineering: Efficient heat-conducting material, doubles heat pipe efficiency.

- Functional Materials: Absorbs wave energy, provides noise reduction, vibration absorption, electromagnetic shielding, flame retardant, and heat insulation.

- Applications include exhaust gas purifiers, battery electrodes, catalyst carriers, infrared burners, and heating materials.

Detail & Parts

Technical specifications

| Aperture: | 0.1mm-10mm (5-120ppi) |

| Porosity: | 50%-98% |

| Porosity: | ≥98% |

| Bulk density: | 0.1-0.8g/cm3 |

| Surface density (g/㎡) | 280~3000 (±30~200) |

| Thickness (mm) | 0.5~10 (±0.05~1.0) |

| Length/Width Size(mm) | 70≤L/W≤500 (±0.5) |

| Size | Thickness 0.3 / 0.5 / 1.0 / 1.5 / 1.7mm*Width 200mm*Length 1m | Thickness 0.3/0.5/1.0/1.5/2.0mm*width 200mm*length 250mm | Thickness 0.5/1.0/1.5/1.7/2.5/2.0mm*width 200mm*length 300mm |

The products we show are available in different sizes and custom sizes are available on request.

Advantages

- Ultra-light quality: It has a specific surface area and a specific gravity of 0.2~0.3, which is 1/4 of water, 1/3 of wood, 1/10 of metal aluminum, and 1/30 of iron. The quality is ultra-light.

- Sound absorption: The porous structure has wide frequency sound absorption characteristics.

- Electron wave shielding: Through relatively thin thickness, it shields about 90dB of electronic waves.

- Processability: Can be cut, bent, and easily pasted.

- Fire resistance: maintain stable shape, difficult to burn at high temperature, high temperature resistance.

- Recycling: Metal scrap materials can be recycled.

- Breathable: The homogeneous three-dimensional mesh structure has the function of filtering, and the flow stability of gas and fluid is super strong.

- Sound insulation: Through additional processing, a high noise interception can be obtained, and the sound insulation effect is good.

- Sophisticated on the outside, practical on the inside: through a wide range of finishes, suitable for interior decoration.

- High temperature resistance: above 600 degrees, resistant to various acid and alkali corrosion, good permeability, uniform pore structure, fast heating and heat transfer.

Trusted by Industry Leaders

4.8 / 5

Nickel Foam's sound absorption is exceptional, making it perfect for studios and noisy environments.

4.9 / 5

The Nickel Foam from KINTEK SOLUTION is a game-changer for our battery production. It enhances performance and extends battery life significantly.

4.7 / 5

Nickel Foam's heat conduction is remarkable. It has doubled the efficiency of our heat pipes, leading to improved performance and energy savings.

4.6 / 5

The processing flexibility of Nickel Foam is fantastic. We can easily cut, bend, and paste it, making it incredibly versatile for various applications.

4.8 / 5

The recyclability of Nickel Foam is a huge plus. It aligns with our sustainability goals and reduces our environmental impact.

4.9 / 5

The breathability of Nickel Foam is impressive. Its three-dimensional mesh structure allows for efficient filtering and gas/fluid flow.

4.7 / 5

The sound insulation provided by Nickel Foam is exceptional. It effectively reduces noise pollution, creating a quieter and more comfortable environment.

4.6 / 5

The high temperature resistance of Nickel Foam is impressive. It withstands extreme heat and various acid and alkali corrosion, making it ideal for demanding applications.

4.8 / 5

Nickel Foam's sophisticated yet practical design makes it a perfect choice for interior decoration. It combines aesthetics with functionality flawlessly.

4.9 / 5

The fast heating and heat transfer of Nickel Foam are remarkable. It significantly improves the efficiency of heating systems, reducing energy consumption.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Advanced Engineering Fine Ceramics Alumina Ceramic Saggar for Fine Corundum

Alumina sagger products have the characteristics of high temperature resistance, good thermal shock stability, small expansion coefficient, anti-stripping, and good anti-powdering performance.

Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

Boron nitride ((BN) is a compound with high melting point, high hardness, high thermal conductivity and high electrical resistivity. Its crystal structure is similar to graphene and harder than diamond.

Copper Foam

Copper foam has good thermal conductivity and can be widely used for heat conduction and heat dissipation of motors/electrical appliances and electronic components.

Related Articles

Exploring the Advanced Capabilities of Spark Plasma Sintering (SPS) Furnaces

Dive into the world of Spark Plasma Sintering (SPS) furnaces, their innovative technology, and applications in material science. Learn how SPS furnaces revolutionize the sintering process with high-speed, efficiency, and precision.

Comprehensive Guide to Spark Plasma Sintering Furnaces: Applications, Features, and Benefits

Explore the advanced features and applications of Spark Plasma Sintering Furnaces (SPS) in material science. Learn how SPS technology offers rapid, efficient, and versatile sintering for various materials.

All About ACTIVATED CARBON THERMAL REGENERATION

Introduction, method and selection of activated carbon regeneration

The Future of Electrochemical Electrodes

The latest trends and developments in electrode materials and their implications for the future of electrochemistry.

Understanding the Isostatic Pressing Process: From Inception to Applications

The isostatic pressing process was pioneered in the mid-1950s and has steadily grown from a research curiosity to a viable production tool.Many industries apply this technique for the consolidation of powders or defect healing of castings. The process is used for a range of materials, including ceramics, metals, composites, plastics, and carbon.It has found wide application in industries for the consolidation of powders or defect healing of castings. It offers unique benefits for ceramic and refractory applications, allowing for the formation of product shapes to precise tolerances and reducing the need for costly machining.

Mastering Handheld Coating Thickness Gauges: A Comprehensive Guide for Industrial and Automotive Applications

Explore the intricacies of handheld coating thickness gauges, their applications in electroplating, automotive paint, and powder coatings. Learn how to choose and use these instruments effectively for quality control and cost efficiency.