Introduction: Importance of Electrochemical Electrodes

Electrochemical electrodes play a crucial role in various electrochemical applications, including batteries, fuel cells, and sensors. These electrodes are responsible for facilitating electron transfer reactions, and their efficiency and selectivity play a significant role in determining the overall performance of the electrochemical system. Improvements in electrode materials have led to significant gains in efficiency and selectivity, enabling more environmentally friendly and sustainable electrochemical processes. In this blog, we will explore the latest trends and developments in electrode materials and their implications for the future of electrochemistry.

Table of Contents

- Introduction: Importance of Electrochemical Electrodes

- Efficiency Gains in Electrode Materials

- Selectivity Changes Enabled by Electrode Materials

- Implications for Solvent Oxidation/Reduction

- Stability of Electrodes for Longevity and High Yields

- Need for Environmentally Friendly Materials in Electronics

- Conclusion: Utilization of Modified Electrodes

Efficiency Gains in Electrode Materials

Electrochemical electrodes play a crucial role in various fields, from energy production to healthcare. In recent years, there have been significant advancements in electrode materials, leading to considerable efficiency gains.

New Materials for Improved Electrodes

The use of new materials, such as graphene and nanotubes, has allowed for faster ion transfer and higher surface area, resulting in increased sensitivity and accuracy in electrochemical measurements. The new materials have also enabled the production of electrodes with lower resistivity and higher durability, thus increasing their lifespan.

Manufacturing Techniques for Enhanced Electrodes

Besides new materials, the development of new manufacturing techniques has enabled the production of enhanced electrodes with higher efficiency. With the help of new techniques, it is possible to fabricate electrodes with high surface area, low resistivity, and high durability.

The Future of Electrochemical Electrodes

The future of electrochemical electrodes is promising, with the potential for even greater efficiency gains as research continues. Advancements in materials science and nanotechnology are expected to lead to the development of new materials with even higher conductivity and lower costs, making electrochemical electrodes more accessible for a wider range of applications.

Integration of AI and Machine Learning

The integration of artificial intelligence and machine learning into electrochemical systems could lead to more precise and efficient data analysis, allowing for faster and more accurate measurements. This will not only improve the accuracy of electrochemical measurements but also reduce the time required for analysis.

In conclusion, the development of new materials and manufacturing techniques has significantly improved the efficiency of electrochemical electrodes. With the integration of AI and machine learning, we can expect greater accuracy and faster analysis of electrochemical measurements in the future.

Selectivity Changes Enabled by Electrode Materials

Electrodes are an essential component of any electrochemical system, and their selectivity is critical in various applications, including sensors, biosensors, and electrocatalysis. The future of electrochemical electrodes lies in the development of new materials that enable selectivity changes.

Nanomaterials for Enhancing Selectivity

The advancement in nanotechnology has made it possible to fabricate novel electrode materials with unique properties such as high surface area, high conductivity, and high selectivity. The use of nanomaterials such as graphene, carbon nanotubes, and metal nanoparticles has shown great potential in enhancing the selectivity of electrochemical electrodes. These materials offer a wide range of properties that can be tailored to specific applications. For example, graphene-based electrodes have high surface area and excellent conductivity, making them suitable for electrocatalysis applications.

Molecularly Imprinted Polymers (MIPs) for Selectivity

Another emerging trend in the fabrication of selective electrodes is the use of molecularly imprinted polymers (MIPs). MIPs are synthetic polymers that can selectively recognize and bind to a target molecule, which can be used as a recognition element in electrochemical sensors. MIPs provide high selectivity and sensitivity, making them ideal for various applications such as environmental monitoring and clinical diagnostics.

Importance of Stability and Reactivity

While selectivity is critical, the stability and reactivity of the electrode material are also essential. An electrode should be stable and resist corrosion, but at the same time, it should not be too resistant as it can cause an ohmic drop. Moreover, the mechanism for electron transfer at an electrode occurs between two limiting scenarios. The electrode surface can either be intimately involved in the mechanism of electron transfer, or it can be completely inert and provide a source or sink of electrons that are transferred in an outer-sphere manner between the substrate and electrode.

In conclusion, the development of new electrode materials with high selectivity will revolutionize the field of electrochemistry and pave the way for the development of new and advanced electrochemical devices with improved performance and sensitivity. The use of nanomaterials such as graphene, carbon nanotubes, and metal nanoparticles, and molecularly imprinted polymers (MIPs) in the fabrication of selective electrodes has shown great potential in enhancing the selectivity of electrochemical electrodes. However, while selectivity is critical, the stability and reactivity of the electrode material are also essential.

Implications for Solvent Oxidation/Reduction

Electrochemical electrodes have played an important role in various fields, including chemical analysis, energy storage, and conversion. Recently, there has been a growing interest in the use of electrochemical electrodes for solvent oxidation and reduction reactions. This development has significant implications for the future of energy conversion and storage, as well as environmental remediation.

Solvent Oxidation and Reduction

Solvent oxidation and reduction reactions can be used to convert chemical energy into electrical energy or vice versa. This process is highly efficient and has the potential to replace traditional combustion-based energy technologies. Furthermore, electrochemical electrodes can be used for environmental remediation, such as the removal of pollutants from water and air.

Advantages of Solvent Oxidation and Reduction

The use of solvent oxidation and reduction reactions has several advantages. Firstly, it is highly efficient and produces less waste compared to traditional combustion-based energy technologies. Secondly, it has the potential to be more sustainable and environmentally friendly. Lastly, it is highly versatile and can be used in various applications such as energy storage, conversion, and environmental remediation.

Role of Electrochemical Electrodes in Solvent Oxidation and Reduction

Electrochemical electrodes play a critical role in solvent oxidation and reduction reactions. They act as catalysts to facilitate the transfer of electrons between the reactants and the products. This allows for the efficient conversion of chemical energy into electrical energy or vice versa.

Future of Electrochemical Electrodes in Solvent Oxidation and Reduction

The future of electrochemical electrodes in solvent oxidation and reduction reactions looks promising, with ongoing research and development aimed at improving their performance, durability, and cost-effectiveness. The development of new electrode materials, such as graphene and nanotubes, is expected to further improve the efficiency and versatility of electrochemical electrodes in solvent oxidation and reduction reactions.

Conclusion

In conclusion, the use of electrochemical electrodes for solvent oxidation and reduction reactions has significant implications for the future of energy conversion and storage, as well as environmental remediation. The future of electrochemical electrodes looks bright, with ongoing research and development aimed at improving their performance, durability, and cost-effectiveness.

Stability of Electrodes for Longevity and High Yields

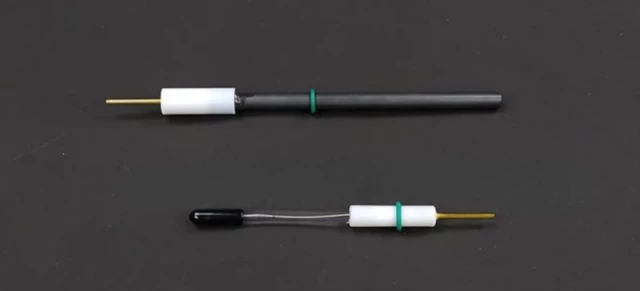

Electrochemical electrodes are critical for various scientific and industrial applications, including energy storage, biosensors, and corrosion prevention. However, their stability and durability remain a significant challenge. The longevity and yield of electrochemical electrodes are affected by several factors, including surface chemistry, microstructure, and composition.

Factors Affecting the Stability of Electrochemical Electrodes

The stability of electrochemical electrodes is influenced by various factors. One of the most crucial factors is surface chemistry. The surface chemistry of electrochemical electrodes affects their interaction with the electrolyte, which can impact their stability. Additionally, the microstructure of electrodes, such as their grain size, porosity, and crystal orientation, can also affect their stability.

The composition of electrodes is another essential factor that affects their stability. Electrodes made of materials that are susceptible to oxidation or reduction reactions can undergo significant structural changes during electrochemical cycling, leading to a loss of stability.

New Materials for Enhanced Stability and Performance

To enhance the longevity and yield of electrochemical electrodes, researchers are exploring new materials that offer improved stability and performance. One of the materials being studied is metal-organic frameworks (MOFs). MOFs offer high surface area, tunable pore size, and excellent stability, making them suitable for various electrochemical applications.

Nanomaterials are another class of materials that are being studied for electrode stability. Nanomaterials offer unique properties such as high surface area, enhanced electronic conductivity, and improved mechanical strength, making them ideal for electrochemical applications.

Polymers are also being explored as potential materials for electrode stability. Polymers offer excellent stability and mechanical strength, making them suitable for harsh environments.

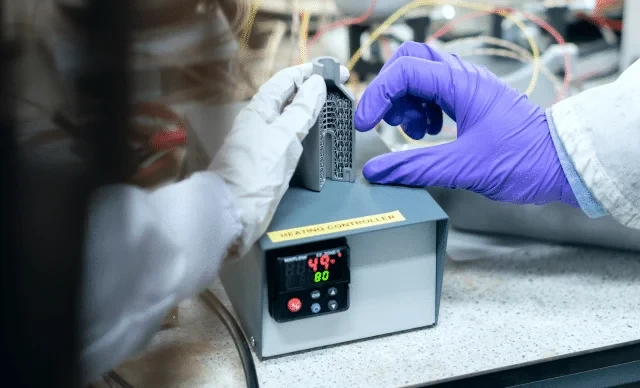

Advanced Manufacturing Techniques

Advances in manufacturing techniques such as 3D printing and electrospinning are enabling the production of complex electrode architectures that enhance durability and efficiency. 3D printing allows for the creation of unique electrode geometries that improve the electrode's performance. Electrospinning, on the other hand, allows for the creation of nanofibers that have high surface area and excellent mechanical strength, which can improve electrode stability.

Machine Learning and Artificial Intelligence

Machine learning and artificial intelligence (AI) are being used to optimize electrode design and performance. These technologies allow for the identification of the best descriptors and characteristics that enable tailored design of various electrolytes for specific uses. By exploring thousands of electrolyte possibilities with the aid of computation, researchers can significantly speed up their hunt for electrolyte breakthroughs.

Conclusion

In conclusion, the stability and durability of electrochemical electrodes remain a significant challenge that researchers are actively addressing. The use of new materials, advanced manufacturing techniques, and machine learning and AI is enabling the production of stable and durable electrodes that can withstand harsh environments and prolonged use. The future of electrochemical electrodes is bright, and their use is expected to continue playing a vital role in various fields, from healthcare to renewable energy, enabling groundbreaking discoveries and innovations.

Need for Environmentally Friendly Materials in Electronics

Introduction

Electrochemical electrodes are widely used in various electronic devices, such as glucose sensors, batteries, and fuel cells. However, the current materials used for these electrodes, such as platinum and other rare metals, have several environmental and economic drawbacks.

Drawbacks of Traditional Electrode Materials

The use of platinum and other rare metals in electrochemical electrodes has several environmental and economic drawbacks. These metals are not only expensive, but their mining and extraction processes are also harmful to the environment. Additionally, the limited supply of these metals makes it difficult to meet the growing demand for electronic devices.

Exploration of Alternative Materials

Several research studies have been conducted to explore the use of alternative materials, including carbon-based materials, graphene, and nanocellulose. These materials have shown promising results in terms of their electrochemical properties and sustainability.

Carbon-based Materials

Carbon-based materials, such as carbon nanotubes and graphene, have high conductivity, stability, and low toxicity, making them ideal for use in electrochemical electrodes. These materials are also abundant and can be synthesized in large quantities, making them a more sustainable alternative to traditional electrode materials.

Nanocellulose

Nanocellulose, a renewable and biodegradable material derived from plant matter, has also shown potential as a low-cost and sustainable alternative to traditional electrode materials. This material has high tensile strength and impressive thermal and electrical properties, making it suitable for use in electronic devices.

Advantages of Environmentally Friendly Materials

The use of environmentally friendly materials in electrochemical electrodes not only reduces the environmental impact of electronic devices but also ensures a reliable and sustainable supply chain for the manufacturing of these devices. Furthermore, the use of sustainable materials can result in cost savings for manufacturers, which can be passed on to consumers.

Conclusion

In conclusion, the future of electrochemical electrodes lies in the development of sustainable materials that can meet the increasing demand for electronic devices while minimizing their impact on the environment. The exploration of alternative materials, such as carbon-based materials and nanocellulose, shows promising results in terms of their electrochemical properties and sustainability. By using environmentally friendly materials, we can ensure a reliable and sustainable supply chain for the manufacturing of electronic devices.

Conclusion: Utilization of Modified Electrodes

In conclusion, modified electrodes have the potential to revolutionize the field of electrochemical electrodes. These electrodes can improve the efficiency and selectivity of electrochemical processes, while also providing a more environmentally friendly option for electronics. Carbon-based materials have emerged as promising candidates for modified electrodes due to their sustainability and efficiency gains. However, electrode selection must also consider practical and reactivity aspects. By understanding the mechanism for electron transfer at electrodes and the importance of overpotential in electrochemical processes, we can optimize the utilization of modified electrodes for longevity and high yields.

Related Products

- Electrolytic Electrochemical Cell for Coating Evaluation

- Electrode Fixture for Electrochemical Experiments

- Gold Electrochemical Sheet Electrode Gold Electrode

- Metal Disc Electrode Electrochemical Electrode

- Glassy Carbon Electrochemical Electrode

Related Articles

- Advanced Techniques in Coating Evaluation Using Electrolytic Cells

- Handheld Coating Thickness Gauges: Accurate Measurement for Electroplating and Industrial Coatings

- Advanced Electrolytic Cell Techniques for Cutting-Edge Lab Research

- Understanding Saturated Calomel Reference Electrodes: Composition, Uses, and Considerations

- The Transparency Paradox: Mastering the Fragile Art of Electrolytic Cells