In simple terms, sputtering rate is the speed at which atoms are physically ejected from a target material during the sputtering process. It is a measure of how quickly the source material is eroded, typically quantified as the number of atomic layers removed from the target's surface per second. This rate is the primary factor that determines how quickly a thin film is deposited onto a substrate.

Sputtering rate is not just a measurement; it is the central control parameter of the entire deposition process. Understanding the factors that govern this rate—from the choice of material to the power you apply—is the key to moving from simply coating a surface to engineering a high-quality, functional thin film.

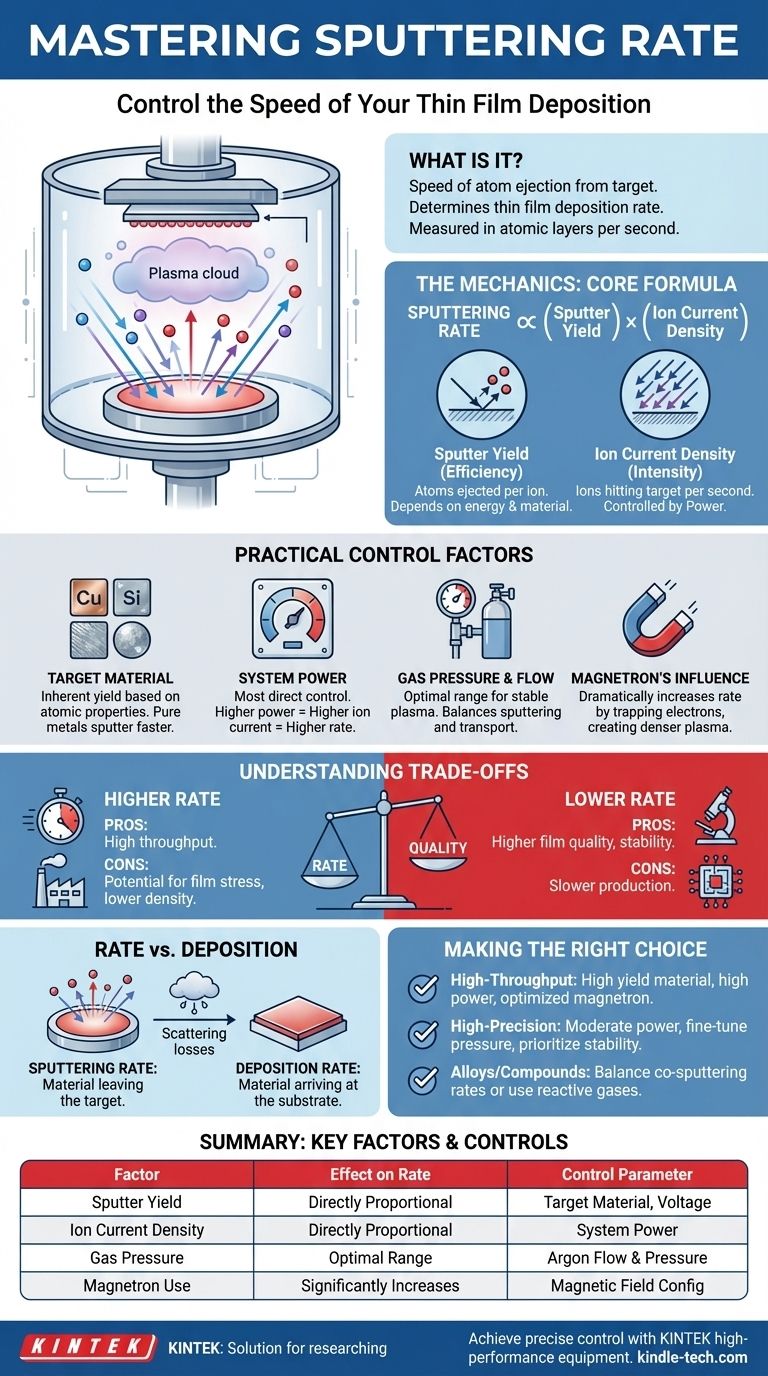

The Mechanics of Sputtering Rate

To effectively control the sputtering process, you must first understand the fundamental physics that dictate its speed. The rate is not arbitrary; it is a direct result of a few key variables.

The Core Formula

At its heart, the sputtering rate is a function of sputter yield, ion current density, and the physical properties of the target material. A simplified representation shows this relationship:

Sputtering Rate ∝ (Sputter Yield) x (Ion Current Density)

This means the rate is directly proportional to the efficiency of the sputtering event (yield) and the number of ions hitting the target (current).

The Role of Sputter Yield (S)

Sputter yield is the single most important efficiency metric in this process. It is defined as the average number of target atoms ejected for each single energetic ion that strikes the surface.

This yield is not a fixed constant. It depends heavily on the energy of the incoming ions (controlled by system voltage) and the atomic properties of both the ion (e.g., Argon) and the target material (e.g., Copper, Silicon).

The Importance of Ion Current Density (j)

Ion current density represents the quantity of sputtering ions striking a given area of the target per second. Think of it as the intensity of the "atomic sandblasting."

A higher ion current density means more bombarding particles are hitting the target, which directly leads to a higher sputtering rate. This is primarily controlled by the power supplied to the system.

Practical Factors That Control the Rate

While the physics provides the foundation, an operator controls the sputtering rate through several practical, adjustable parameters.

Target Material Properties

The material you choose to sputter has an inherent sputtering rate based on its atomic weight and surface binding energy. Some materials, like pure metals such as copper or iron, have naturally high sputter yields and are therefore sputtered very quickly, especially using DC power.

System Power

Power is the most direct control knob for sputtering rate. Increasing the power to the cathode (target) increases the density of the plasma. This, in turn, boosts the ion current density—more ions bombard the target, and the sputtering rate increases accordingly.

Gas Pressure and Flow

The sputtering process requires a vacuum chamber backfilled with an inert gas, typically Argon. The gas pressure must be low enough to allow sputtered atoms to travel to the substrate but high enough to sustain a stable plasma. An optimal pressure creates a uniform plasma and a stable, predictable sputtering rate.

The Magnetron's Influence

Modern systems almost exclusively use magnetron sputtering for a reason: it dramatically increases the rate. A magnetic field is placed behind the target to trap electrons near its surface.

These trapped electrons travel a long, helical path, vastly increasing the probability of them colliding with and ionizing the inert gas atoms. This creates a much denser plasma (and thus higher ion current density) right where it's needed, leading to a significantly higher sputtering rate at lower pressures compared to non-magnetron systems.

Understanding the Trade-offs

Achieving the highest possible sputtering rate is not always the best strategy. The rate you choose involves critical trade-offs that directly impact your final result.

Rate vs. Film Quality

A very high sputtering rate can be excellent for production throughput. However, it can sometimes lead to higher stress within the deposited film or a less dense microstructure. For sensitive optical or electronic applications, a slower, more controlled deposition often yields a higher-quality, more stable film.

Rate vs. Target Utilization

The magnetic field in a magnetron system creates a concentrated erosion area on the target, often called a "racetrack." While this concentration boosts the rate, an poorly designed magnetic pack may create a very deep, narrow racetrack. This leads to poor target utilization, as much of the expensive target material is left unsputtered while the center is depleted.

Sputtering Rate vs. Deposition Rate

It is crucial to distinguish between sputtering rate and deposition rate.

- Sputtering Rate: Material leaving the target.

- Deposition Rate: Material arriving at the substrate.

These two are not always the same. High gas pressure, for example, can increase plasma density and the sputtering rate, but it can also cause more of the sputtered atoms to be scattered by gas collisions before they reach the substrate, thereby lowering the deposition rate.

Making the Right Choice for Your Goal

Your optimal sputtering rate depends entirely on your objective. Use these principles as a guide to tune the process for your specific application.

- If your primary focus is high-throughput production: Use a material with a high sputter yield (like a pure metal), run at high power, and optimize your magnetron for a strong, uniform plasma to maximize the sputtering rate.

- If your primary focus is high-precision or R&D: Prioritize stability over speed. Use moderate power levels and fine-tune gas pressure to achieve a controlled, repeatable rate that produces the desired film properties.

- If your primary focus is depositing alloys or compounds: You must carefully balance the individual sputtering rates of multiple targets (co-sputtering) or reactively bleed in a gas (like Nitrogen or Oxygen), which will change the sputtering dynamics and rate.

Ultimately, mastering the sputtering rate is about understanding it as a tool to control the journey of atoms from your target to your substrate.

Summary Table:

| Factor | Effect on Sputtering Rate | Key Control Parameter |

|---|---|---|

| Sputter Yield (S) | Directly proportional | Target material, ion energy (voltage) |

| Ion Current Density (j) | Directly proportional | System power |

| Gas Pressure | Optimal range for stability | Argon flow and pressure |

| Magnetron Use | Significantly increases rate | Magnetic field configuration |

Ready to achieve precise control over your thin film deposition processes? KINTEK specializes in high-performance lab equipment and consumables for all your sputtering needs. Whether you're focused on high-throughput production or R&D precision, our experts can help you select the right system to optimize your sputtering rate and film quality. Contact our team today to discuss your specific laboratory requirements and discover how we can enhance your research and production outcomes.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Evaporation Boat for Organic Matter

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- What are the applications of ion beam sputtering? Achieve Unmatched Thin Film Quality for Demanding Applications

- What is the difference between a lab oven and a furnace? Choose the Right Tool for Your Thermal Process

- What are metal sintering processes? Unlock the Power of Powder Metallurgy

- What happens during sintering of ceramics? A Guide to Transforming Powder into Dense, Strong Parts

- How big is the chemical vapor deposition market? Projected to Reach $53.2 Billion by 2028

- What is the effect of pyrolysis temperature on bio-oil? Optimize Yield and Quality for Your Lab

- What is the grain size of sputter coating? Control Nanoscale Structure for Your Application

- What are the advantages and disadvantages of fluidized bed systems? Unlock Superior Process Efficiency