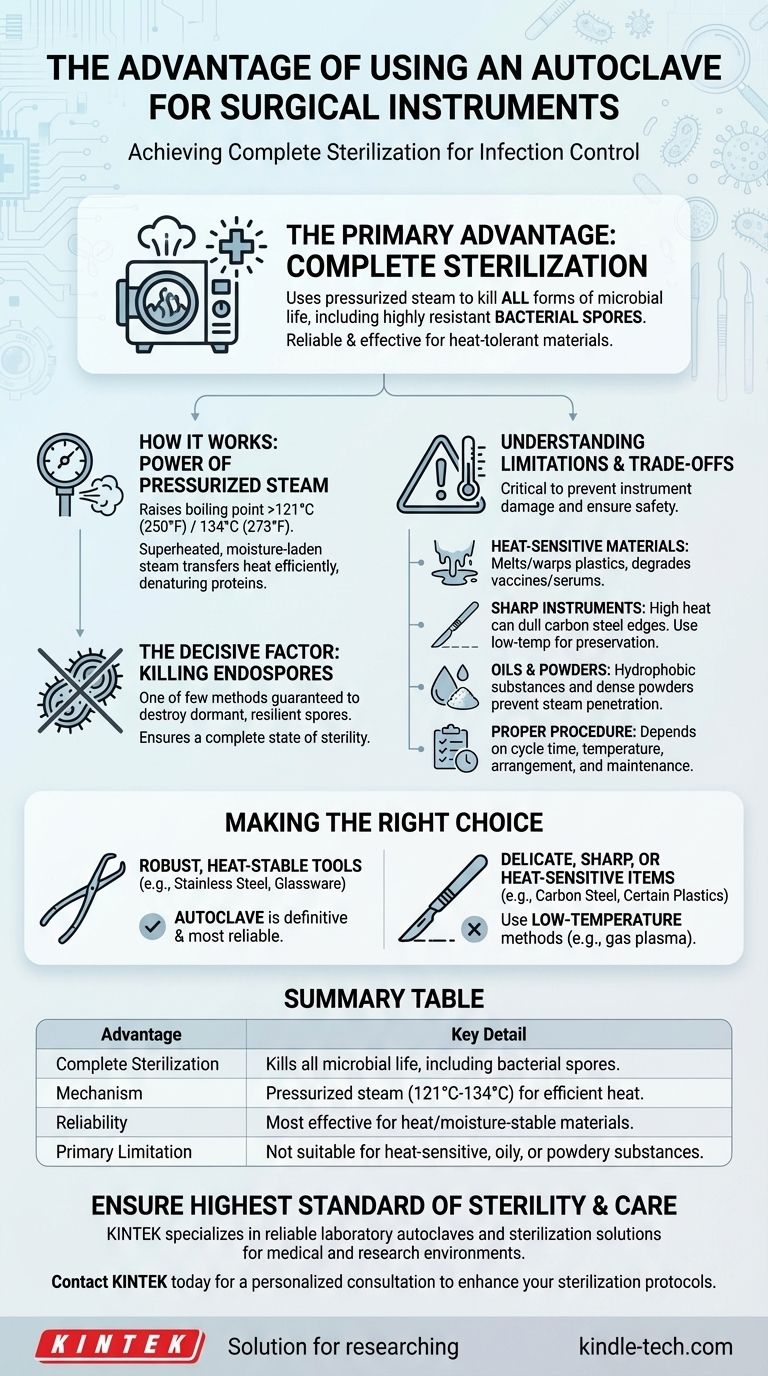

The primary advantage of using an autoclave is its ability to achieve complete sterilization by using pressurized steam to kill all forms of microbial life, including highly resistant bacterial spores. This method is exceptionally reliable and effective for any instruments and materials that can withstand high temperatures and moisture, making it a cornerstone of infection control in medical and laboratory settings.

An autoclave is the gold standard for sterilizing heat-tolerant materials because it reliably destroys even the most resilient microorganisms. However, its effectiveness is entirely dependent on correct usage, and it is fundamentally unsuitable for heat-sensitive instruments or water-repellent substances.

How Autoclaves Achieve Complete Sterilization

The effectiveness of an autoclave isn’t just about heat; it’s about the unique physical properties of steam under pressure. This combination allows it to achieve a level of microbial destruction that is difficult to match with other methods.

The Power of Pressurized Steam

By increasing the pressure inside its chamber, an autoclave raises the boiling point of water. This allows the steam to reach temperatures far higher than possible under normal atmospheric pressure, typically 121°C (250°F) or even 134°C (273°F).

This superheated, moisture-laden steam transfers thermal energy far more efficiently than dry heat, rapidly denaturing the essential proteins and enzymes that all microorganisms rely on to survive.

The Decisive Factor: Killing Endospores

Many disinfection methods can kill active bacteria and viruses. The true test of sterilization, however, is the ability to destroy bacterial endospores.

Spores are dormant, highly-protected structures produced by certain bacteria that can survive extreme conditions, including boiling and many chemical disinfectants. An autoclave's high-pressure steam is one of the few methods guaranteed to destroy these resilient spores, ensuring a complete state of sterility.

Understanding the Limitations and Trade-offs

While powerful, an autoclave is not a universal solution. Its reliance on high-temperature steam creates specific limitations that are critical to understand to prevent instrument damage and ensure procedural safety.

Unsuitability for Heat-Sensitive Materials

The most obvious limitation is its effect on materials that cannot tolerate high heat. Many plastics will melt or warp, compromising their integrity.

Furthermore, certain biological materials like vaccines, serums, and high-protein solutions will degrade or coagulate under intense heat. These items require alternative methods, such as sterile filtration.

The Risk to Sharp Instruments

High heat can have an adverse effect on the temper of metal, which is the property that gives it hardness and edge retention.

Sharp, high-grade carbon steel instruments, such as scalpel blades and some scissors, can become dulled by the repeated heating and cooling cycles of an autoclave. For these, alternative low-temperature sterilization methods are often preferred to preserve their cutting edge.

Ineffectiveness on Oils and Powders

The autoclave relies on steam to make direct contact with every surface. Oily or greasy substances are hydrophobic (water-repellent) and prevent steam from penetrating, leaving the material unsterilized.

Similarly, dense powders can trap air and resist steam penetration, making sterilization incomplete and unreliable.

The Criticality of Proper Procedure

The advantage of an autoclave is only realized when operated correctly. Secure sterilization demands strict adherence to protocol.

This includes using the correct cycle time and temperature for the specific load, arranging items to allow for steam circulation, and performing regular maintenance and calibration. Failure to do so can result in incomplete sterilization, creating a significant safety risk.

Making the Right Choice for Your Goal

To ensure both patient safety and the longevity of your instruments, you must match the sterilization method to the material being processed.

- If your primary focus is sterilizing robust, heat-stable tools (like stainless steel forceps, retractors, or glassware): The autoclave is the definitive and most reliable method available.

- If your primary focus is sterilizing delicate, sharp, or heat-sensitive items (like carbon steel scalpels, certain plastics, or electronics): You must use alternative low-temperature methods like gas plasma or chemical sterilization to avoid damage.

Ultimately, choosing the correct sterilization process is a critical decision that protects both your patient and your equipment.

Summary Table:

| Advantage | Key Detail |

|---|---|

| Complete Sterilization | Kills all microbial life, including highly resistant bacterial spores. |

| Mechanism | Uses pressurized steam for efficient heat transfer (typically 121°C-134°C). |

| Reliability | Considered the most effective method for heat/moisture-stable materials. |

| Primary Limitation | Not suitable for heat-sensitive items, oils, powders, or water-repellent substances. |

Ensure the highest standard of sterility and instrument care in your facility.

Choosing the right sterilization equipment is critical for patient safety and operational efficiency. KINTEK specializes in providing reliable laboratory autoclaves and sterilization solutions tailored to the rigorous demands of medical and research environments.

Our experts can help you select the perfect autoclave to meet your specific needs, ensuring effective infection control and protecting your valuable instrument investment.

Contact KINTEL today for a personalized consultation and discover how our lab equipment can enhance your sterilization protocols.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What are the do's and don'ts in using autoclave? A Guide to Safe and Effective Sterilization

- What is the importance of a Hastelloy high-pressure autoclave? Ensuring Precision in Nuclear Power Research

- What is the lowest temperature for sterilization? Methods for Heat-Sensitive Materials

- How are autoclaves checked and maintained? Ensure Sterilization Safety and Compliance

- What are the advantages of autoclave? Achieve Unmatched Sterilization Efficiency and Reliability

- How does the autoclave kill microorganisms? The Power of Pressurized Steam for Sterility

- What is the difference between 121 and 134 autoclave? Choose the Right Sterilization Cycle

- What is the most common machine used to sterilize medical supplies? The Definitive Guide to Autoclaves