While an autoclave is a primary sterilization tool, the most common alternatives are dry heat sterilization, chemical sterilization using gases like ethylene oxide (EtO), and radiation sterilization. An autoclave uses high-pressure steam to kill microorganisms, making it ideal for heat- and moisture-stable items. Alternatives are necessary for materials that would be damaged by these conditions.

The choice between an autoclave and an alternative is not about which is better overall, but which is appropriate for the specific material being sterilized. The critical decision factors are an item's tolerance for heat, moisture, pressure, and potential chemical or radiation exposure.

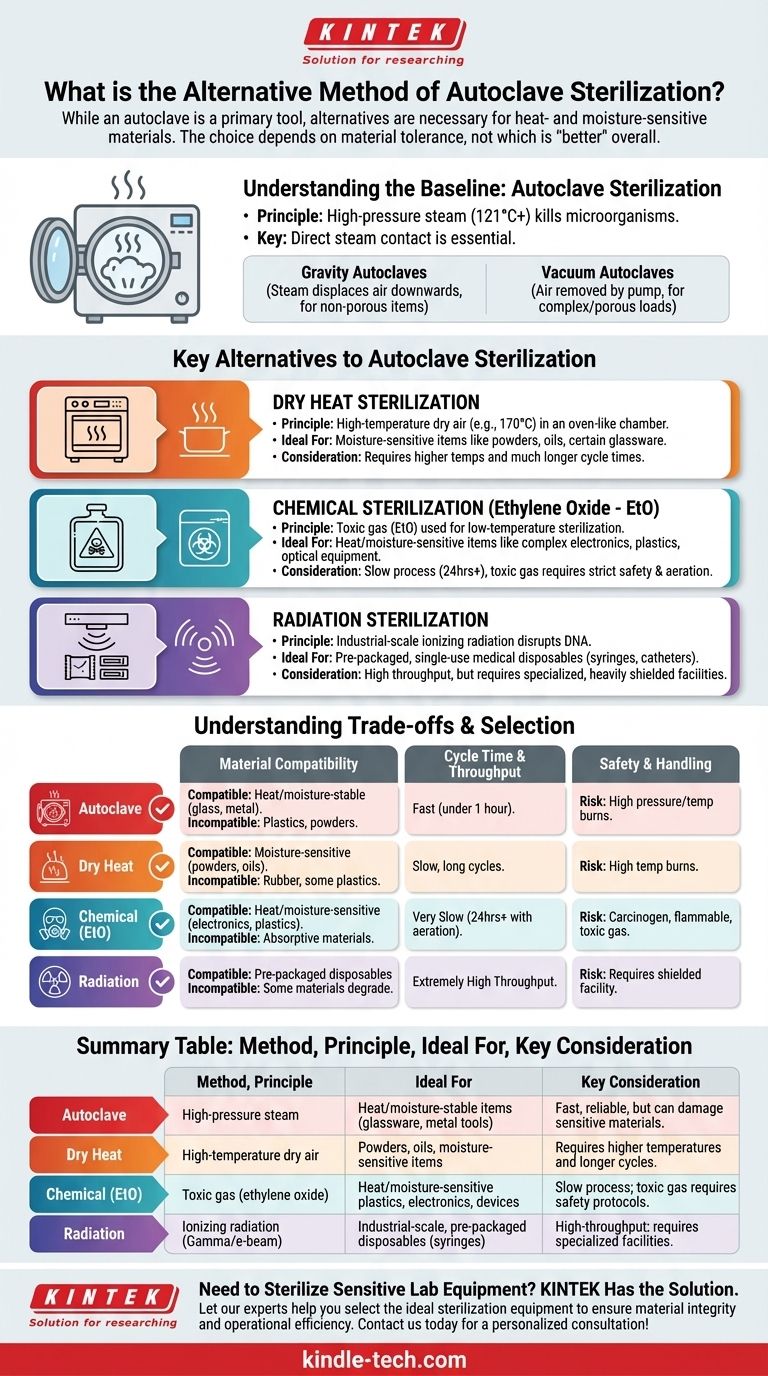

Understanding the Baseline: Autoclave Sterilization

Before exploring alternatives, it's essential to understand the principles of autoclave sterilization. This method is often the default choice in laboratory and medical settings due to its reliability and efficiency.

How Autoclaves Work

An autoclave is a pressure chamber that uses steam under high pressure to achieve sterilization temperatures, typically 121°C (250°F) or higher.

The combination of intense heat and moisture effectively denatures proteins in microorganisms, ensuring their destruction. The process relies on direct steam contact with every surface of the item.

Common Autoclave Methods

There are two primary types of autoclaves, distinguished by how they remove ambient air from the chamber.

- Gravity Autoclaves pump steam into the chamber, which is heavier than air and displaces it downwards. This method is effective for non-porous items like glassware and unwrapped metal instruments.

- Vacuum Autoclaves use a vacuum pump to actively remove all air before introducing steam. This ensures deep steam penetration, making it suitable for complex or porous loads like wrapped surgical kits and textiles.

Key Alternatives to Autoclave Sterilization

When items cannot withstand the high heat, pressure, or moisture of an autoclave, one of the following methods is typically employed.

Dry Heat Sterilization

This method uses an oven-like chamber to sterilize items with high-temperature dry air.

It requires higher temperatures (e.g., 170°C / 340°F) and much longer cycle times than autoclaving. It is the preferred method for materials that are sensitive to moisture, such as powders, oils, and certain types of glassware.

Chemical Sterilization (Ethylene Oxide)

Ethylene Oxide (EtO) is a toxic gas used for low-temperature sterilization.

This process is ideal for delicate instruments and devices that are sensitive to both heat and moisture, such as complex electronics, plastics, and optical equipment. Items are exposed to the gas in a sealed chamber under controlled conditions.

Radiation Sterilization

This industrial-scale method uses ionizing radiation (either Gamma rays or electron beams) to disrupt the DNA of microorganisms.

It is a low-temperature process perfect for pre-packaged, single-use medical supplies like syringes, sutures, and catheters. The radiation can penetrate final packaging, allowing for sterilization of fully sealed products.

Understanding the Trade-offs

Selecting a sterilization method requires a careful analysis of material compatibility, safety, and operational constraints. No single method is perfect for every application.

The Issue of Material Compatibility

This is the primary driver for choosing an alternative. Autoclaves can melt plastics, rust carbon steel instruments, and ruin moisture-sensitive powders. Dry heat can damage rubber or plastic components. EtO can be absorbed by certain materials, requiring lengthy aeration periods.

Cycle Time and Throughput

Autoclave cycles are relatively fast, often completed in under an hour. In contrast, EtO sterilization is a very slow process, potentially taking over 24 hours when factoring in the mandatory aeration period to remove residual toxic gas. Radiation offers extremely high throughput for industrial manufacturing.

Safety and Handling Concerns

Autoclaves present a risk of high-pressure and high-temperature burns if operated improperly. However, EtO gas is a known carcinogen and is highly flammable, requiring extensive safety protocols and specialized facilities. Radiation sterilization requires a heavily shielded facility inaccessible during operation.

Selecting the Right Sterilization Method

Your choice must align directly with the nature of the item you need to sterilize and your operational context.

- If you are sterilizing heat-stable, non-porous items (like glassware or standard metal tools): Autoclaving remains the most efficient, reliable, and cost-effective method.

- If you are sterilizing heat-sensitive plastics, complex medical devices, or electronics: Chemical sterilization with ethylene oxide (EtO) is the industry standard.

- If you are sterilizing powders, oils, or items that must remain absolutely dry: Dry heat sterilization is the appropriate choice.

- If you are sterilizing single-use medical disposables at an industrial scale: Radiation sterilization offers unparalleled efficiency for terminally sterilizing pre-packaged goods.

Ultimately, matching the sterilization method to the material's properties is the foundational principle for ensuring both product integrity and absolute sterility.

Summary Table:

| Method | Key Principle | Ideal For | Key Consideration |

|---|---|---|---|

| Autoclave | High-pressure steam | Heat/moisture-stable items (glassware, metal tools) | Fast, reliable, but can damage sensitive materials |

| Dry Heat | High-temperature dry air | Powders, oils, moisture-sensitive items | Requires higher temperatures and longer cycles |

| Chemical (EtO) | Toxic gas (ethylene oxide) | Heat/moisture-sensitive plastics, electronics, devices | Slow process; toxic gas requires safety protocols |

| Radiation | Ionizing radiation (Gamma/e-beam) | Industrial-scale, pre-packaged disposables (syringes) | High-throughput; requires specialized facilities |

Need to Sterilize Sensitive Lab Equipment? KINTEK Has the Solution.

Choosing the right sterilization method is critical for protecting your valuable laboratory materials and ensuring sterility. Whether you're working with delicate electronics, moisture-sensitive powders, or standard glassware, KINTEK specializes in providing the precise lab equipment—from autoclaves to ovens—that matches your specific needs.

Let our experts help you select the ideal sterilization equipment to ensure material integrity and operational efficiency.

Contact us today for a personalized consultation!

Visual Guide

Related Products

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What is the role of a hydrothermal autoclave in HAp nanosheet synthesis? Engineered High-Pressure Crystallization

- Why is a PTFE-lined laboratory autoclave required for CQDs? Ensure Purity in Hydrothermal Synthesis

- What are the disadvantages of autoclave in microbiology? Key Limitations for Lab Safety

- What is the primary function of a laboratory autoclave in the pre-treatment of medical plastic waste for liquid fuel?

- How do industrial autoclaves facilitate seed sludge heat treatment? Boost Bio-Hydrogen Yield & Purity

- What are the four components of sterilization? Master the Pillars of Effective Sterilization

- What precautions should be taken when using an autoclave in the laboratory? A Guide to Safe Sterilization

- What are the safety concerns when autoclaving? A Guide to Preventing Burns, Explosions, and Biohazards