In short, autoclaving is a sterilization method used in microbiology that employs high-pressure, saturated steam to eliminate all forms of microbial life, including bacteria, viruses, fungi, and resilient spores. It is the primary process for ensuring that lab equipment, culture media, and other materials are completely sterile before experiments and for decontaminating biohazardous waste before disposal.

The autoclave's core function is to create a controlled, sterile environment, which is the non-negotiable foundation for both reliable scientific results and laboratory safety. It serves the dual purpose of preparing a clean slate for experiments and safely cleaning up afterward.

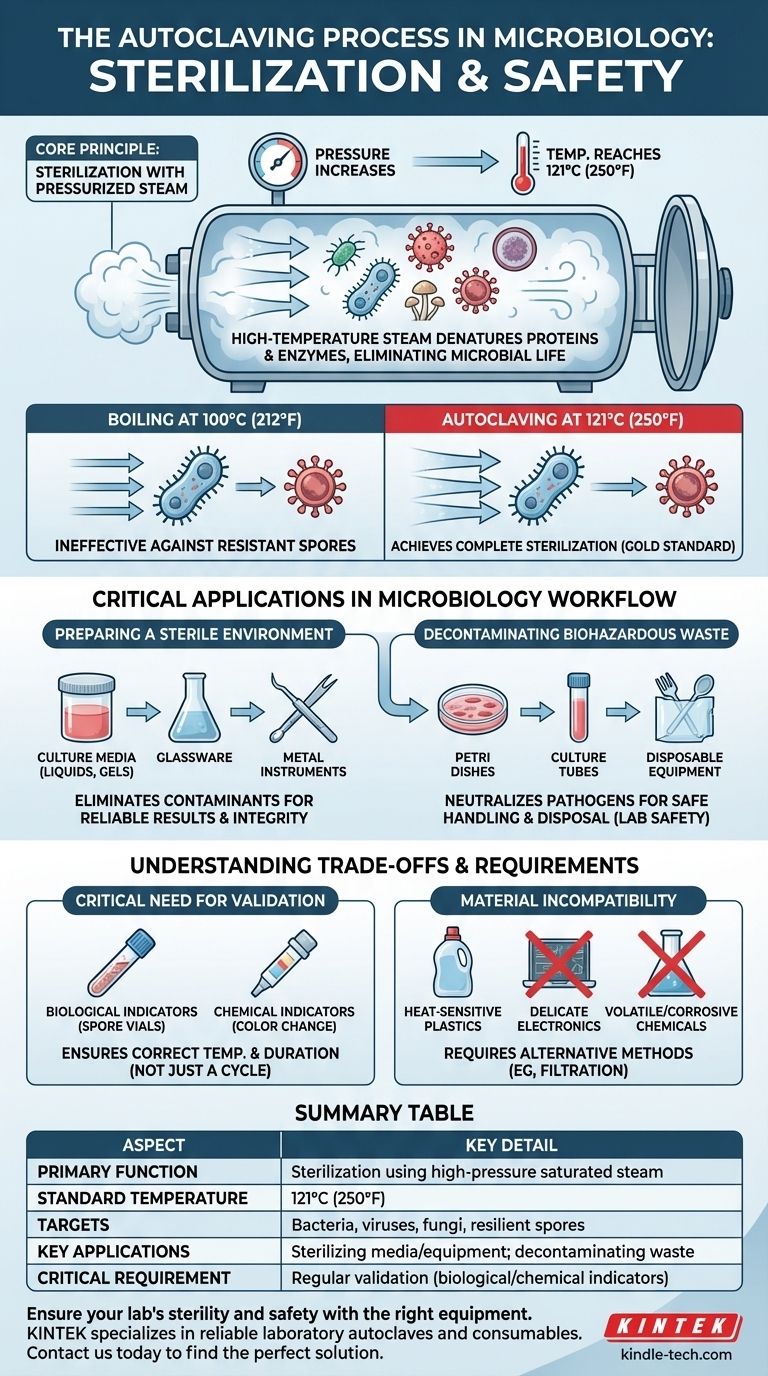

The Core Principle: Sterilization with Pressurized Steam

How It Works

The power of an autoclave does not come from pressure itself, but from the fact that pressure allows water to reach temperatures far above its normal boiling point.

By increasing the pressure inside a sealed chamber, the boiling point of water is elevated to 121°C (250°F) or higher. This high-temperature steam rapidly penetrates materials and denatures essential proteins and enzymes within microorganisms, effectively killing them.

Why It's More Effective Than Boiling

Simple boiling at 100°C (212°F) can kill many bacteria, but it is ineffective against the highly resistant spores that some bacteria form.

The intense heat achieved in an autoclave ensures the destruction of these spores, achieving a level of sterilization that boiling cannot match. This makes it a gold standard for critical applications.

Critical Applications in the Microbiology Workflow

The autoclave is a cornerstone of the daily lab routine, used at both the beginning and the end of the experimental lifecycle.

Preparing a Sterile Environment

To study a specific microorganism, you must ensure it is the only organism in your culture. Autoclaving is essential for sterilizing culture media (liquids, gels), glassware, and metal instruments.

This step eliminates any pre-existing contaminants that could interfere with your experiment, compete with your target organism, or produce misleading results. Without it, the integrity of microbiological research would be impossible to maintain.

Decontaminating Biohazardous Waste

After an experiment is complete, materials like petri dishes, culture tubes, and disposable equipment are contaminated with potentially infectious microorganisms.

Autoclaving this biohazardous waste is a critical safety procedure. It neutralizes all pathogens, rendering the waste safe for handling and disposal, thereby protecting lab personnel and preventing the release of microbes into the environment.

Understanding the Trade-offs and Requirements

While highly effective, the autoclaving process is not without its limitations and strict requirements for proper use.

The Critical Need for Validation

Simply running an autoclave cycle does not guarantee sterilization. The process must be regularly validated using biological indicators (vials containing highly resistant spores) or chemical indicators that change color upon reaching the correct temperature.

Validation confirms that the autoclave is reaching the necessary temperature for the required duration to achieve complete sterilization, ensuring both safety and experimental reliability.

Material Incompatibility

The high heat and pressure will destroy or damage certain materials. Heat-sensitive items, such as some plastics, delicate electronics, and volatile or corrosive chemicals, cannot be autoclaved.

For these items, alternative sterilization methods like filtration, chemical sterilization, or irradiation must be used. Choosing the correct method is crucial for preserving the integrity of your equipment.

Making the Right Choice for Your Goal

Proper use of an autoclave is fundamental to good laboratory practice. Your primary objective will determine how you prioritize its function.

- If your primary focus is reliable experimental results: Use autoclaving to guarantee that your culture media, reagents, and instruments are completely free of contaminants before you begin.

- If your primary focus is laboratory safety: Implement and validate a strict autoclaving protocol for decontaminating all biohazardous materials before they leave the lab.

Ultimately, mastering the autoclaving process is essential for anyone committed to performing safe, accurate, and reproducible science.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Function | Sterilization using high-pressure saturated steam |

| Standard Temperature | 121°C (250°F) |

| Targets | Bacteria, viruses, fungi, and resilient spores |

| Key Applications | Sterilizing culture media/equipment; decontaminating biohazardous waste |

| Critical Requirement | Regular validation with biological/chemical indicators |

Ensure your lab's sterility and safety with the right equipment. KINTEK specializes in reliable laboratory autoclaves and consumables designed for the rigorous demands of microbiology. Our solutions help you achieve precise sterilization for uncontaminated experiments and safe waste disposal, protecting your research and your team.

Contact us today to find the perfect autoclave solution for your laboratory's needs.

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- Why is a high-pressure hydrothermal autoclave core for g-C3N4/CeO2? Achieve Powerful Heterojunction Synthesis

- What is the function of high-pressure hydrothermal autoclaves in catalyst synthesis? Achieve Superior Nano-Architectures

- Why is a Nickel-based alloy typically selected for the high-pressure autoclave? Ensure Safety & Precision in S-CO2 Testing

- What is the principle of autoclave quizlet? Master the Science of Steam Sterilization

- What are the common uses of autoclave? Achieve Absolute Sterility for Safety and Precision

- What are the methods of validation of autoclave? Ensure Sterility with a 3-Pillar Approach

- How does autoclave work step by step? A Guide to Reliable Sterilization

- What role does a high-pressure hydrothermal autoclave play in 3D-GO synthesis? Optimize Your Graphene Composites