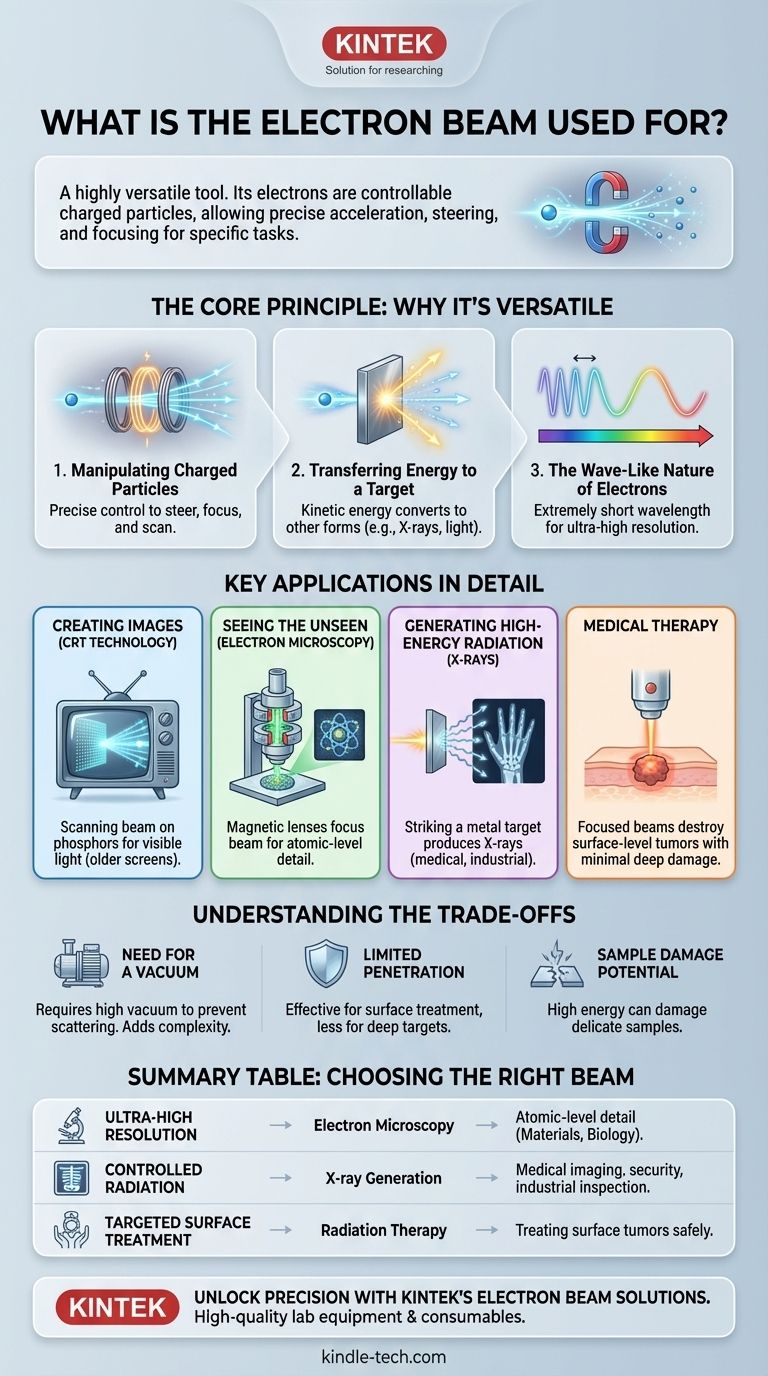

At its core, an electron beam is a highly versatile tool used across research, technology, and medicine. Its primary applications involve generating high-energy radiation like X-rays, creating images on screens like older televisions and oscilloscopes, and enabling ultra-high-resolution imaging in electron microscopes.

The immense utility of an electron beam stems from a simple fact: electrons are charged particles. This charge allows them to be precisely accelerated, steered, and focused using electric and magnetic fields, making them a controllable form of energy that can be directed to perform specific tasks.

The Core Principle: Why an Electron Beam is So Versatile

To understand its applications, you must first grasp the fundamental properties of the electron beam itself. Its usefulness isn't accidental; it's a direct result of physics.

Manipulating Charged Particles

An electron beam is essentially a stream of electrons fired from a source. Because each electron carries a negative charge, the entire beam can be manipulated with incredible precision by external electric and magnetic fields.

This control allows operators to steer the beam, focus it to a pinpoint, and scan it across a surface, similar to how a painter directs a brush.

Transferring Energy to a Target

Electrons in a beam are accelerated to very high speeds, meaning they carry significant kinetic energy. When this beam strikes a target material, that energy is transferred and converted into other forms.

This energy conversion is the basis for many applications, whether it's generating light from a phosphor screen or producing X-rays from a metal target.

The Wave-Like Nature of Electrons

According to quantum mechanics, particles like electrons also behave like waves. The wavelength of a high-energy electron is thousands of times shorter than that of visible light.

This extremely short wavelength is what allows electron microscopes to resolve details far smaller than any optical microscope ever could.

Key Applications in Detail

The principles of control, energy transfer, and short wavelength unlock a wide range of powerful technologies that have shaped the modern world.

Creating Images (CRT Technology)

In older cathode-ray tube (CRT) televisions and oscilloscopes, an electron beam was rapidly scanned across the back of a screen coated in phosphors.

When the electrons struck the phosphors, their energy was converted into visible light, "painting" an image line by line, faster than the human eye could perceive.

Seeing the Unseen (Electron Microscopy)

Electron microscopes use magnetic fields as "lenses" to focus a beam of electrons onto or through a specimen.

By detecting how these electrons interact with the sample, scientists can construct images with atomic-level detail, revolutionizing fields from biology to materials science.

Generating High-Energy Radiation (X-rays)

When a high-energy electron beam is fired at a dense metal target (like tungsten), the electrons decelerate rapidly. This sudden loss of energy is released in the form of X-rays.

This is the foundational technology behind medical X-ray imaging, security scanners, and industrial inspection equipment.

Medical Therapy

In radiation therapy, focused beams of high-energy electrons can be used directly to target and destroy cancerous tumors.

Because electrons deposit their energy over a relatively short distance, this technique is particularly effective for treating cancers on or near the skin's surface with minimal damage to deeper tissues.

Understanding the Trade-offs

While powerful, electron beam technology has inherent requirements and limitations that dictate where it can be effectively used.

The Need for a Vacuum

Electron beams are easily scattered by molecules in the air. Therefore, almost all applications require the beam to travel within a high-vacuum chamber, which adds significant cost and complexity to the equipment.

Limited Penetration Depth

For direct applications like medical therapy or material sterilization, electron beams do not penetrate materials as deeply as X-rays do. This is an advantage for treating surface tumors but a limitation for deep targets.

Potential for Sample Damage

The same high energy that makes electron beams useful can also damage or destroy delicate samples, particularly in electron microscopy. This often requires complex sample preparation techniques like flash-freezing to preserve the structure.

How Electron Beams Are Chosen for a Task

The decision to use an electron beam is based entirely on the specific goal of the application, leveraging its unique properties.

- If your primary focus is ultra-high-resolution imaging: The incredibly short wavelength of electrons makes an electron microscope the only viable choice for seeing atomic-scale detail.

- If your primary focus is generating controlled radiation: An electron beam is the most efficient method for producing X-rays for medical and industrial imaging by striking a metal target.

- If your primary focus is targeted, surface-level medical treatment: The limited penetration depth of a direct electron beam makes it ideal for irradiating tumors near the skin without damaging underlying organs.

Ultimately, the ability to precisely control the energy and position of electrons makes the electron beam a fundamental and irreplaceable tool in modern science and technology.

Summary Table:

| Application | Key Function | Primary Use Case |

|---|---|---|

| Electron Microscopy | Ultra-high-resolution imaging | Viewing atomic-level details in materials science & biology |

| X-ray Generation | Producing high-energy radiation | Medical imaging, security scanners, industrial inspection |

| CRT Displays | Creating images on screens | Older televisions, oscilloscopes |

| Radiation Therapy | Targeted cancer treatment | Destroying surface-level tumors with minimal deep tissue damage |

Unlock Precision with KINTEK's Electron Beam Solutions

Are you working in a laboratory that requires cutting-edge electron beam technology for research, analysis, or materials processing? KINTEK specializes in high-quality lab equipment and consumables tailored to meet the demanding needs of modern laboratories.

We provide reliable solutions that help you achieve superior results in imaging, spectroscopy, and material modification. Let our expertise support your projects with equipment that ensures accuracy, efficiency, and durability.

Contact us today via our form to discuss how KINTEK can enhance your lab's capabilities and drive your innovations forward.

Visual Guide

Related Products

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Platinum Auxiliary Electrode for Laboratory Use

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

- Rotating Platinum Disk Electrode for Electrochemical Applications

People Also Ask

- What is sputtering in plasma treatment? A Guide to High-Purity Thin Film Deposition

- What is direct current DC magnetron sputtering? A Guide to High-Quality Thin Film Deposition

- What is the fundamental of magnetron sputtering? Master High-Quality Thin Film Deposition

- What is sputtering technology? A Guide to Precision Thin Film Deposition

- How does a magnetron sputtering work? A Guide to High-Quality Thin Film Deposition