The most effective and safest sterilization method is not a single technique, but rather the one best matched to the specific material and its intended application. While steam sterilization via an autoclave is widely considered the gold standard for its unparalleled reliability, speed, and non-toxic nature, it is completely unsuitable for items sensitive to heat and moisture. Therefore, the "best" method is a situational decision.

The core principle of sterilization is choosing a method that achieves a complete kill of all microorganisms without damaging the item being sterilized. This creates a fundamental trade-off between the high efficacy of thermal methods and the material compatibility offered by chemical, radiation, or filtration techniques.

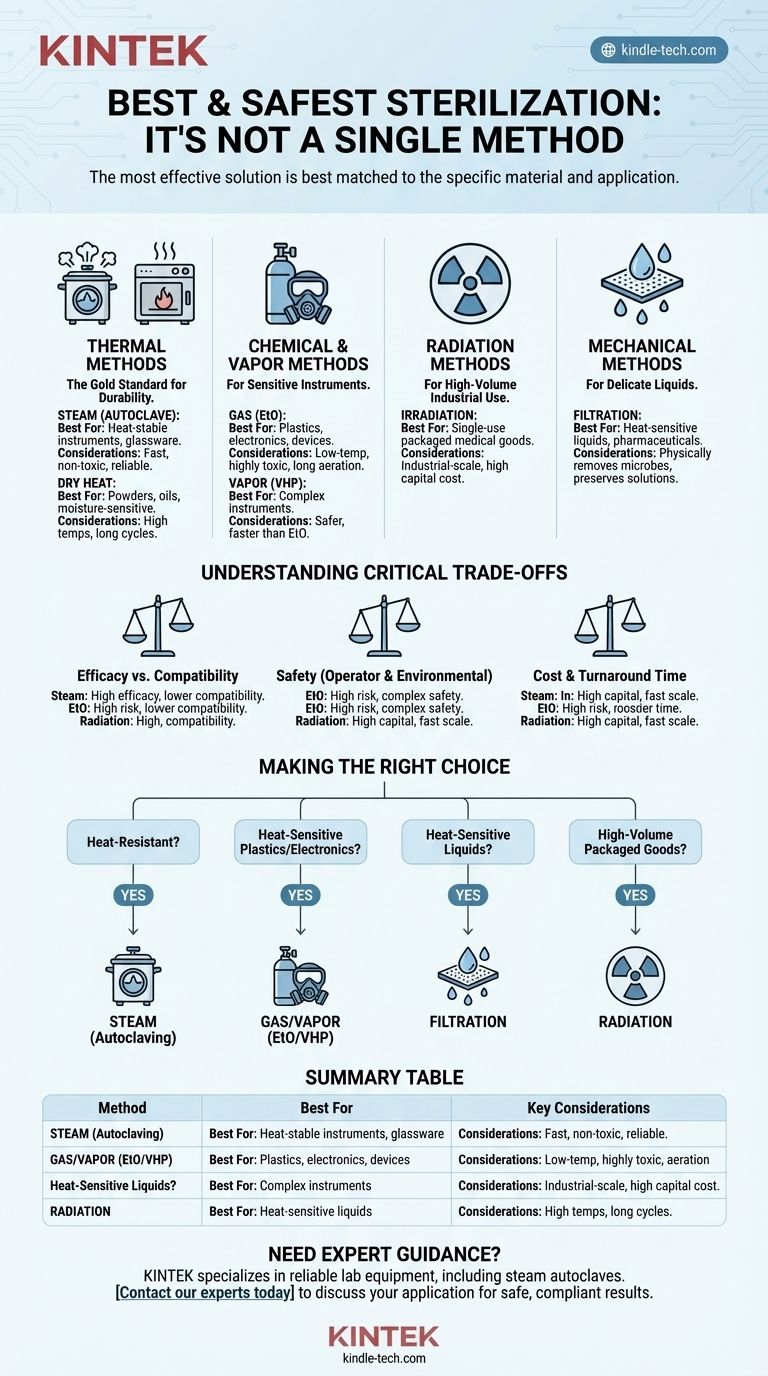

The Primary Categories of Sterilization

To make an informed choice, you must first understand the fundamental approaches to sterilization. They are typically grouped by their mechanism of action: thermal, chemical, radiation, and physical removal.

Thermal Methods: The Gold Standard for Durability

Thermal sterilization uses high heat to denature the essential proteins of microorganisms. It is highly effective, reliable, and generally inexpensive.

Steam Sterilization (Autoclave) An autoclave uses pressurized steam to reach high temperatures (typically 121-134°C). This combination of heat and moisture is extremely effective at killing all microbes, including resilient bacterial spores.

It is the preferred method for sterilizing most surgical instruments, laboratory glassware, and other heat-stable materials due to its speed and lack of toxic residues.

Dry Heat Sterilization This method uses an oven to generate hot, dry air. It requires higher temperatures and much longer exposure times than steam because dry heat penetrates more slowly.

Dry heat is best suited for materials that can be damaged by moisture, such as powders, oils, and certain metal instruments that are prone to rust.

Chemical & Vapor Methods: For Sensitive Instruments

When an item cannot withstand high heat, chemical sterilization is the necessary alternative. These methods use reactive gases or vapors to destroy microorganisms at lower temperatures.

Gas Sterilization (Ethylene Oxide - EtO) Ethylene Oxide (EtO) gas is a highly effective sterilant that can permeate plastics and other materials to kill microbes. It is a critical process for many heat-sensitive medical devices, including electronics and certain polymers.

However, EtO is toxic and carcinogenic, requiring long aeration cycles to remove residual gas and stringent safety protocols for operators.

Vapor Sterilization (VHP) Vaporized Hydrogen Peroxide (VHP) is another low-temperature method that is effective for sterilizing complex instruments. It breaks down into non-toxic water and oxygen, making it safer than EtO with faster turnaround times.

Radiation Methods: For High-Volume Industrial Use

Radiation sterilization uses gamma rays or electron beams to disrupt the DNA of microorganisms, preventing them from reproducing.

Irradiation This is a highly effective, low-temperature method used primarily for the industrial-scale sterilization of single-use medical products like syringes, gloves, and catheters after they have been packaged. The capital cost of the equipment is extremely high, limiting its use to large-scale manufacturers.

Mechanical Methods: For Delicate Liquids

This category stands apart because it does not kill microbes but physically removes them.

Sterilization by Filtration This process involves passing a liquid or gas through a filter with pores small enough to trap microorganisms. It is the only method suitable for sterilizing heat-labile solutions, such as pharmaceuticals or cell culture media, without destroying their chemical composition.

Understanding the Critical Trade-offs

Choosing a method requires balancing efficacy against potential downsides. No single method is perfect for every situation.

Efficacy vs. Material Compatibility

This is the most common trade-off. Steam autoclaving offers the highest assurance of sterility for items that can withstand it. For plastics, electronics, or delicate optics, a less aggressive low-temperature method like EtO or VHP must be used, which introduces its own set of complexities.

Operator and Environmental Safety

The safety profile of each method varies dramatically. Steam uses only water, making it inherently safe for operators and the environment. In contrast, gas sterilization with EtO requires extensive engineering controls and monitoring to protect workers from exposure to a toxic gas.

Cost and Turnaround Time

An autoclave cycle can be completed in under an hour. An EtO sterilization cycle can take over 12 hours due to the long aeration phase required to ensure the device is safe for patient contact. Radiation is fast and efficient at scale but requires a massive initial investment.

Making the Right Choice for Your Application

Your selection must be guided by the material you are sterilizing and its final purpose.

- If your primary focus is heat-resistant surgical instruments or lab glassware: Steam sterilization (autoclaving) is the most reliable, cost-effective, and safest choice.

- If your primary focus is heat-sensitive plastics or medical electronics: Low-temperature gas or vapor sterilization (EtO or VHP) is necessary, but requires strict adherence to safety protocols.

- If your primary focus is sterilizing heat-sensitive liquids like pharmaceuticals: Sterilization by filtration is the only method that preserves the product while ensuring sterility.

- If your primary focus is high-volume, single-use packaged goods: Radiation offers unparalleled efficiency for industrial-scale sterilization.

Ultimately, a thorough risk assessment of your specific item is the foundation of any safe and effective sterilization strategy.

Summary Table:

| Method | Best For | Key Considerations |

|---|---|---|

| Steam (Autoclave) | Heat-stable instruments, glassware | Gold standard for efficacy; fast, non-toxic |

| Dry Heat | Powders, oils, moisture-sensitive items | High temperatures, long cycle times |

| Gas (EtO/VHP) | Plastics, electronics, sensitive devices | Low-temperature; requires safety protocols |

| Radiation | High-volume, single-use packaged goods | Industrial-scale; high capital cost |

| Filtration | Heat-sensitive liquids, pharmaceuticals | Physically removes microbes; preserves solutions |

Need expert guidance on selecting the right sterilization equipment for your laboratory?

Choosing the correct sterilization method is critical for the safety of your personnel and the integrity of your materials. KINTEK specializes in providing reliable lab equipment and consumables, including autoclaves for steam sterilization and solutions for your specific laboratory needs.

Contact our experts today to discuss your application and ensure you achieve effective, safe, and compliant sterilization results.

Visual Guide

Related Products

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam

- What role does an autoclave play in remediation experiments? Ensure Precision by Eliminating Biological Noise

- What role does a laboratory autoclave play in the separation of lignin? High-Purity Extraction for Biomass Research

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization