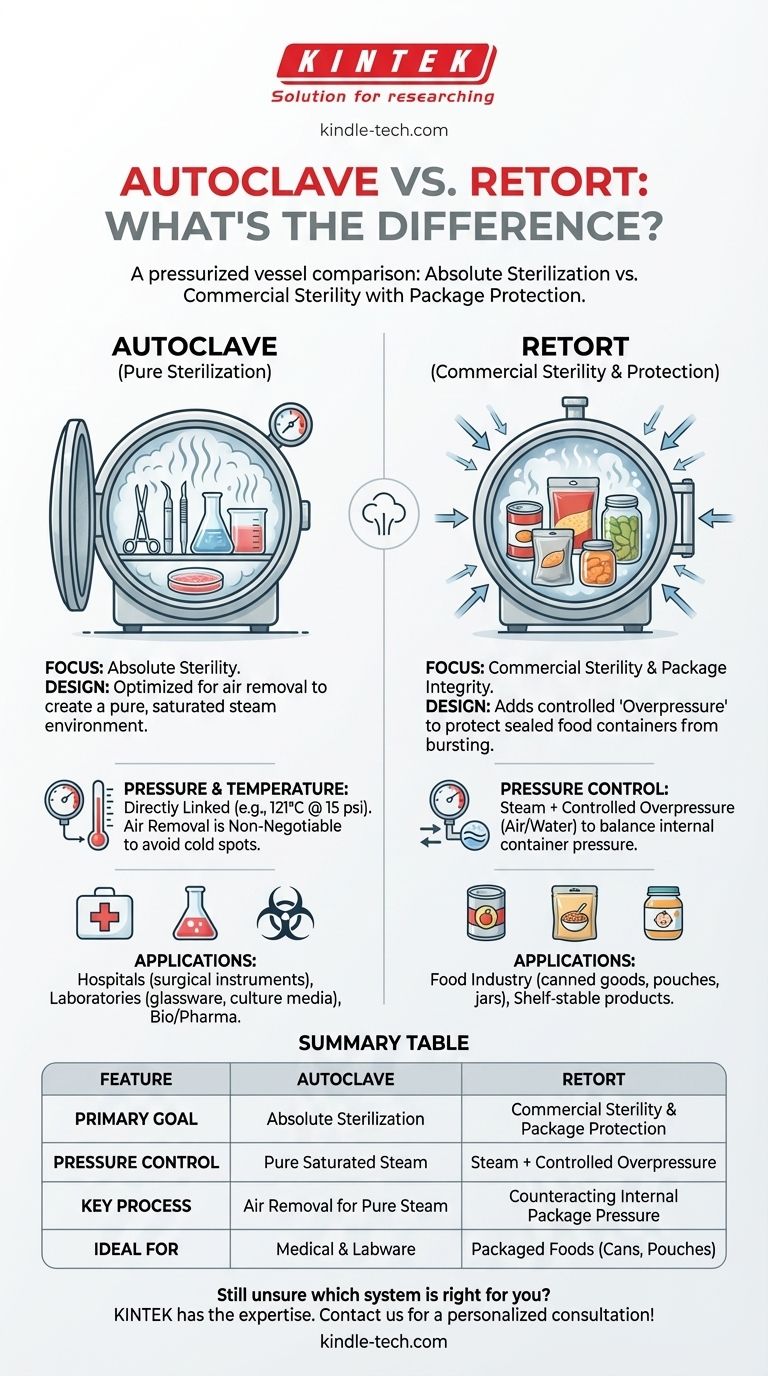

At first glance, both an autoclave and a retort appear to be the same device: a pressurized vessel that uses steam to heat its contents. The critical difference, however, lies not just in their hardware but in their fundamental purpose and method of pressure control. An autoclave uses pure, saturated steam where pressure and temperature are directly linked, designed exclusively for total sterilization. A retort adds controlled "overpressure" (typically with compressed air or water) to protect the integrity of sealed food packaging during the sterilization process.

The core distinction is one of intent. An autoclave's only goal is to achieve absolute sterility. A retort's goal is to achieve commercial sterility while simultaneously preventing the sealed food container from bursting or failing.

What is an Autoclave? The Focus on Pure Sterilization

An autoclave is a precision instrument designed to kill all forms of microbial life, including resilient bacterial spores. Its operation is governed by the physical properties of steam.

The Power of Saturated Steam

The key to an autoclave's effectiveness is its use of saturated steam. After placing items inside and sealing the chamber, a vacuum pump removes the air. This is a critical step.

Steam is then injected. In an air-free environment, the chamber's pressure is generated only by the water vapor. This creates a direct, predictable relationship between pressure and temperature, ensuring that every surface reaches the target sterilization temperature (e.g., 121°C / 250°F at 15 psi).

Why Air Removal is Non-Negotiable

If air is trapped inside the chamber, it creates "cold spots." Air acts as an insulator, preventing steam from directly contacting surfaces and transferring its heat effectively.

This would lead to failed sterilization cycles. Therefore, the design of an autoclave is entirely optimized to displace or remove air to guarantee a pure steam environment.

Primary Applications

Autoclaves are the gold standard in environments where absolute sterility is paramount. This includes:

- Hospitals and clinics for sterilizing surgical instruments.

- Laboratories for sterilizing glassware and culture media.

- Biotechnology and pharmaceutical manufacturing.

What is a Retort? The Focus on Commercial Sterility

A retort is an industrial-scale pressure vessel that also uses steam for heating, but it solves a different and more complex problem: making packaged food shelf-stable.

The Challenge of Packaged Foods

When a sealed container of food—like a can, glass jar, or flexible pouch—is heated, the contents expand and generate significant internal pressure.

If this container were heated in a pure-steam autoclave, the internal pressure would vastly exceed the external pressure, causing the container to deform, burst, or lose its seal.

The Role of Overpressure

This is where the retort's unique capability comes in. A retort introduces a secondary medium, typically compressed air or superheated water, to create overpressure.

This external overpressure is precisely controlled to counteract the rising internal pressure of the food package. It acts as a protective cushion, keeping the container intact throughout the heating and cooling cycle.

Primary Applications

Retorts are the workhorses of the food industry. They are used for producing shelf-stable products like:

- Canned vegetables, soups, and meats.

- Ready-to-eat meals in flexible pouches.

- Baby food in glass jars.

Understanding the Trade-offs

Choosing between these devices requires understanding their inherent design compromises.

Process Control: Simplicity vs. Complexity

An autoclave's control system is relatively simple, focused on maintaining a specific temperature-pressure curve for a set time.

A retort's control system is far more complex. It must simultaneously manage temperature profiles and dynamic overpressure profiles, which change depending on the type of food and packaging being processed.

Packaging Integrity: The Deciding Factor

You cannot reliably process sealed, flexible, or fragile containers in a standard autoclave. The lack of overpressure will almost certainly lead to package failure.

A retort is explicitly designed to protect the package. This is its primary advantage and purpose in the food industry.

Efficiency and Medium

Autoclaves are highly efficient for sterilizing solid, unwrapped goods because pure steam has excellent heat transfer properties. Retorts, especially water spray or immersion types, can offer very uniform and rapid heating for packaged goods but may have different energy consumption profiles.

Making the Right Choice for Your Goal

Your application dictates the correct tool. The choice is not about which is "better," but which is designed for your specific process.

- If your primary focus is sterilizing medical instruments, lab equipment, or biological waste: You require the validated, pure-steam process of an autoclave.

- If your primary focus is producing shelf-stable packaged foods like cans, pouches, or jars: You require the controlled overpressure of a retort to ensure both food safety and package integrity.

- If your primary focus is research using high-pressure steam on non-sealed materials: An autoclave is likely the correct and more cost-effective tool.

Choosing the right vessel ensures not just the success of your process, but the safety and integrity of your final product.

Summary Table:

| Feature | Autoclave | Retort |

|---|---|---|

| Primary Goal | Absolute Sterilization | Commercial Sterility & Package Protection |

| Pressure Control | Pure Saturated Steam | Steam + Controlled Overpressure (Air/Water) |

| Key Process | Air Removal for Pure Steam | Counteracting Internal Package Pressure |

| Ideal For | Medical Instruments, Labware | Canned Foods, Pouches, Jars |

Still unsure which system is right for your process?

Whether your priority is achieving absolute sterility for medical or lab applications with an autoclave, or ensuring the safety and integrity of your packaged food products with a retort, KINTEK has the expertise and equipment to meet your needs. We specialize in providing reliable lab equipment and consumables tailored to your specific laboratory or production challenges.

Let our experts guide you to the perfect solution. Contact us today for a personalized consultation!

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- Why is the standard autoclave temperature set to 121? The Science of Effective Sterilization

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- What types of items and materials can be processed in a laboratory autoclave? Essential Guide for Lab Safety