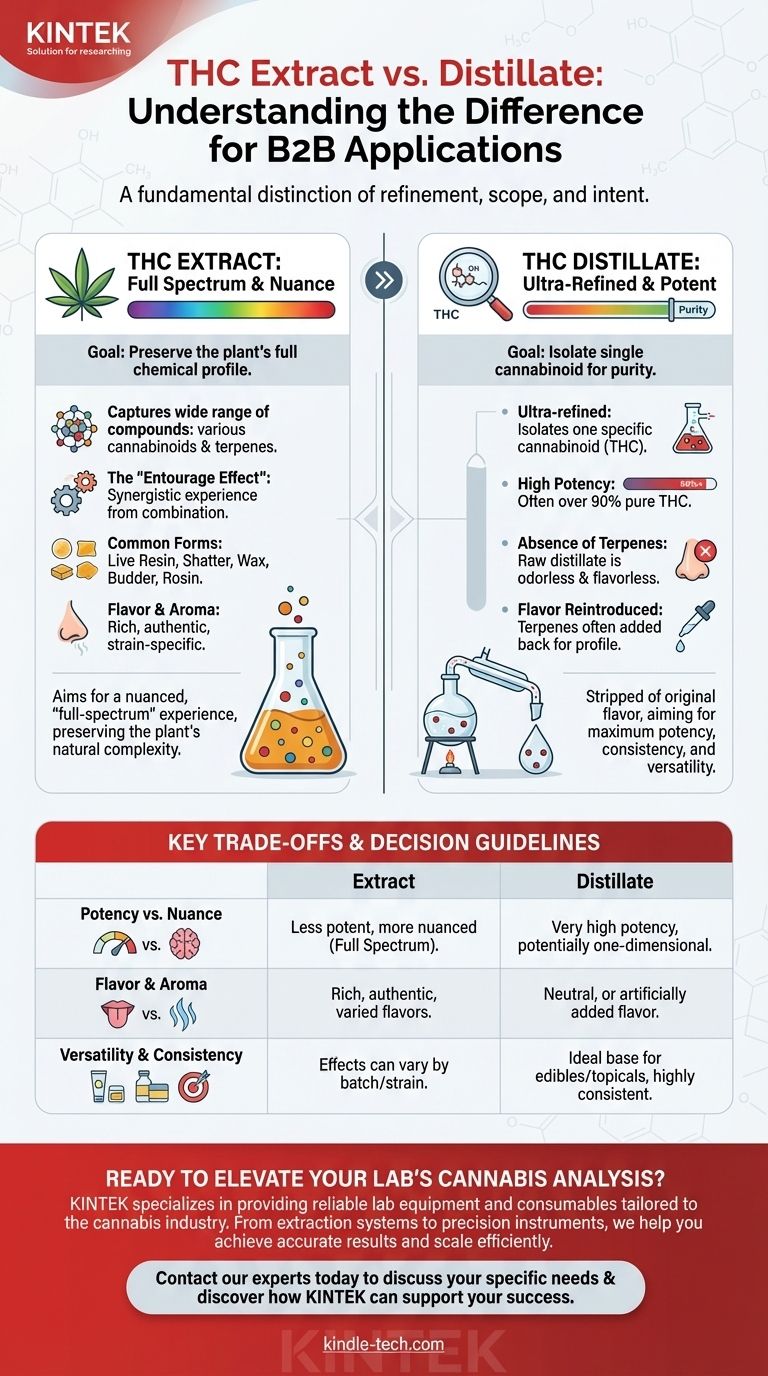

At a fundamental level, the difference is one of refinement and scope. A THC "extract" is a broad term for any concentrate that captures a wide range of the cannabis plant's compounds, including various cannabinoids and terpenes. A THC "distillate," in contrast, is an ultra-refined type of extract that has been purified to isolate a single cannabinoid—in this case, THC—resulting in a product with very high potency but without the plant's original flavor and aroma.

The core distinction lies in intent: extracts aim to preserve the plant's full chemical profile for a nuanced, "full-spectrum" experience, while distillates aim to isolate a single compound for maximum potency and versatility.

What Defines a Cannabis Extract?

An extract is the result of the first major step in separating the desirable parts of the cannabis plant from the raw plant matter. The goal is to concentrate the active ingredients.

The Goal: Capturing the Plant's Profile

The primary objective of most extraction processes is to create a concentrated version of the flower's natural chemical makeup. This includes not just THC but a host of other compounds.

A Broad Spectrum of Compounds

A quality extract contains a wide array of cannabinoids (like THC, CBD, CBG) and, crucially, terpenes. Terpenes are the aromatic compounds responsible for the distinct scent and flavor of different cannabis strains.

The "Entourage Effect" Principle

Many users and producers believe these compounds work together synergistically in what is known as the "entourage effect." The theory is that the combination of cannabinoids and terpenes creates a more complex and nuanced experience than any single compound could alone.

Common Forms of Extracts

The term "extract" is an umbrella category that includes products like live resin, shatter, wax, budder, and rosin. Each has a different consistency and is produced via methods (using solvents like CO2 or butane, or solventless methods) that aim to preserve the plant's original terpene profile.

What Defines Cannabis Distillate?

Distillate represents a further step in the refinement process. It takes a crude extract and purifies it to achieve an exceptionally high concentration of a single cannabinoid.

The Goal: Ultimate Purity and Potency

The sole objective of distillation is to isolate one specific cannabinoid, stripping away everything else. For THC distillate, this often results in a final product that is over 90% pure THC.

The Process of Refinement

Distillation uses heat and pressure to separate compounds based on their unique boiling points. In this process, cannabinoids like THC are separated from all other materials, including terpenes, lipids, and other plant matter.

The Absence of Natural Terpenes

The high heat used during distillation destroys the volatile terpenes. The resulting raw distillate is a thick, translucent oil that is completely odorless and flavorless.

Reintroducing Terpenes

Because raw distillate lacks flavor, manufacturers often add terpenes back into the product before it's sold. These can be cannabis-derived terpenes (from the original or other strains) or botanical terpenes (from other plants) to create a specific flavor profile.

Understanding the Key Trade-offs

Choosing between these products involves a clear set of trade-offs. There is no universally "better" option; the ideal choice depends entirely on your goal.

Potency vs. Nuance

Distillate offers the highest potency of a single cannabinoid (THC), leading to a very strong but potentially one-dimensional effect. Extracts offer a less potent but more nuanced and complex experience due to the full spectrum of compounds working together.

Flavor and Aroma

This is the most significant difference. Full-spectrum extracts provide the authentic, rich, and varied flavors of the original cannabis strain. Distillate is either flavorless or has a flavor that was added back in, which may not replicate the natural complexity of the plant.

Versatility

Distillate's neutral flavor makes it extremely versatile. It is the ideal base for edibles, beverages, and topicals because it adds potency without interfering with the product's taste.

Consistency

Distillate provides a highly consistent and predictable effect, making it easy to dose accurately. The effects of extracts can vary more significantly from batch to batch and strain to strain, reflecting the natural variations of the plant.

Making the Right Choice for Your Goal

Your ideal product depends entirely on the experience you are seeking. Use these guidelines to make a clear decision.

- If your primary focus is a rich, authentic flavor and the full "entourage effect": Choose a full-spectrum extract like live resin or rosin.

- If your primary focus is maximum THC potency and a highly consistent effect: Choose a THC distillate, especially for vape cartridges.

- If your primary focus is making discreet, precisely dosed edibles or topicals: Choose a distillate for its neutral profile and easy-to-measure potency.

- If your primary focus is experiencing the unique, nuanced character of a specific cannabis strain: Choose a well-made extract that has preserved the original terpene profile.

Understanding this distinction empowers you to select a product based not just on potency, but on the precise experience you want to achieve.

Summary Table:

| Feature | THC Extract | THC Distillate |

|---|---|---|

| Primary Goal | Preserve full plant profile (cannabinoids & terpenes) | Isolate THC for maximum purity and potency |

| THC Potency | Varies (typically lower) | Very high (often >90%) |

| Flavor/Aroma | Rich, natural, strain-specific | Neutral (flavorless) or artificially added |

| Key Compounds | Full-spectrum: THC, CBD, terpenes, etc. | Primarily isolated THC |

| Common Uses | Dabbing, vaping for flavor enthusiasts | Edibles, vapes, topicals for precise dosing |

| Experience | Nuanced "entourage effect" | Consistent, potent, one-dimensional |

Ready to Elevate Your Lab's Cannabis Analysis?

Whether you're developing full-spectrum extracts or high-purity distillates, having the right lab equipment is crucial for quality control and consistency. KINTEK specializes in providing reliable lab equipment and consumables tailored to the cannabis industry. From extraction systems to precision instruments, we help you achieve accurate results and scale your operations efficiently.

Contact our experts today to discuss your specific needs and discover how KINTEK can support your success in the growing cannabis market.

Visual Guide

Related Products

- Wall Mounted Water Distillation Unit

- Evaporation Crucible for Organic Matter

- Custom PTFE Teflon Parts Manufacturer for PTFE Bottle Oil Fume Sampling Tube

People Also Ask

- How is a crucible used in the crucible? Unpacking Arthur Miller's Powerful Metaphor

- How does biochar affect crop yield? A Guide to Maximizing Soil Health and Long-Term Productivity

- How can you control temperature inside a resistance furnace? Master Precise Thermal Management

- What are the disadvantages of pressing and sintering? Understand the Trade-offs in Powder Metallurgy

- What is the primary purpose of a condenser in EODS experiments? Prevent Volatilization and Ensure Data Accuracy

- What is the capacity of a plate and frame filter press? Understand the real-world throughput for your slurry.

- What is the temperature involved in the brazing process? Master the 4 Critical Phases for Perfect Joints

- What are the feedstocks for biochar production? Choose the Right Material for Your Application