In short, stainless steel reactors are primarily constructed from two specific grades: Type 304 and, more commonly for demanding applications, Type 316L. While both are "stainless steel," their subtle differences in composition lead to significant variations in performance, particularly in their ability to resist chemical attack. The choice between them is a critical engineering decision driven by the specific chemistry of your process.

The decision is not about which grade is universally "better," but which provides the necessary corrosion resistance for your specific application. Selecting the wrong material can lead to equipment failure, product contamination, and significant financial loss.

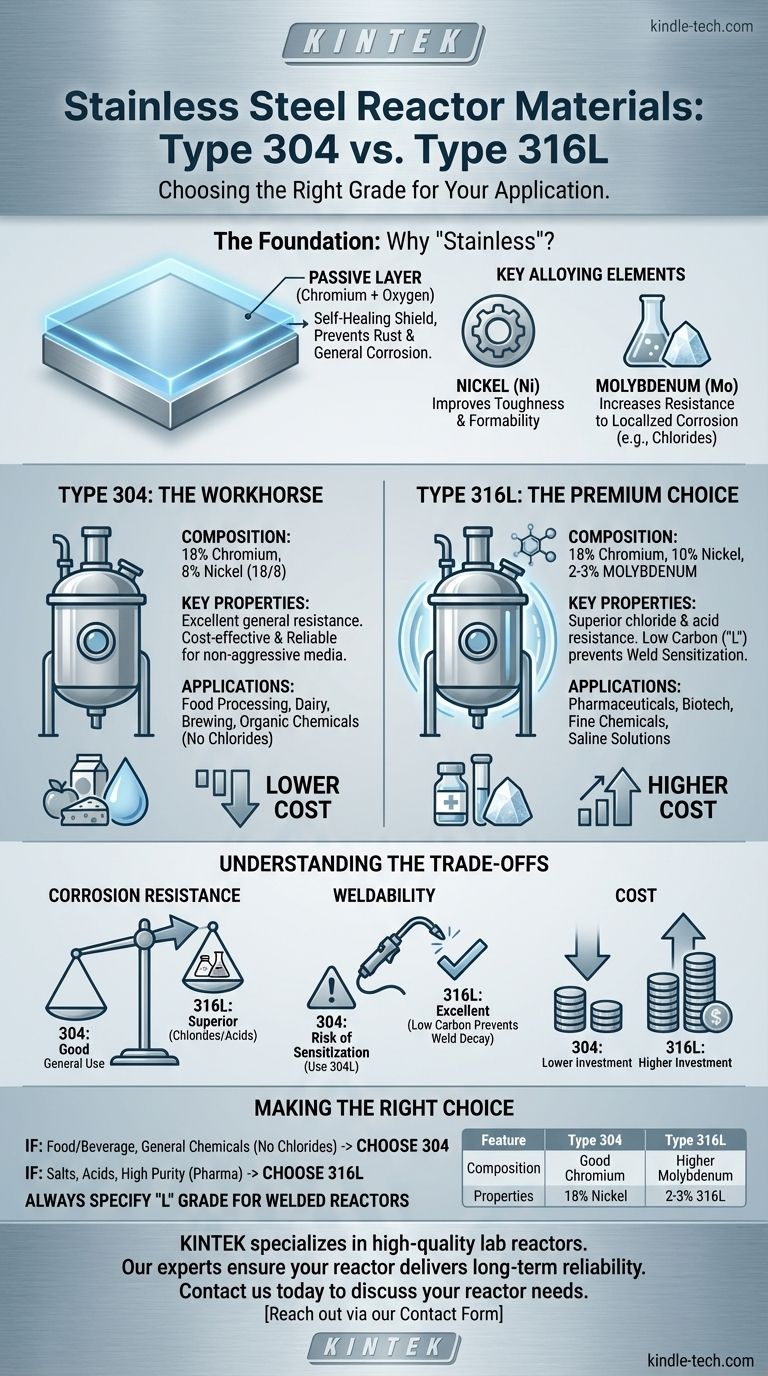

The Foundation: Why "Stainless" Steel?

Before comparing specific grades, it's crucial to understand what makes stainless steel resistant to corrosion. This knowledge forms the basis for selecting the right material for your reactor.

The Role of the Passive Layer

All stainless steels contain a minimum of 10.5% chromium. When exposed to oxygen, this chromium forms a thin, invisible, and incredibly durable film on the steel's surface called the passive layer.

This layer acts as a protective shield, instantly reforming itself if scratched or damaged. It's this self-healing shield that prevents rust and resists general corrosion.

Key Alloying Elements

Beyond iron and chromium, other elements are added to enhance specific properties. The two most important for reactors are:

- Nickel (Ni): Improves overall corrosion resistance, toughness, and formability.

- Molybdenum (Mo): Drastically increases resistance to localized corrosion, especially from chlorides (like salts and hydrochloric acid).

The Workhorse: Type 304 Stainless Steel

Type 304 is the most common stainless steel in the world. It is often referred to as "18/8" for its typical composition of 18% chromium and 8% nickel.

Key Properties and Applications

304 offers excellent resistance to a wide range of atmospheric and chemical agents. It is the standard choice for applications where corrosion is a general concern but not exceptionally aggressive.

You will find 304 stainless steel used widely in food processing, dairy, brewing, and for handling organic chemicals and water that are free of chlorides.

When 304 is the Right Choice

If your process involves materials that are not high in salts or acidic compounds, Type 304 is often the most cost-effective and reliable solution. It provides the necessary hygiene and general durability for many standard industrial applications.

The Premium Choice: Type 316L Stainless Steel

Type 316L is the preferred material for pharmaceutical, biotech, and fine chemical reactors. Its superior performance is due to one key addition and one important modification.

The Molybdenum Difference

Type 316 contains the same chromium and nickel as 304 but adds 2-3% molybdenum. This single change dramatically enhances its resistance to pitting and crevice corrosion caused by chlorides.

If your process involves saline solutions, seawater, or acidic chlorides, molybdenum is not optional; it is essential for the reactor's long-term survival.

The Importance of "L" Grade

The "L" in 316L stands for low carbon (typically below 0.03%). During welding, the high heat can cause carbon to combine with chromium, depleting the chromium needed for the passive layer at the weld seams. This phenomenon, called sensitization, creates a high risk for intergranular corrosion and weld failure.

Since reactors are fabricated with extensive welding, the low-carbon "L" grade is specified to prevent sensitization, ensuring the weld joints are as corrosion-resistant as the base metal.

Understanding the Trade-offs: 304 vs. 316L

Your choice will always be a balance between chemical compatibility, safety, and budget.

Corrosion Resistance

This is the primary differentiator. 316L's molybdenum content makes it vastly superior to 304 in any environment containing chlorides. Using 304 in a chloride-rich process is a predictable path to premature failure.

Weldability

For a heavily welded vessel like a reactor, 316L is the safer choice due to its low carbon content, which prevents weld decay (sensitization). While 304L also exists, 316L is the standard for high-purity and aggressive chemical applications where weld integrity is paramount.

Cost

There is a significant cost difference between the two grades. The addition of molybdenum and a higher percentage of nickel makes 316L notably more expensive than 304. This is why 304 is used where possible, and 316L is reserved for when it is technically necessary.

Making the Right Choice for Your Process

Base your material selection on a careful analysis of your process chemistry, operating temperatures, and purity requirements.

- If your primary focus is food/beverage or general chemicals without chlorides: Choose Type 304 for a proven, cost-effective, and reliable reactor.

- If your process involves salts, acids, or requires high purity (e.g., pharmaceuticals): Invest in Type 316L to ensure long-term corrosion resistance and prevent product contamination.

- If you are fabricating any new reactor: Always specify the "L" grade (304L or 316L) to guarantee the integrity of the welded seams against corrosion.

Ultimately, a thorough review of your chemical compatibility requirements is the only way to correctly specify a reactor that is both safe and economically sound.

Summary Table:

| Feature | Type 304 Stainless Steel | Type 316L Stainless Steel |

|---|---|---|

| Primary Alloying Elements | 18% Chromium, 8% Nickel | 18% Chromium, 10% Nickel, 2-3% Molybdenum |

| Key Advantage | Cost-effective for general use | Superior chloride & acid resistance |

| Best For | Food processing, organic chemicals, water (no chlorides) | Pharmaceuticals, fine chemicals, saline solutions |

| Weldability | Good (use 304L for welding) | Excellent (low carbon prevents sensitization) |

| Relative Cost | Lower | Higher |

Selecting the right reactor material is critical for your process safety and product purity. KINTEK specializes in high-quality lab reactors and equipment, helping you choose the perfect stainless steel grade (304 or 316L) for your specific chemical application. Our experts ensure your reactor delivers long-term reliability and prevents costly contamination. Contact us today to discuss your reactor needs and get a solution tailored to your lab's requirements. Reach out via our Contact Form

Visual Guide

Related Products

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Battery Lab Equipment 304 Stainless Steel Strip Foil 20um Thick for Battery Test

People Also Ask

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation

- What role does a high-temperature and high-pressure reactor play in CoFe2O4/Fe synthesis? Unlock Core-Shell Precision

- How does a high-pressure hydrothermal reactor facilitate the synthesis of mesoporous hydroxyapatite catalysts?

- Why are sealed laboratory reaction vessels necessary in the hydrothermal synthesis of zeolites? Ensure Purity and Yield

- What is the purpose of using a high-temperature hydrothermal reactor? Enhance Iodine@Activated Carbon Cathode Synthesis