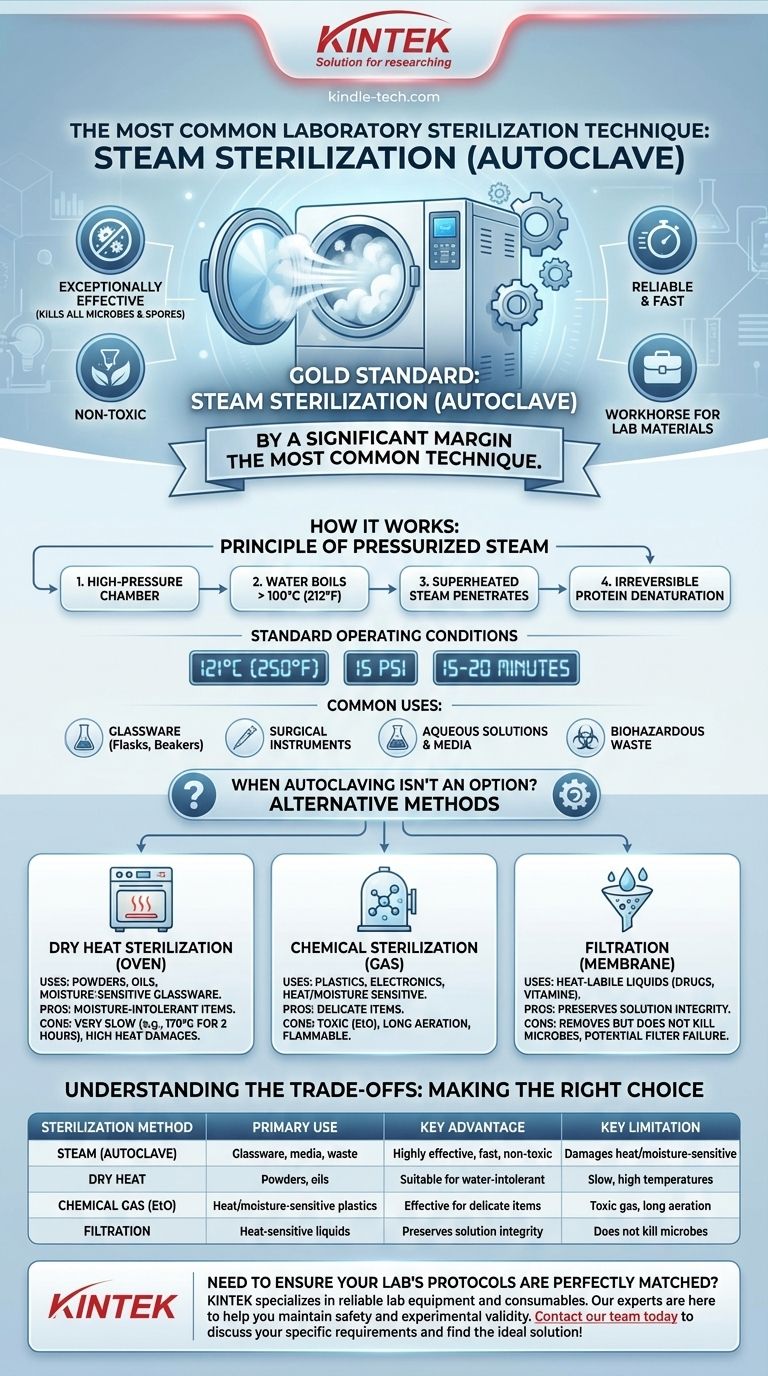

By a significant margin, the most common sterilization technique used in laboratories is steam sterilization, performed using a machine called an autoclave. This method is favored for its exceptional effectiveness at killing all forms of microbial life—including resilient bacterial spores—as well as its reliability, speed, and non-toxic nature. It has become the gold standard for sterilizing the majority of common lab materials.

While the autoclave is the undisputed workhorse for lab sterilization, the critical decision is not what's most common, but what is most appropriate. The choice of method must always be matched to the material's tolerance for heat, pressure, and moisture.

How Steam Sterilization Works: The Autoclave

The autoclave is essentially a sophisticated pressure cooker. It doesn't just use heat; it uses high-pressure, saturated steam to sterilize items.

The Principle of Pressurized Steam

The key to the autoclave's effectiveness is its ability to create an environment where water boils at a temperature higher than 100°C (212°F). Under pressure, this superheated steam can rapidly penetrate materials and transfer lethal heat.

This process irreversibly denatures the essential proteins and enzymes within microorganisms, ensuring their destruction.

Standard Operating Conditions

The most common cycle for laboratory autoclaving is running the chamber at 121°C (250°F) under a pressure of 15 pounds per square inch (psi) for at least 15-20 minutes.

The exact time can vary depending on the size and density of the load being sterilized.

What It's Used For

The autoclave is the go-to method for a wide range of common laboratory items.

This includes glassware (flasks, beakers, test tubes), surgical instruments, stainless steel equipment, aqueous solutions and culture media, and the decontamination of biohazardous waste.

When Autoclaving Isn't an Option: Other Methods

For materials that cannot withstand the high heat and moisture of an autoclave, laboratories rely on a few other key techniques.

Dry Heat Sterilization

This method uses an oven to sterilize items with hot, dry air. Because dry heat is less efficient at transferring energy than steam, it requires much higher temperatures and longer exposure times (e.g., 170°C for 2 hours).

It is primarily used for materials that are damaged by moisture, such as certain powders, oils, and types of glassware.

Chemical Sterilization

For items that are sensitive to both heat and moisture, such as plastics, fiber optics, and delicate electronics, chemical sterilization is used.

This often involves exposure to a toxic gas like ethylene oxide (EtO) within a specialized chamber. While effective, it requires a long aeration period afterward to remove harmful residual gas.

Filtration

This technique is used to sterilize heat-labile liquids, such as certain drug solutions, vitamins, or protein-based media supplements.

The liquid is passed through a filter with pores small enough (typically 0.22 micrometers) to trap and remove bacteria. It's important to note that filtration removes microbes but does not kill them, and it may not remove all viruses or endotoxins.

Understanding the Trade-offs

No single method is perfect for all applications. Understanding the pros and cons is fundamental to proper lab procedure.

Autoclave (Steam)

- Pros: Extremely effective, fast, non-toxic, and inexpensive to operate.

- Cons: Can damage heat-sensitive materials (like most plastics) and moisture-sensitive items. Can corrode certain metals.

Dry Heat

- Pros: Effective for moisture-sensitive materials like powders and oils.

- Cons: Very slow process. High temperatures can damage many items, and it is less efficient than steam.

Chemical Gas (Ethylene Oxide)

- Pros: Excellent for sterilizing heat- and moisture-sensitive items.

- Cons: The gas is highly toxic and flammable, requiring strict safety protocols and lengthy aeration times to ensure user safety.

Filtration

- Pros: The only effective method for sterilizing heat-sensitive liquids without destroying them.

- Cons: Does not remove all viruses, and the filter itself can be a point of failure if it ruptures or is not properly seated.

Making the Right Choice for Your Material

Your choice of sterilization method is dictated entirely by the object you need to sterilize.

- If your primary focus is glassware, media, or biohazardous waste: The autoclave is your most reliable and efficient choice.

- If your primary focus is heat-sensitive plastics or complex instruments: Chemical gas sterilization is likely the required method.

- If your primary focus is heat-sensitive liquids like serum or antibiotics: You must use sterile filtration to preserve the solution's integrity.

- If your primary focus is water-intolerant powders or oils: Dry heat sterilization is the appropriate technique.

Selecting the correct sterilization protocol is a foundational pillar of laboratory safety and experimental validity.

Summary Table:

| Sterilization Method | Primary Use | Key Advantage | Key Limitation |

|---|---|---|---|

| Steam (Autoclave) | Glassware, media, biohazard waste | Highly effective, fast, non-toxic | Damages heat/moisture-sensitive materials |

| Dry Heat | Powders, oils, moisture-sensitive items | Suitable for water-intolerant items | Slow process, high temperatures required |

| Chemical Gas (e.g., EtO) | Heat/moisture-sensitive plastics, instruments | Effective for delicate items | Toxic gas, requires lengthy aeration |

| Filtration | Heat-sensitive liquids (serum, antibiotics) | Preserves solution integrity | Does not kill microbes, only removes them |

Need to ensure your lab's sterilization protocols are perfectly matched to your equipment and materials?

KINTEK specializes in providing reliable lab equipment and consumables to meet all your sterilization needs. Whether you require a robust autoclave for everyday use or guidance on the best method for sensitive materials, our experts are here to help you maintain the highest standards of safety and experimental validity.

Contact our team today to discuss your specific laboratory requirements and find the ideal solution!

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

People Also Ask

- How does an autoclave sterilize instruments supplies and equipment? A Guide to High-Pressure Steam Sterilization

- What are the settings for autoclave sterilization? Ensure Reliable Sterility with Proper Parameters

- How much time is required for autoclave sterilization of instruments? Understand the Full Cycle for Safety

- What precautions should be taken during autoclave in laboratory? A Complete Safety Guide to Prevent Burns and Explosions

- Why is proper maintenance and cleaning of the autoclave important? Ensure Sterilization Efficacy and Safety