The most effective method for sterilizing laboratory materials is steam sterilization, a thermal process commonly known as autoclaving. For the vast majority of lab applications—including glassware, metal instruments, and microbiological media—its ability to use pressurized steam to kill all forms of microbial life, including resilient spores, makes it the unrivaled standard for reliability, speed, and safety.

The concept of a single "most effective" sterilization method is a misconception. The ideal method is dictated entirely by the material's composition. While steam autoclaving is the default for heat-stable items, choosing the right alternative for sensitive materials is critical for experimental success and safety.

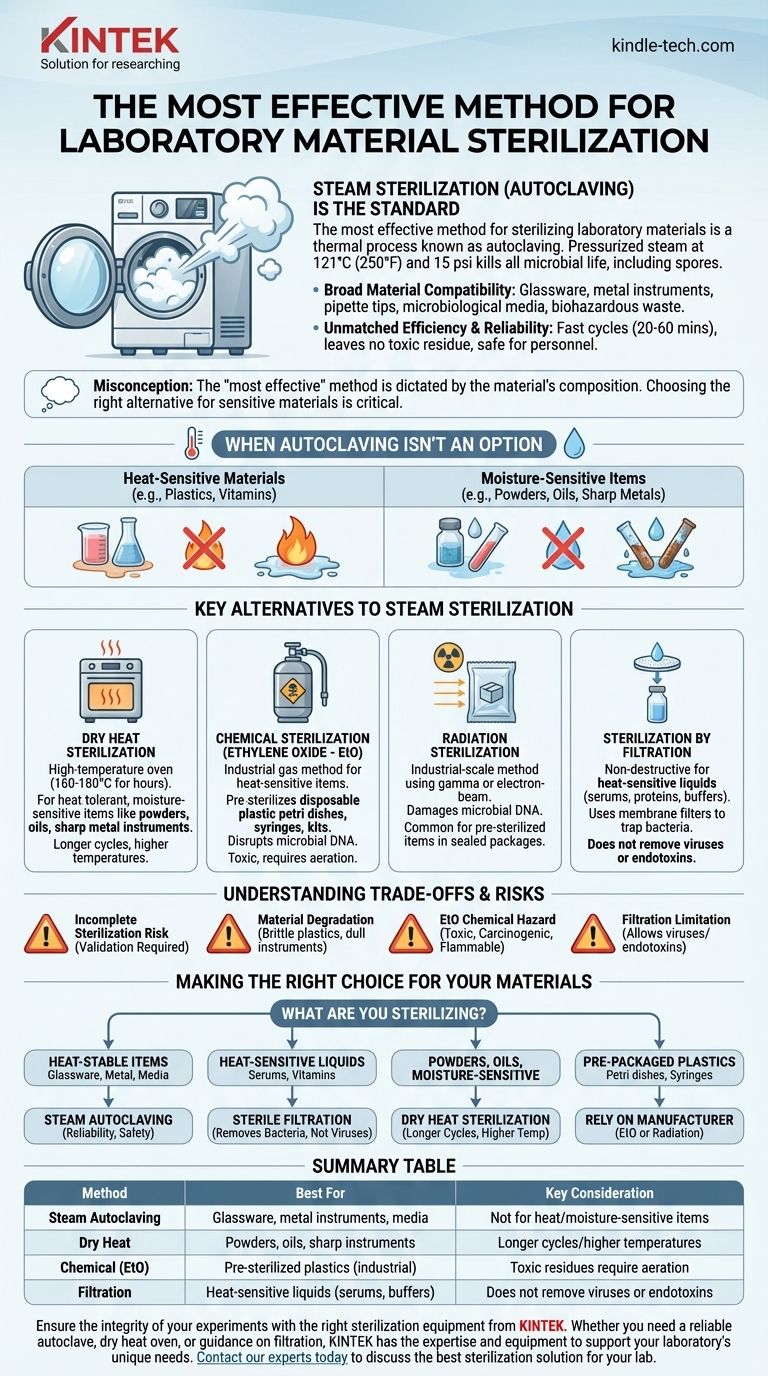

Why Steam Sterilization (Autoclaving) is the Standard

Steam sterilization is the workhorse of most biological and chemical laboratories for several compelling reasons. It is a physical process that leaves behind no toxic residue, making it safe for both personnel and subsequent experiments.

The Principle of Pressurized Steam

An autoclave does not sterilize with dry heat; it uses high-pressure steam. At a typical setting of 121°C (250°F) and 15 psi, the moist heat rapidly denatures the essential proteins and enzymes within microorganisms, leading to their death. This process is far more efficient at heat transfer than dry air, allowing for shorter sterilization cycles.

Broad Material Compatibility

This method is the first choice for a wide range of common laboratory items. This includes all autoclavable glassware (beakers, flasks, bottles), stainless steel instruments, pipette tips, microbiological media and buffers, and biohazardous waste.

Unmatched Efficiency and Reliability

Compared to other methods, autoclaving is fast, with typical cycles running from 20 to 60 minutes depending on the load. The process is highly reliable and easily validated with biological or chemical indicators to ensure every cycle achieves complete sterility.

When Autoclaving Isn't an Option

The primary limitation of an autoclave is its reliance on high heat and moisture. Attempting to autoclave an incompatible item will not only fail to sterilize it but will likely destroy the material and potentially damage the equipment.

Handling Heat-Sensitive Materials

Many essential laboratory materials cannot withstand the high temperatures of an autoclave. This includes most plastics (like petri dishes and some centrifuge tubes), heat-labile chemical solutions, vitamins, antibiotics, and items containing electronic components.

Handling Moisture-Sensitive Items

Certain materials are incompatible with steam because they are either degraded by moisture or must remain perfectly dry. This includes powders, oils, and certain metal instruments that are susceptible to corrosion.

Key Alternatives to Steam Sterilization

When autoclaving is not suitable, several other established methods are used, each serving a specific purpose. These are often employed on an industrial scale for producing the pre-sterilized disposables used in the lab.

Dry Heat Sterilization

This thermal process uses a high-temperature oven, typically operating between 160-180°C for several hours. Because dry heat is less efficient at killing microbes, it requires much longer exposure times and higher temperatures. It is primarily used for materials that can tolerate heat but not moisture, such as powders, oils, and sharp metal instruments.

Chemical Sterilization (Ethylene Oxide - EtO)

For heat-sensitive items, gas sterilization with ethylene oxide (EtO) is a common industrial method. EtO is a potent alkylating agent that disrupts microbial DNA. It is used to pre-sterilize a huge range of disposable labware, including plastic petri dishes, syringes, catheters, and packaged kits.

Radiation Sterilization

Gamma or electron-beam radiation is another industrial-scale method for sterilizing heat-sensitive disposables. High-energy radiation damages microbial DNA beyond repair. If your gloves, swabs, or syringes arrive in a sealed package marked "sterile," they were likely sterilized with this method or EtO.

Sterilization by Filtration

Filtration is a non-destructive method used exclusively for heat-sensitive liquids, such as cell culture media containing serum, protein solutions, or vitamin supplements. The liquid is passed through a membrane filter with a pore size (typically 0.22 µm) small enough to trap and remove bacteria.

Understanding the Trade-offs and Risks

Every sterilization method has inherent limitations and requires proper execution to be effective. Misunderstanding these trade-offs can compromise your results.

The Risk of Incomplete Sterilization

The most significant risk is failure to achieve sterility. This can be caused by overloading an autoclave, using an incorrect cycle time, failing to allow for steam penetration, or using a filter that is not intact. Validation is not optional; it is a required step to confirm your process works.

Material Degradation

Even for compatible materials, repeated sterilization can cause degradation. Autoclaving can cause certain plastics (like polypropylene) to become brittle over time. Dry heat can char organic materials and will dull sharp instruments more quickly than steam.

The Chemical Hazard of Ethylene Oxide

EtO is highly effective but also toxic, carcinogenic, and flammable. Items sterilized with EtO must undergo a lengthy aeration process to remove residual gas, making it unsuitable for in-lab, on-demand use. It is almost exclusively an industrial process.

Filtration's Key Limitation

While filtration effectively removes bacteria and fungi, it does not remove smaller viruses or endotoxins (toxic components of bacterial cell walls). For applications like cell culture or injectables, this can be a critical point of failure.

Making the Right Choice for Your Materials

Choosing your sterilization method is a foundational decision that impacts the validity of your work. Base your choice on the nature of the material you need to sterilize.

- If your primary focus is heat-stable items (glassware, metal, most media): Default to steam sterilization (autoclaving) for its unmatched reliability and safety.

- If your primary focus is heat-sensitive liquids (serums, vitamins, protein solutions): Use sterile filtration to remove bacteria without denaturing your critical components.

- If your primary focus is powders, oils, or moisture-sensitive instruments: Choose dry heat sterilization, but validate the significantly longer cycle times required.

- If your primary focus is using pre-packaged plastics (petri dishes, syringes): Rely on the manufacturer's sterilization, which is typically performed with ethylene oxide or radiation.

Selecting the correct sterilization method is fundamental to ensuring the integrity and validity of your laboratory work.

Summary Table:

| Method | Best For | Key Consideration |

|---|---|---|

| Steam Autoclaving | Glassware, metal instruments, media | Not suitable for heat/moisture-sensitive items |

| Dry Heat | Powders, oils, sharp instruments | Requires longer cycles/higher temperatures |

| Chemical (EtO) | Pre-sterilized plastics (industrial) | Toxic residues require aeration |

| Filtration | Heat-sensitive liquids (serums, buffers) | Does not remove viruses or endotoxins |

Ensure the integrity of your experiments with the right sterilization equipment from KINTEK.

Choosing the correct sterilization method is critical for laboratory safety and success. Whether you need a reliable autoclave for your daily glassware, a dry heat oven for moisture-sensitive instruments, or guidance on handling heat-sensitive liquids, KINTEK has the expertise and equipment to support your laboratory's unique needs.

We specialize in providing high-quality lab equipment and consumables, ensuring your sterilization processes are effective, validated, and efficient.

Contact our experts today to discuss the best sterilization solution for your lab.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

People Also Ask

- What is the difference between UV sterilizer and autoclave? Sterilization vs. Disinfection Explained

- How is an autoclave utilized in antimicrobial experiments? Ensure Precise Nanoparticle Research Integrity

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment

- What is the temperature above 100 for autoclaving? Achieve Sterilization at 121°C

- What is the primary purpose of mini-autoclaves in supercritical water corrosion? Ensure Data Integrity with KINTEK

- Why is a high-pressure steam autoclave necessary for dilute acid pretreatment? Unlock Biomass Potential at 120°C

- Why is a pressure steam sterilizer necessary for laboratory equipment? Ensure Accuracy in Disinfection Research

- What does the autoclaving process involve? Master the 3 Phases for Reliable Sterilization