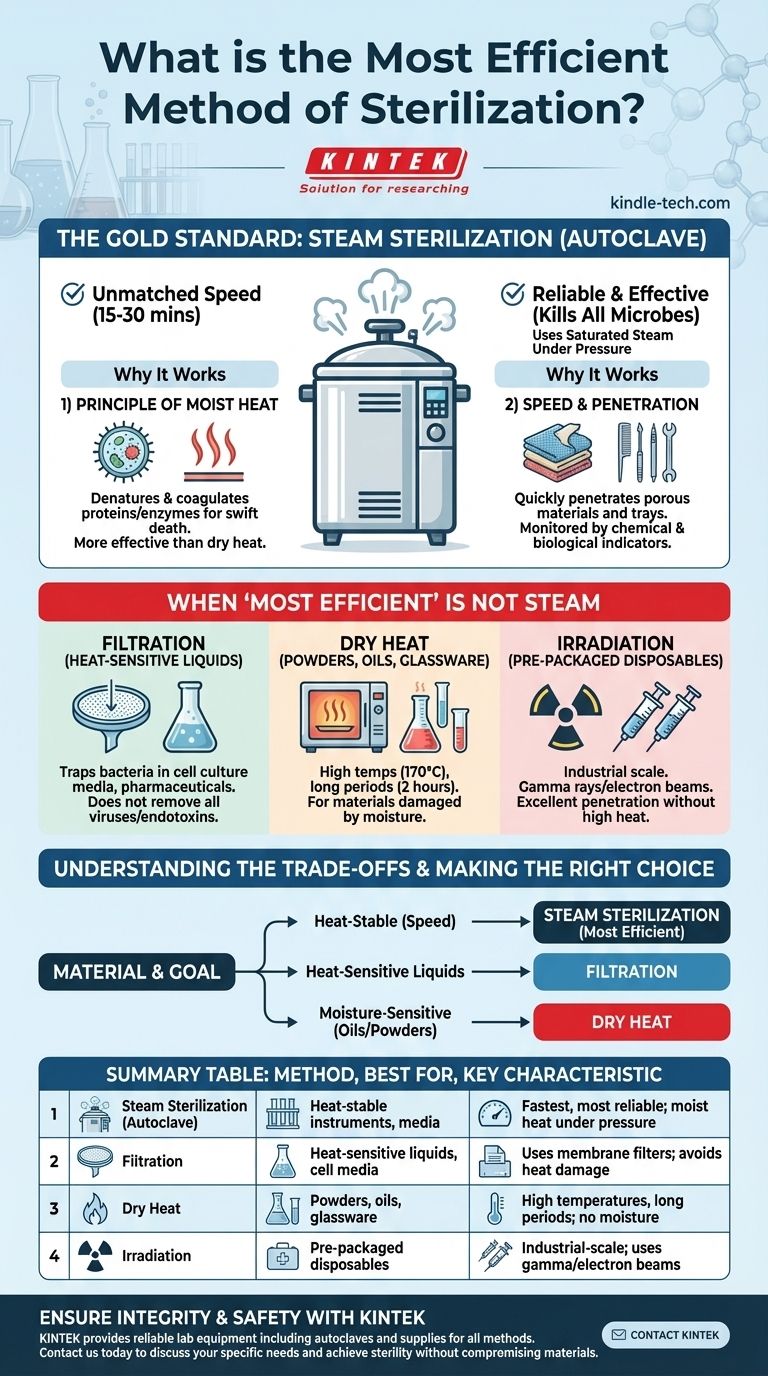

By far, the most efficient and widely used method of sterilization is steam sterilization. More specifically, this is achieved using saturated steam under pressure in a device called an autoclave. This method is considered the gold standard in healthcare and laboratory settings due to its unmatched speed, reliability, and effectiveness in killing all forms of microbial life, including resilient bacterial spores.

While steam sterilization is the undisputed champion for speed and dependability, true efficiency lies in matching the sterilization method to the material. The most "efficient" method is the one that reliably sterilizes an object without damaging it.

Why Steam Sterilization Is the Gold Standard

Steam sterilization, also known as autoclaving, is a process of heating with controlled temperature and time. Its dominance is not accidental; it is based on fundamental biophysical principles.

The Principle of Moist Heat

Moist heat is significantly more effective at killing microorganisms than dry heat. The pressurized steam rapidly transfers thermal energy, which denatures and coagulates essential proteins and enzymes within microbial cells, leading to their swift death.

This process is much faster than dry heat, which kills microbes primarily through a slower process of oxidation.

Unmatched Speed and Penetration

Steam under pressure can quickly penetrate fabrics, surgical instrument trays, and other porous materials. A typical autoclave cycle can achieve complete sterilization in as little as 15-30 minutes, depending on the load's size and density.

Reliability and Validation

The effectiveness of an autoclave cycle is easily monitored and validated. Chemical indicators change color to show proper temperature has been reached, while biological indicators containing heat-resistant spores are used to definitively prove that the process was lethal to the most robust microorganisms.

When "Most Efficient" Is Not Steam

The primary limitation of steam sterilization is its reliance on high heat and moisture. For many common materials, using an autoclave is not an option. This is where understanding alternative methods becomes critical.

For Heat-Sensitive Liquids

Filtration is the method of choice for sterilizing heat-sensitive solutions, such as cell culture media or pharmaceuticals. The liquid is passed through a membrane filter with a pore size small enough (typically 0.22 micrometers) to trap bacteria.

For Powders, Oils, and Glassware

Dry heat sterilization is used for materials that are damaged by moisture or cannot be penetrated by steam, such as anhydrous oils, powders, and empty glassware. This process requires much higher temperatures (e.g., 170°C) and significantly longer exposure times (e.g., 2 hours) compared to autoclaving.

For Pre-Packaged Disposables and Electronics

Irradiation, using gamma rays or electron beams, is the industrial standard for sterilizing vast quantities of pre-packaged items like syringes, sutures, and catheters. This method offers excellent penetration without high heat, but it requires highly specialized facilities.

Understanding the Trade-offs

No single sterilization method is perfect for every situation. Choosing the right one requires a clear understanding of their inherent limitations.

The Drawbacks of Steam

The primary disadvantage of steam is its incompatibility with many materials. It will melt many plastics, corrode certain metals, and destroy sensitive electronic instruments. It is also completely ineffective for sterilizing oils and powders.

The Limitations of Alternatives

Filtration does not remove all viruses or endotoxins, which can be a critical concern in some applications. Dry heat is slow and can damage some materials due to the prolonged exposure to high temperatures. Irradiation can degrade certain polymers and is not a feasible option outside of an industrial production environment.

Making the Right Choice for Your Application

Your choice of sterilization method must be guided by the material you are working with and your primary goal.

- If your primary focus is speed and reliability for heat-stable items: Steam sterilization (autoclaving) is the most efficient and dependable choice.

- If your primary focus is sterilizing heat-sensitive liquids or media: Filtration is the correct and most practical method.

- If your primary focus is sterilizing moisture-sensitive materials like oils or powders: Dry heat sterilization is the necessary approach, despite its slowness.

Ultimately, selecting the right sterilization method is a critical decision based on a simple principle: ensuring sterility without compromising the integrity of the item.

Summary Table:

| Method | Best For | Key Characteristic |

|---|---|---|

| Steam Sterilization (Autoclave) | Heat-stable instruments, media | Fastest, most reliable; uses moist heat under pressure |

| Filtration | Heat-sensitive liquids, cell media | Uses membrane filters; avoids heat damage |

| Dry Heat | Powders, oils, glassware | High temperatures for long periods; no moisture |

| Irradiation | Pre-packaged disposables | Industrial-scale; uses gamma or electron beams |

Ensure the integrity and safety of your laboratory work with the right sterilization equipment from KINTEK.

Choosing the correct sterilization method is critical for your research, diagnostics, and production processes. KINTEK specializes in providing reliable lab equipment and consumables, including autoclaves for steam sterilization and supplies for other methods. Our experts can help you select the perfect solution to achieve sterility without compromising your valuable materials.

Contact us today via our contact form to discuss your specific laboratory needs and let KINTEK be your partner in precision and safety.

Visual Guide

Related Products

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

- Desktop Fast High Pressure Laboratory Autoclave Sterilizer 16L 24L for Lab Use

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What role does a laboratory autoclave play in the separation of lignin? High-Purity Extraction for Biomass Research

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam

- What extreme conditions does a laboratory autoclave simulate? Testing Wear Resistance of Nuclear Fuel Cladding

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment