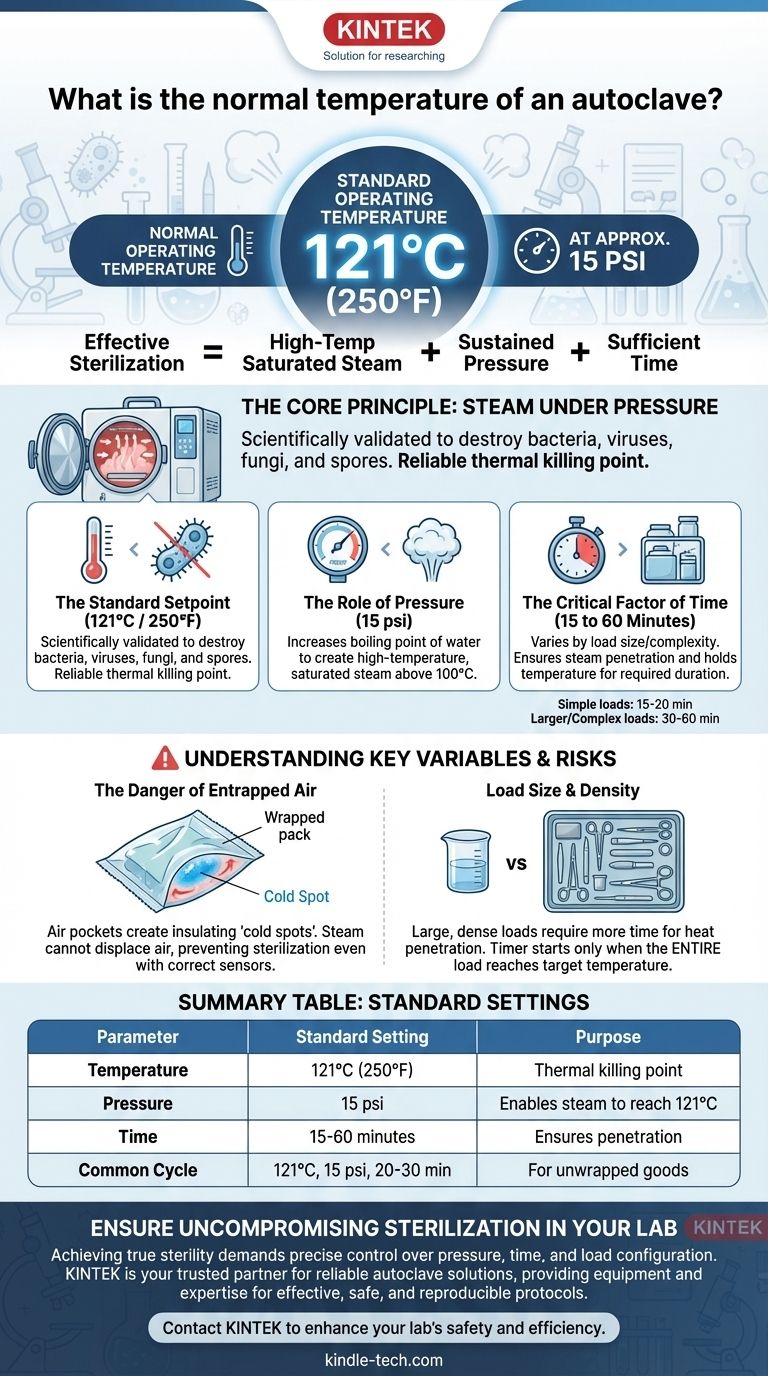

The standard operating temperature for most autoclave sterilization cycles is 121°C (250°F). This temperature is achieved by using saturated steam under a pressure of approximately 15 pounds per square inch (psi). Reaching this temperature is only one part of the equation; the duration of the cycle is equally critical for ensuring complete sterilization.

Effective sterilization is not defined by a single temperature. It is achieved through a precise relationship between three critical factors: high-temperature saturated steam, sustained pressure, and sufficient time. Altering one of these variables without adjusting the others can lead to a failed sterilization cycle.

The Core Principle: Steam Under Pressure

To understand why 121°C is the standard, you must first understand how an autoclave works. It’s not simply a hot oven; it’s a high-pressure vessel designed to kill microorganisms with penetrating, high-energy steam.

The Standard Setpoint: 121°C (250°F)

This temperature has been scientifically validated as effective for destroying a vast range of bacteria, viruses, fungi, and resilient bacterial spores. It provides a reliable thermal killing point for most laboratory and medical applications.

The Role of Pressure: 15 psi

At normal atmospheric pressure, water boils at 100°C (212°F). To reach the more effective sterilization temperature of 121°C, the autoclave increases the pressure inside its chamber to approximately 15 psi above atmospheric pressure. This pressure prevents the water from boiling away and allows the creation of high-temperature, saturated steam.

The Critical Factor of Time: 15 to 60 Minutes

The time required to sterilize a load can vary significantly. While a small load of simple instruments might be sterile after 15-20 minutes at 121°C, larger or more complex loads require longer.

Durations of 30 to 60 minutes are common for larger volumes, liquid media, or densely packed instruments to ensure the steam fully penetrates to the core of the load and holds it at 121°C for the required time.

Understanding the Key Variables and Risks

Setting the correct temperature is the first step, but several other factors determine whether a cycle will succeed or fail. Ignoring them is a common cause of sterilization failures.

The Danger of Entrapped Air

This is the most critical and often overlooked factor. If air is trapped within the load (e.g., in an improperly wrapped pack or an unvented bottle), it creates an insulating "cold spot." Steam cannot displace this air, so the items in that spot will never reach the target temperature, even if the autoclave's sensors report a successful cycle.

Load Size and Density

A large, dense load of surgical instruments requires significantly more time for heat to penetrate than a few glass beakers. The timer for sterilization only begins once the entire load reaches the target temperature, not just the chamber itself.

Liquid vs. Solid Cycles

Sterilizing liquids (like microbiological media) is different from sterilizing solid instruments. Liquids heat up and cool down much more slowly. They require specific "liquid cycles" with slow exhaust phases to prevent the superheated liquid from boiling over violently when the pressure is released.

How to Set Your Cycle for Reliable Sterility

Use these guidelines to determine the correct parameters for your specific application. When in doubt, always err on the side of a longer cycle time.

- If your primary focus is sterilizing simple, unwrapped hard goods (e.g., glassware, metal tools): A cycle of 121°C at 15 psi for 20-30 minutes is a reliable standard.

- If your primary focus is sterilizing liquids or waste bags: You must use a dedicated liquid or waste cycle with a longer duration (often 45-60 minutes) to ensure penetration and safe cooling.

- If your primary focus is sterilizing wrapped instrument packs or porous materials: You must ensure your autoclave has a pre-vacuum cycle to remove air effectively before steam is injected.

Mastering the interplay of temperature, pressure, and time is the key to achieving consistent and verifiable sterilization.

Summary Table:

| Parameter | Standard Setting | Purpose |

|---|---|---|

| Temperature | 121°C (250°F) | Thermal killing point for microorganisms |

| Pressure | 15 psi | Enables steam to reach 121°C |

| Time | 15-60 minutes | Ensures steam penetration and sterilization |

| Common Cycle | 121°C, 15 psi, 20-30 min | For unwrapped glassware and instruments |

Ensure Uncompromising Sterilization in Your Lab

Achieving true sterility requires more than just setting a temperature. It demands precise control over pressure, cycle time, and load configuration to eliminate risks like cold spots and incomplete penetration.

KINTEK is your trusted partner for reliable autoclave solutions. We provide the equipment and expertise to ensure your sterilization protocols are effective, safe, and reproducible. Whether you're processing liquids, wrapped packs, or solid instruments, our autoclaves are designed for consistent performance.

Let us help you enhance your lab's safety and efficiency. Contact KINTEK today to find the perfect autoclave for your specific laboratory needs.

Visual Guide

Related Products

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

People Also Ask

- What is the main purpose of the autoclave? Achieve Complete Sterilization with High-Pressure Steam

- Is a sterilizer an autoclave? Understand the Key Differences for Your Lab

- For what purpose are high-pressure autoclaves used in the synthesis of additives for composite polymer electrolytes?

- What are examples of autoclave in microbiology? Essential Sterilization for Lab Safety & Accuracy

- What is the most commonly used autoclave? Discover the Industry Standard for Sterilization

- What is the primary difference between pharmaceutical and waste autoclaves? Purity vs. Sterility Explained

- What is a laboratory autoclave? A Guide to Sterilization with Pressurized Steam

- Is autoclave the same as sterilization? Unlocking the Key Differences for Lab Safety