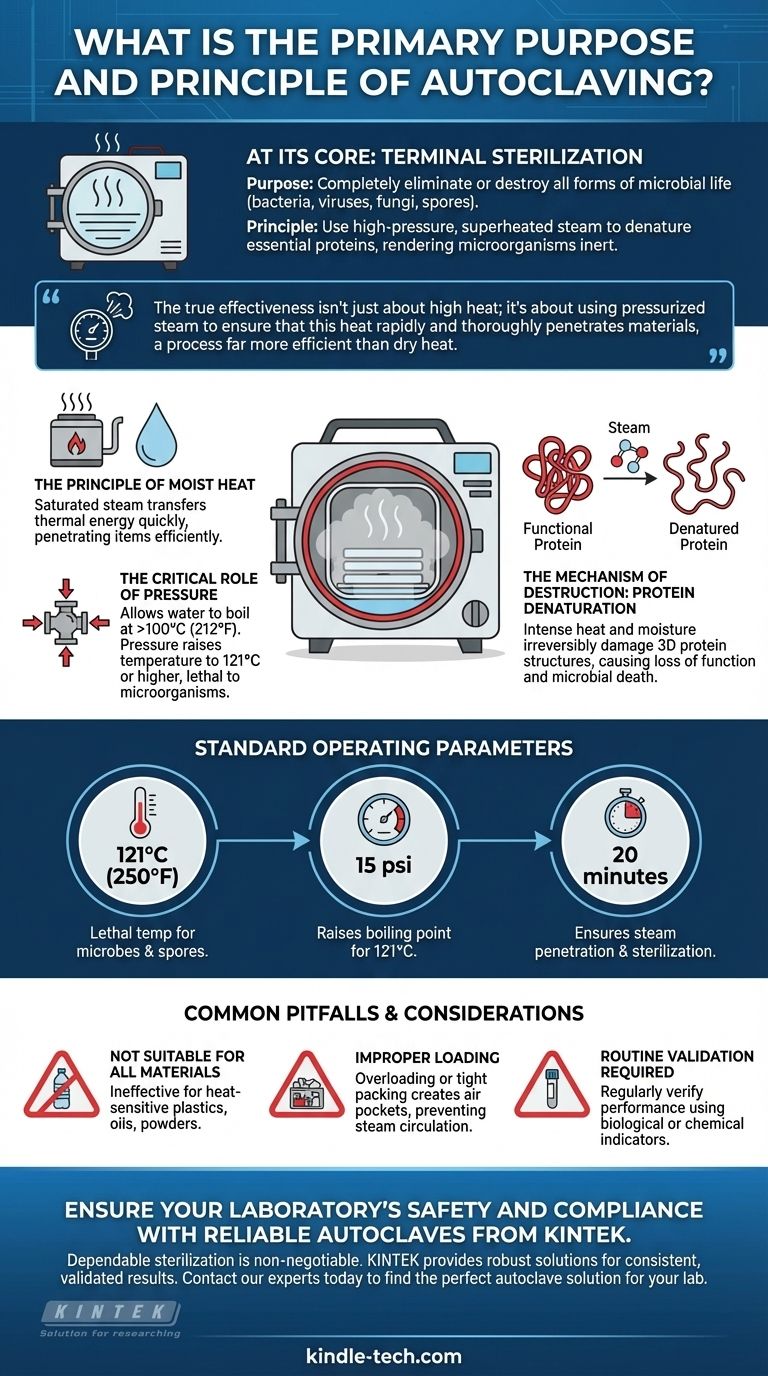

At its core, autoclaving is the most dependable method for terminal sterilization. Its primary purpose is to completely eliminate or destroy all forms of microbial life, including bacteria, viruses, fungi, and highly resistant bacterial spores. This is achieved through its core principle: using high-pressure, superheated steam to denature the essential proteins of these microorganisms, rendering them non-functional and inert.

The true effectiveness of an autoclave isn't just about high heat; it's about using pressurized steam to ensure that this heat rapidly and thoroughly penetrates materials, a process far more efficient than dry heat for achieving complete sterilization.

How an Autoclave Achieves Complete Sterilization

To understand why autoclaving is the gold standard in many fields, we need to look beyond the surface and examine the interplay of its core components: steam, pressure, and temperature.

The Principle of Moist Heat

Moist heat, in the form of saturated steam, is a significantly more effective agent for sterilization than dry heat.

Steam is able to transfer thermal energy much more efficiently than air, allowing it to quickly heat and penetrate contaminated items within the autoclave chamber.

The Critical Role of Pressure

The pressure inside an autoclave serves one primary, crucial function: it allows water to boil at a temperature much higher than its normal 100°C (212°F).

By increasing the pressure, the system can generate steam at temperatures of 121°C or higher. This elevated temperature is lethal to a wider range of microorganisms, especially heat-resistant spores.

The Mechanism of Destruction: Protein Denaturation

The combination of intense heat and moisture delivered by the steam attacks the essential proteins and enzymes within microorganisms.

This process, known as denaturation, irreversibly damages the three-dimensional structure of these proteins, causing them to lose their function. Without functional proteins, the microbes' cellular machinery collapses, leading to rapid death.

Standard Operating Parameters

While cycles can be adjusted, a universal standard has been established for most routine sterilization tasks, ensuring consistent and reliable results.

The 121°C / 15 psi Standard

The most common and widely recognized autoclave cycle operates at 121°C (250°F) under a pressure of 15 pounds per square inch (psi) above atmospheric pressure.

This specific combination of temperature and pressure is proven to be highly effective at destroying even the most resilient bacterial spores.

The Factor of Time

Temperature and pressure alone are not enough. The materials must be exposed for a sufficient duration to ensure the steam penetrates the entire load.

A typical cycle time is 20 minutes at 121°C, though this can be adjusted based on the size, density, and nature of the items being sterilized.

Common Pitfalls and Considerations

While highly effective, the success of autoclaving depends on proper use. Operator error or a misunderstanding of its limitations can lead to incomplete sterilization.

Not Suitable for All Materials

Autoclaving is an aggressive process. It is not suitable for heat-sensitive materials, such as certain plastics, that will melt or deform.

Furthermore, it is ineffective for sterilizing water-repellent substances like oils or powders, as the steam cannot penetrate these materials to deliver its lethal heat.

The Importance of Proper Loading

One of the most common causes of sterilization failure is improper loading of the autoclave chamber.

Overloading the machine or packing items too tightly can create air pockets that insulate microorganisms from the steam. Items must be arranged to allow for free circulation of steam to all surfaces.

Requirement for Routine Validation

Simply running a cycle does not guarantee sterilization. Facilities must regularly validate autoclave performance using biological or chemical indicators.

Biological indicators, which contain highly resistant spores, are the ultimate test. If the spores are killed during the cycle, it provides a high degree of confidence that the process was successful.

Making the Right Choice for Your Goal

Understanding these principles allows you to apply autoclaving effectively and safely, ensuring the integrity of your work.

- If your primary focus is sterilizing laboratory equipment: Ensure all items are properly cleaned beforehand and arranged within the chamber to maximize steam penetration, avoiding dense packing.

- If your primary focus is decontaminating biohazardous waste: Use validated autoclave bags with a steam indicator and ensure the cycle time is sufficient to penetrate the entire volume of the waste.

- If your primary focus is maintaining operational compliance: Implement a routine quality control schedule using biological indicators to verify that every cycle meets sterilization standards.

Mastering the principles of autoclaving transforms it from a simple machine into a cornerstone of safety and reliable scientific outcomes.

Summary Table:

| Parameter | Standard Value | Purpose |

|---|---|---|

| Temperature | 121°C (250°F) | Lethal temperature for microbes and spores. |

| Pressure | 15 psi | Raises water's boiling point to achieve 121°C. |

| Time | 20 minutes (typical) | Ensures steam penetration and complete sterilization. |

Ensure your laboratory's safety and compliance with reliable autoclaves from KINTEK.

As specialists in lab equipment, we understand that dependable sterilization is non-negotiable. Whether you are processing lab equipment, decontaminating biohazardous waste, or maintaining strict quality control protocols, the right autoclave is critical.

KINTEK provides robust solutions tailored to your laboratory's specific needs, helping you achieve consistent, validated results.

Contact our experts today to find the perfect autoclave solution for your lab.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- What is the life expectancy of an autoclave machine? Maximize Your Investment with Proper Care

- What types of items and materials can be processed in a laboratory autoclave? Essential Guide for Lab Safety

- Why is the standard autoclave temperature set to 121? The Science of Effective Sterilization

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam