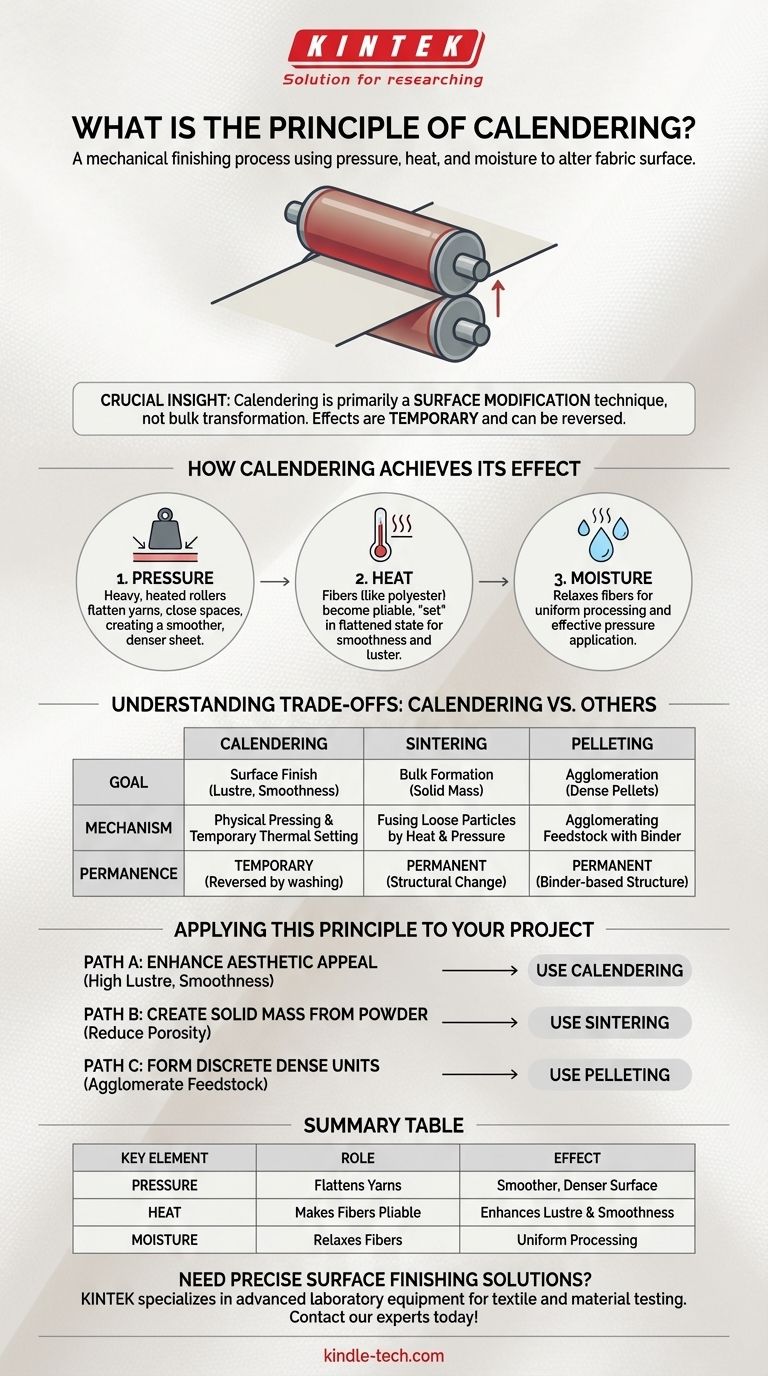

At its core, calendering is a mechanical finishing process that uses the combined effect of intense pressure, heat, and moisture to alter the surface of a fabric. By passing cloth between large, heavy rollers (known as calenders), the process flattens the yarns and fibers, creating a much smoother, denser, and more light-reflective surface that appears lustrous.

The crucial insight is that calendering is primarily a surface modification technique, not a bulk material transformation. Its effects—smoothness and lustre—are typically temporary and can be reversed by washing, as the process physically reshapes fibers rather than chemically bonding them.

How Calendering Achieves Its Effect

The final result of calendering is born from the precise interaction of three key elements: pressure, heat, and moisture. Each plays a distinct role in temporarily reconfiguring the fabric's structure.

The Role of Pressure

Heavy, heated rollers exert immense pressure on the fabric as it passes through the nip, or the point of contact.

This force physically flattens the yarns and closes the interstitial spaces within the fabric weave. The result is a thinner, more compact, and smoother sheet.

The Role of Heat

Heat makes the textile's fibers—particularly thermoplastic ones like polyester—more pliable and susceptible to deformation.

The temperature allows the fibers to be "set" into their new, flattened configuration. This thermal setting is key to achieving the desired smoothness and lustre, similar to how an iron sets the press on a shirt.

The Role of Moisture

Moisture, often applied as steam, helps to relax the fibers and make them more receptive to the calendering process.

A conditioned fabric allows for more uniform heat transfer and plasticization, ensuring the pressure is applied effectively across the entire surface.

Understanding the Trade-offs: Calendering vs. Other Processes

While calendering uses heat and pressure, its principle and goal are fundamentally different from other industrial processes like sintering or pelleting. Confusing them can lead to misapplication.

The Goal: Surface Finish vs. Bulk Formation

Calendering is a finishing process applied to an already-formed material (a textile sheet) to enhance its surface properties like lustre and smoothness.

Sintering, by contrast, is a formation process. It fuses loose particles into a solid, dense mass by applying heat and pressure below the melting point, fundamentally changing the material's state from particulate to solid.

The Mechanism: Physical Pressing vs. Binding

The calendering effect is achieved by physically pressing and deforming existing fibers. The structure is held in place by temporary thermal setting.

Pelleting also uses heat and pressure, but its goal is to agglomerate feedstock into dense pellets. It relies on a binder (like lignin in biomass) plasticizing to glue the material together upon cooling, creating entirely new, discrete forms.

The Permanence: Temporary vs. Lasting

The most critical distinction is permanence. The effects of calendering are mechanical and temporary, typically lost after the first wash as fibers swell and return to their natural state.

The consolidation achieved through sintering and the binding in pelleting are designed to be permanent structural changes.

Applying This Principle to Your Project

Understanding the temporary nature of calendering is essential for its correct application. It is a tool for aesthetic and surface enhancement, not for creating permanent structural properties.

- If your primary focus is enhancing aesthetic appeal: Calendering is an excellent choice for creating a high-lustre, smooth surface on fabrics for a premium appearance.

- If your primary focus is creating a solid mass from powder: You should use sintering, as it is designed to reduce porosity and form a dense, solid part.

- If your primary focus is forming discrete, dense units: Pelleting is the correct process, as it agglomerates feedstock into a new, compact form using a binder.

By recognizing that calendering is a tool for surface finishing, you can apply it precisely for its intended purpose of enhancement, not permanent transformation.

Summary Table:

| Key Element | Role in Calendering | Effect on Fabric |

|---|---|---|

| Pressure | Flattens yarns and fibers | Creates a smoother, denser surface |

| Heat | Makes fibers pliable and sets the finish | Enhances lustre and smoothness |

| Moisture | Relaxes fibers for uniform processing | Ensures even application of heat and pressure |

Need precise surface finishing solutions for your materials? KINTEK specializes in advanced laboratory equipment and consumables tailored for textile and material testing. Whether you're researching fabric treatments or developing new finishing processes, our tools deliver the accuracy and reliability you need. Contact our experts today to explore how KINTEK can support your project with cutting-edge technology and industry expertise!

Visual Guide

Related Products

- Small Lab Rubber Calendering Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Vacuum Cold Mounting Machine for Sample Preparation

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

People Also Ask

- What is pyrolysis of rubber? Transform Waste Tires into Oil, Carbon & Gas

- What is the working principle of rolling mill? It Depends on Your Material Processing Goal

- What is the use of a blown film machine? To Produce Strong, Versatile Plastic Films for Packaging

- What is the difference between extrusion and co-extrusion? Engineer Multi-Material Parts

- What is the blown film technique? A Guide to High-Strength Plastic Film Production

- What are the advantages of a two-high rolling mill? Cost-Effective Durability for Heavy Reduction

- What to do with injection molding? Mass-Produce High-Quality Plastic Parts Efficiently

- What are the two basic types of extrusion? Hot vs. Cold Extrusion Explained